Non contact flexible magnetic coupling for vacuum system

A magnetic coupling and vacuum system technology, which is applied in the field of power transmission equipment and flexible magnetic couplings, can solve the problems of small transmission torque, large transmission torque, and small magnetic field strength, and achieve large transmission torque, Small size, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Power transmission in material preparation equipment for high vacuum systems.

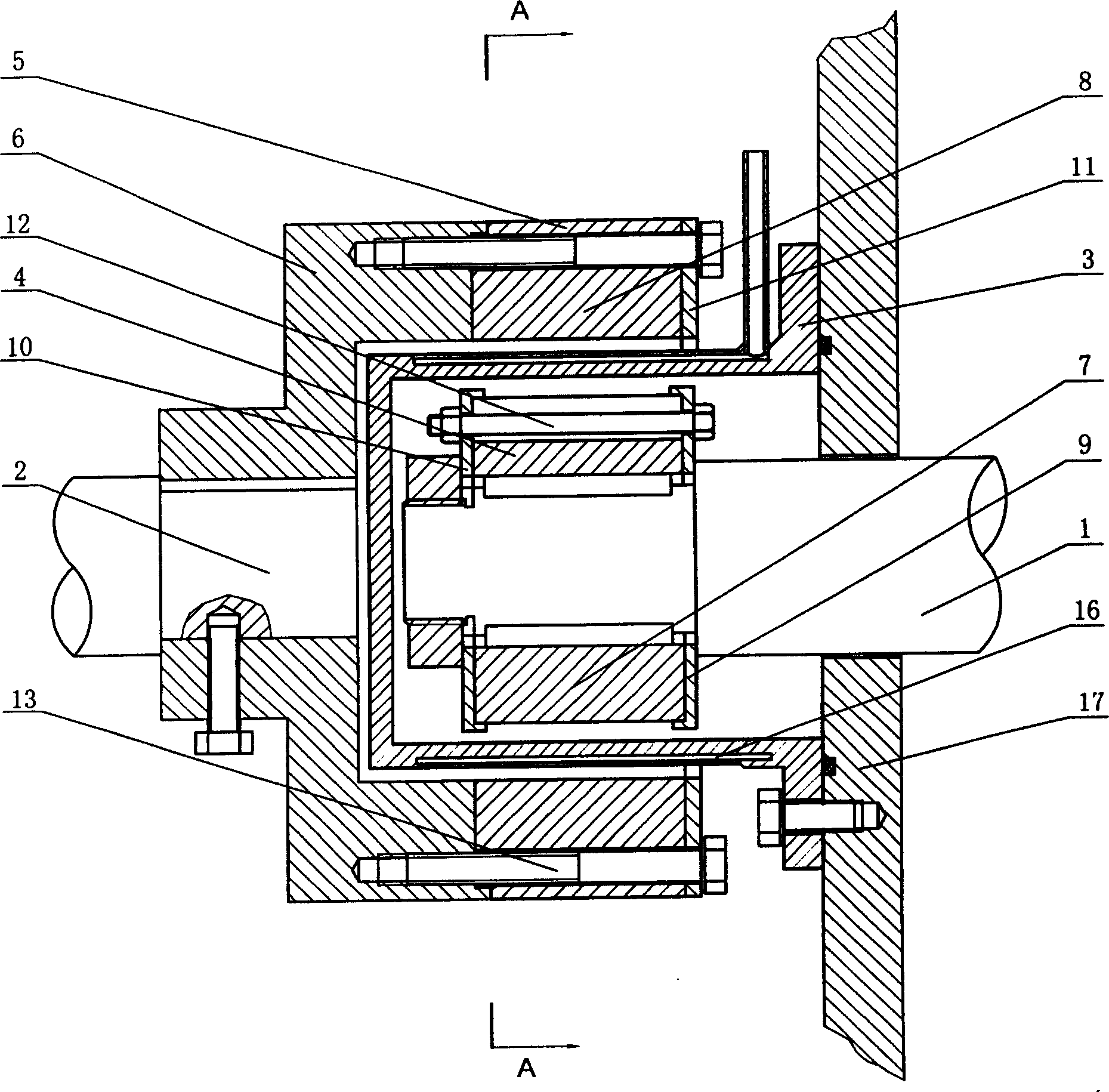

