Hot rolling method and apparatus for hot steel sheet

A technology of steel plates and heaters, applied in workpiece heating devices, metal rolling, metal rolling, etc., can solve problems such as incompensation, large heaters, and insufficient temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

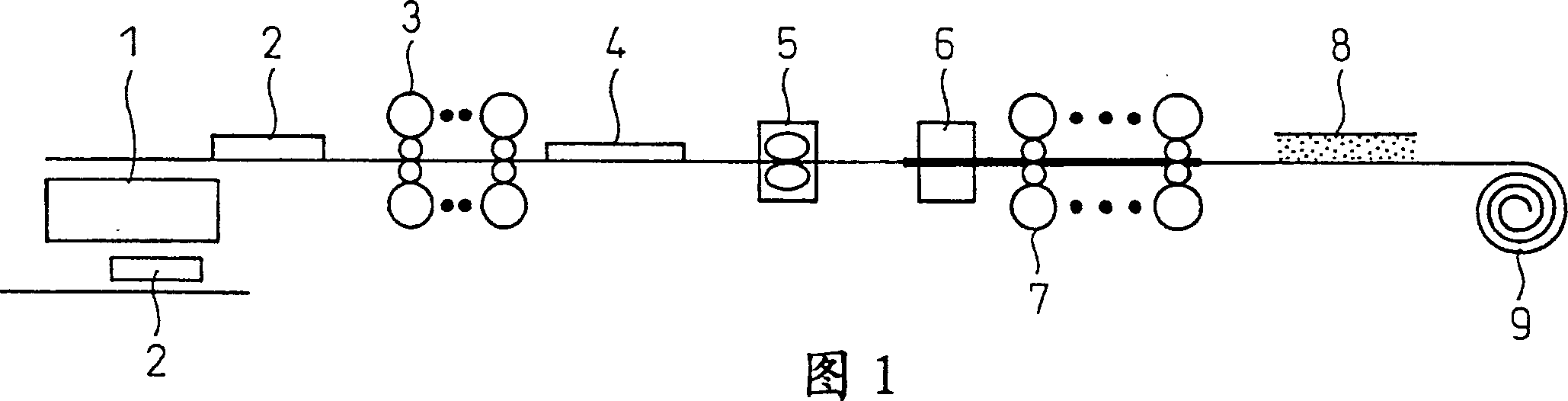

no. 1 example

[0092] It is known that when obtaining a hot-rolled steel sheet with predetermined material properties in the width direction, that is, no change in material (properties) in the width direction, the temperature in the width direction of the rough bar on the feed side of the finishing mill must be adjusted to The distribution plot remains uniform. In the past, it was thought that if an edge heater was used to increase the temperature of the temperature drop portion of both edges of the rough bar caused by rough rolling, the temperature profile in the width direction of the rough bar would become uniform.

[0093] However, the material properties of the finish-rolled hot-rolled steel sheet vary in the width direction after heating both edges of the rough bar with an edge heater.

