Device for purifying the exhaust gases of diesel engines

一种柴油机、柴油的技术,应用在排气装置、消音装置、电气控制等方向,能够解决噪声增高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

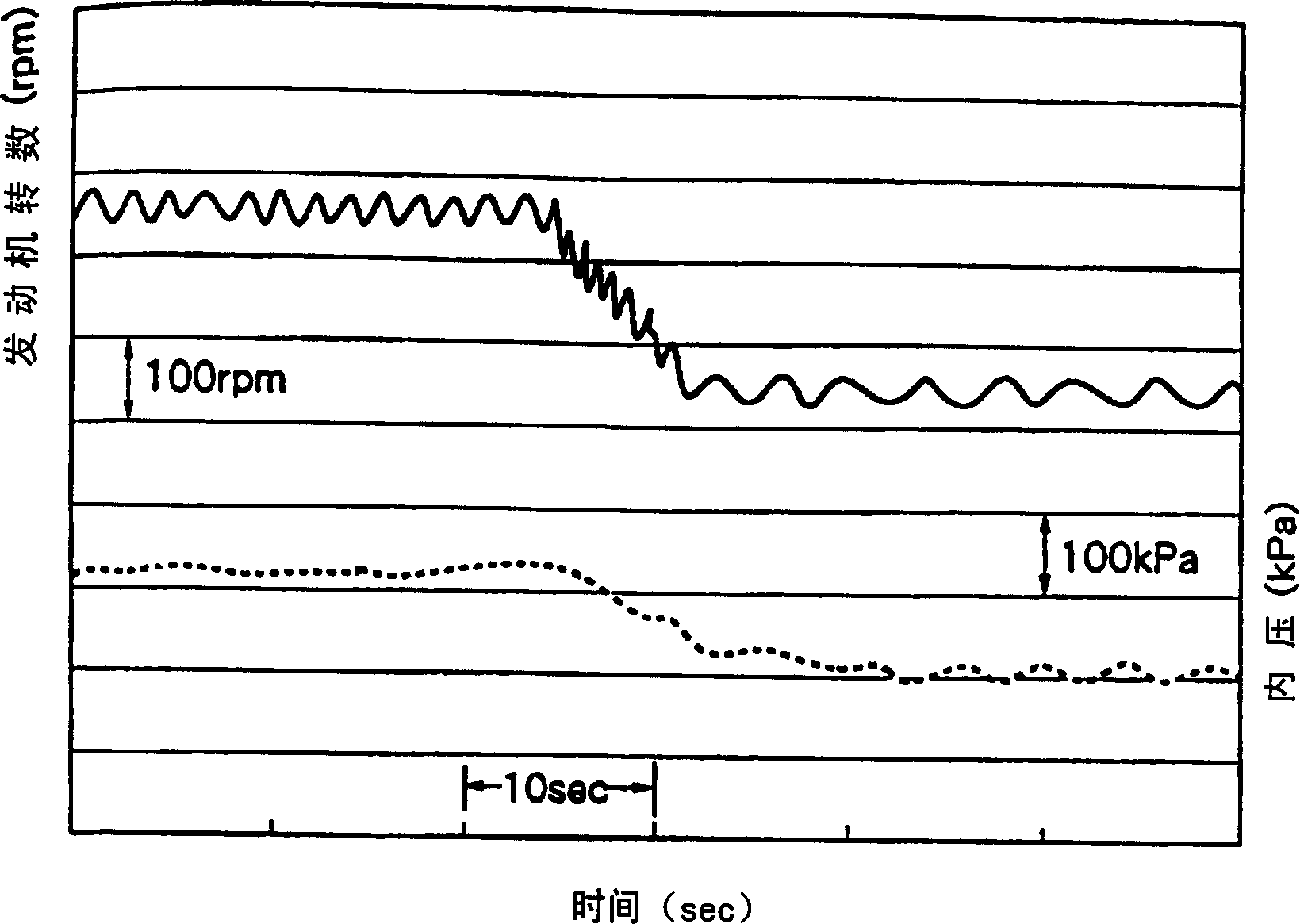

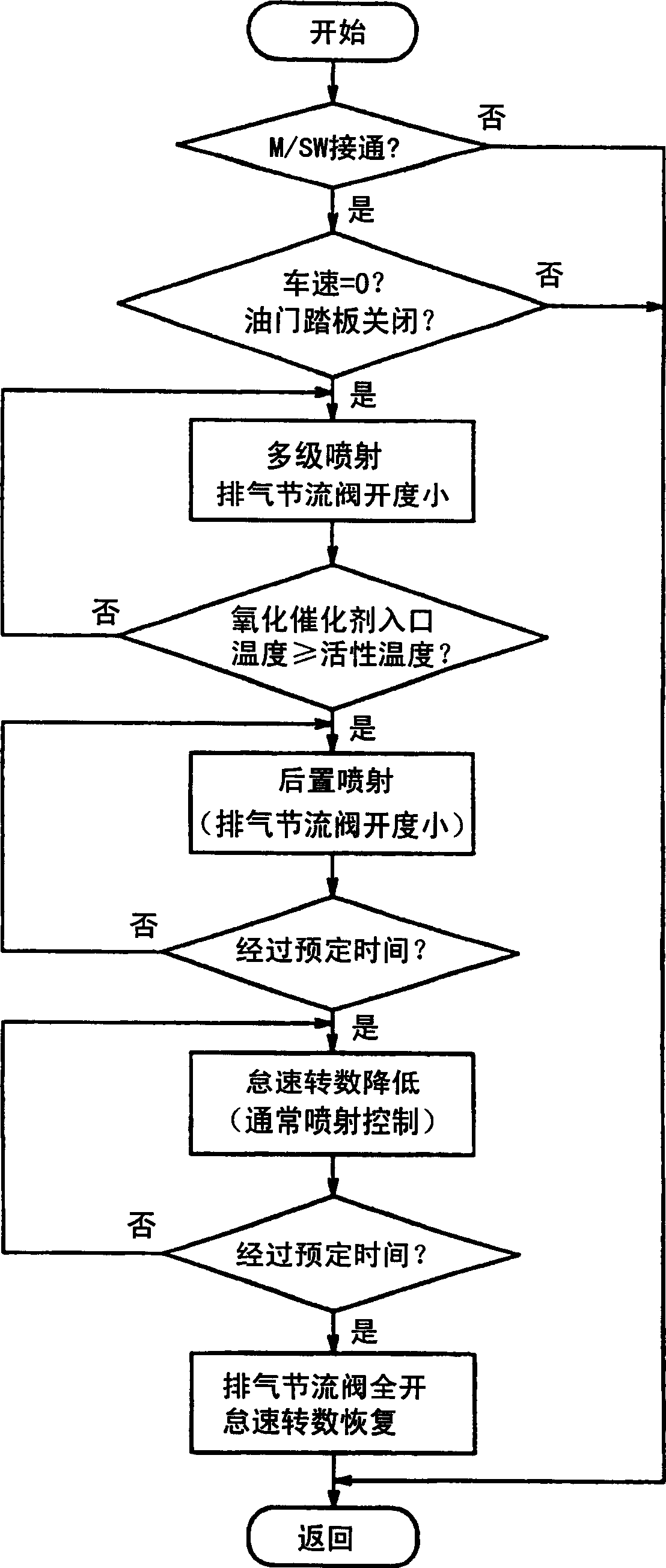

[0036] Hereinafter, an exhaust gas aftertreatment device for a diesel engine according to the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram of the exhaust gas post-treatment device of the diesel engine of the present invention, which is different from the previous example ( Figure 5 ) and corresponding parts of the device are marked with the same symbols. figure 2 It is a graph showing the number of revolutions of the diesel engine and the change in the internal pressure of the continuous regeneration type DPF when the control according to the present invention is implemented.

[0037] Basic equipment constituting the exhaust gas aftertreatment device of the diesel engine of the present invention and its operation and Figure 5 The prior devices shown are not particularly different. That is, in the cylinder of the diesel engine body 1 , the fuel injected from the fuel nozzle 4 is mixed with the air supplied from the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com