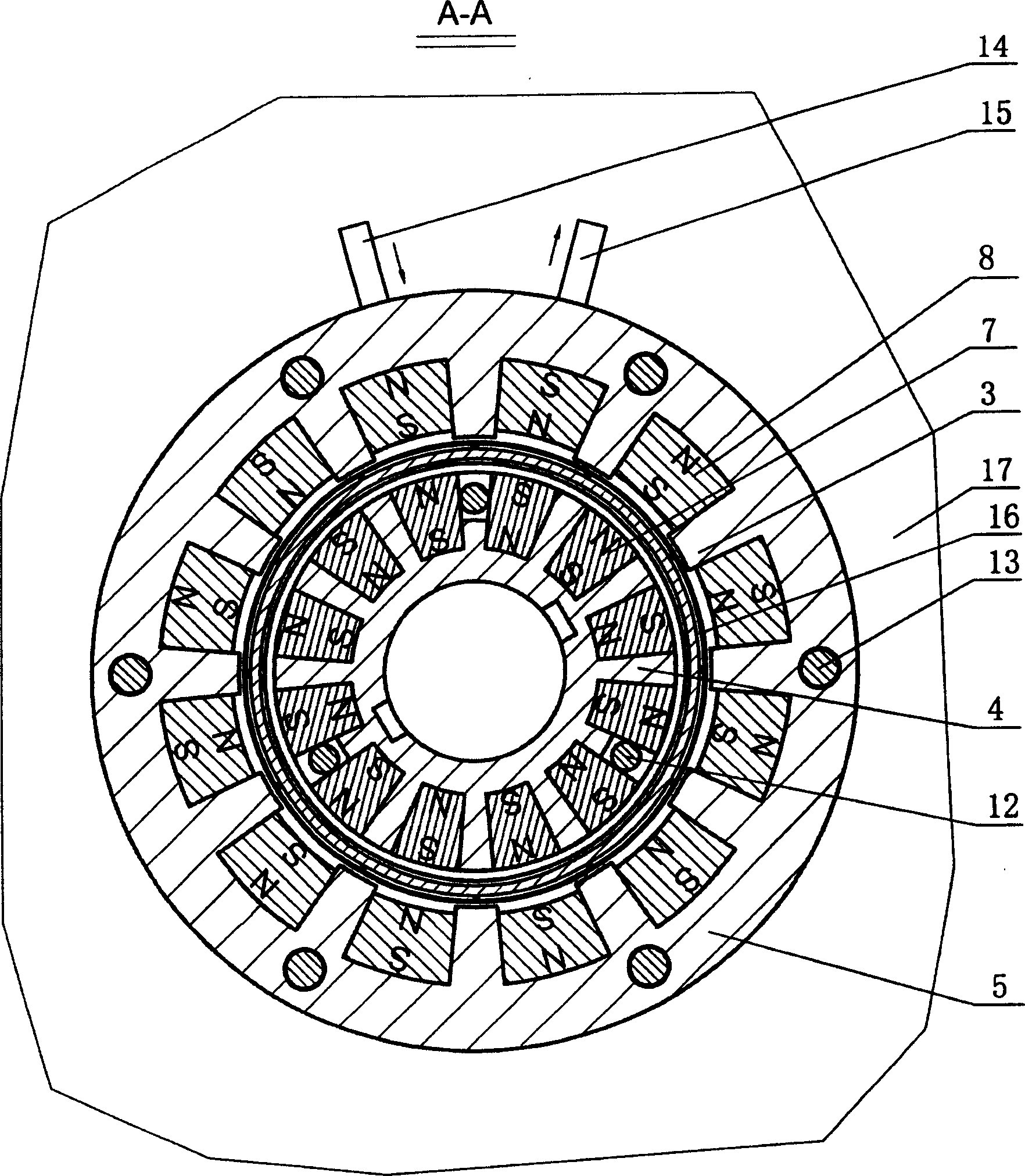

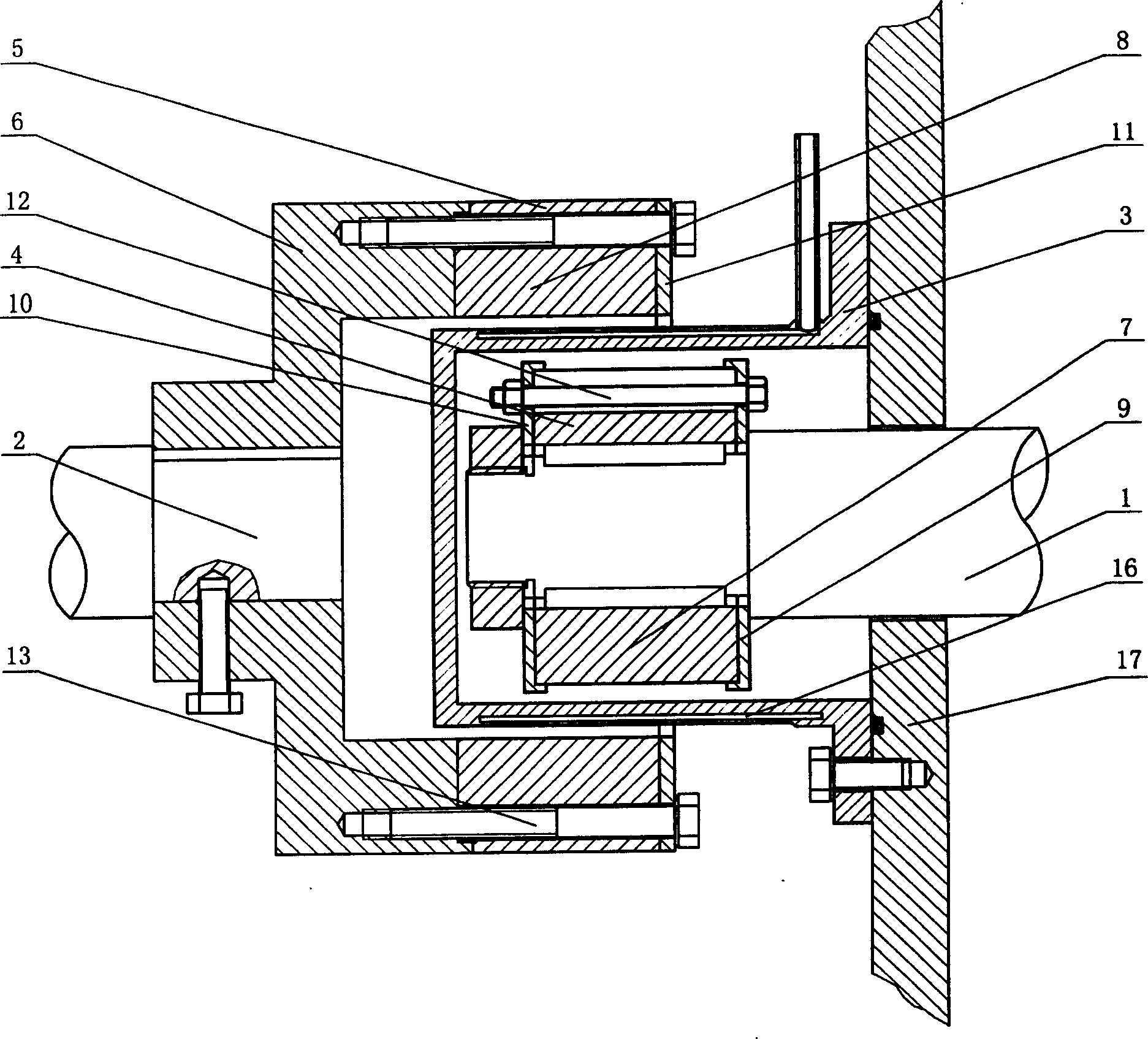

[0033] The inner magnetic strip fixing frame 4, the outer magnetic strip fixing frame 5, the outer gland 9, the inner gland 10, the active connection plate 6, and the partition cover 3 are all made of stainless steel.

[0034] Fix the partition cover 3 on the vacuum chamber side wall 17 of the vacuum system with bolts, and the partition cover 3 will pass through the vacuum chamber side wall 17 to protrude from the driven shaft 1 outside the vacuum chamber and the driven half coupling mounted on the driven shaft. The shaft is sealed to form a closed vacuum system, and the embedding depth of the driven magnetic half coupling in the active magnetic half coupling is adjusted. Feed circulating cooling water with a pressure of 0.1 MPa and a flow rate of 0.5 tons / hour into the shield 3, turn on the mechanical pump of the high vacuum system, and when the pressure is less than 40Pa, turn on the diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com