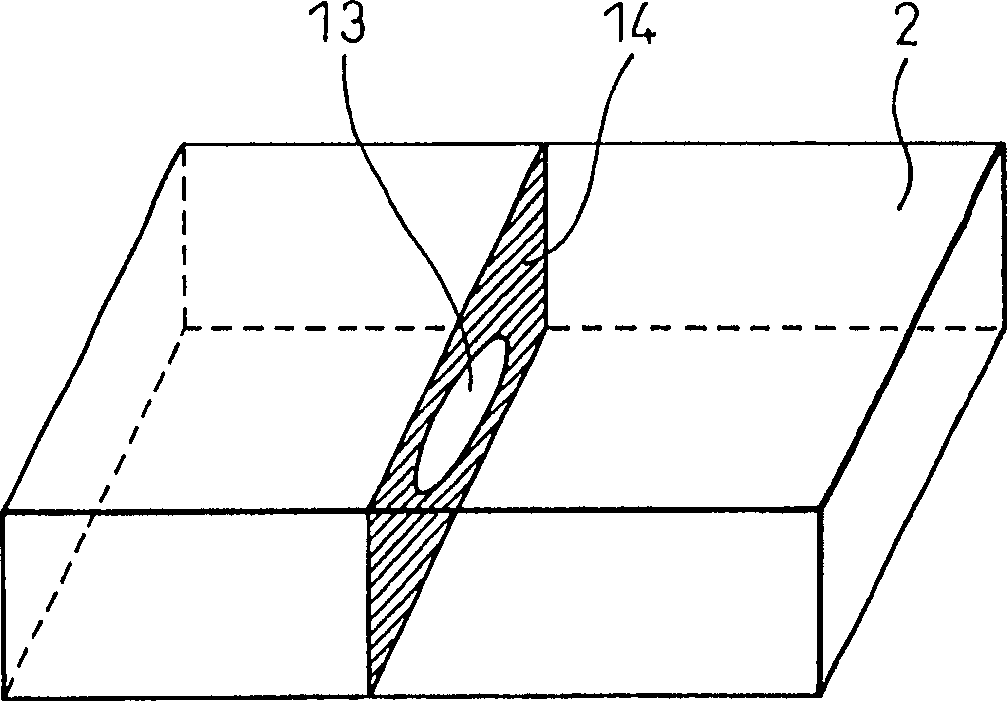

[0094] Therefore, the inventors conducted various experiments to find the cause, and as a result, found that the cause was present when the slab was heated in the heating furnace.

[0095] That is, b...

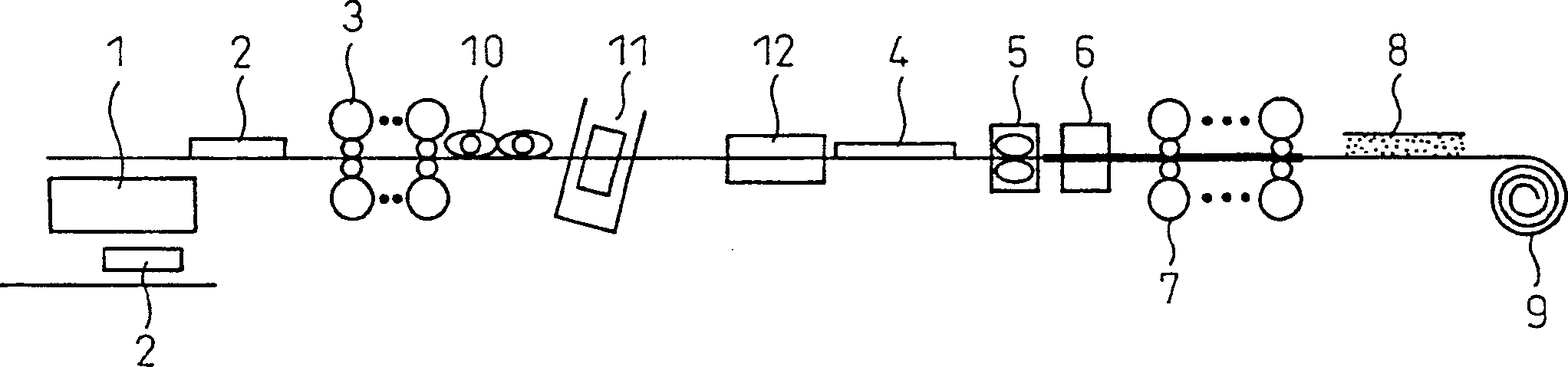

no. 2 example

[0119] In addition, the inventors have also found that if the finish rolling is performed so that there is a temperature difference in the width direction of the steel sheet before the finish rolling is performed to produce a special steel sheet having different characteristics in the width direction of the steel strip, especially the hole expansion characteristic and the elongation characteristic, , then through hot rolling, the hole expansion characteristics of the steel plate can be effectively improved by using the hot finish rolling temperature.

[0120]For example, when a high tensile strength steel strip of the 590 MPa grade comprising 0.09 to 0.11% carbon, 1.30 to 1.50% silicon, 1.25 to 1.45% manganese, not more than 0.010% phosphorus and not more than 0.002% sulfur is applied In the case of beams or other automobile parts, this part is cut in the width direction of the steel strip. From the shape of this part (derived), the main processing is reaming forming near the ...

no. 3 example

[0136] In the hot rolling device shown in Fig. 1, two transverse induction heaters 2 having different core widths are provided, that is, a transverse induction heater 23 with a core width greater than that of the rough bar 4 and a core A transverse induction heater 24 with a width smaller than that of the rough bar is provided with an edge heater 6 to form a hot rolling device.

[0137] A thermometer 22 in the width direction of the feed side is arranged on the feed side of the two transverse induction heaters with different core widths, and a thermometer 25 in the width direction of the discharge side is arranged on the discharge side. The rough bar 4 rolled by a roughing mill is conveyed in the direction of the arrow by conveying rollers. Use the feed side width direction thermometer 22 to measure the temperature profile in the width direction of the crude rod 4, then use the temperature rise controller to determine the temperature distribution due to the transverse inductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com