Static yarn-flocking device and method

An electrostatic flocking and production method technology, which is applied to the surface coating device and coating, can solve the problems of pollution, fluff easy to fall off, low production efficiency, etc., and achieve a clean production environment, high flocking density, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

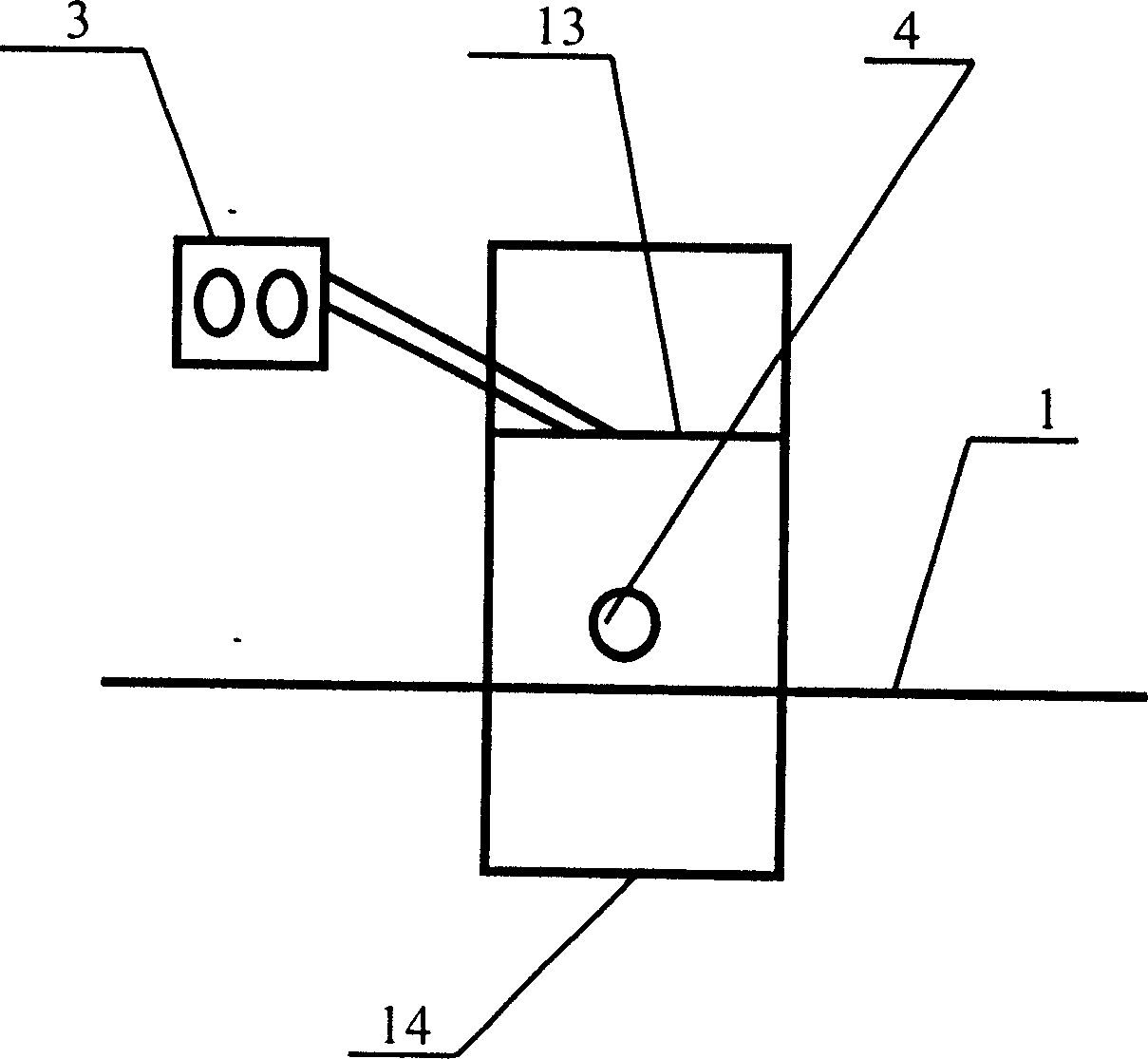

[0024] Production device and method of the present invention are described in detail below in conjunction with accompanying drawing:

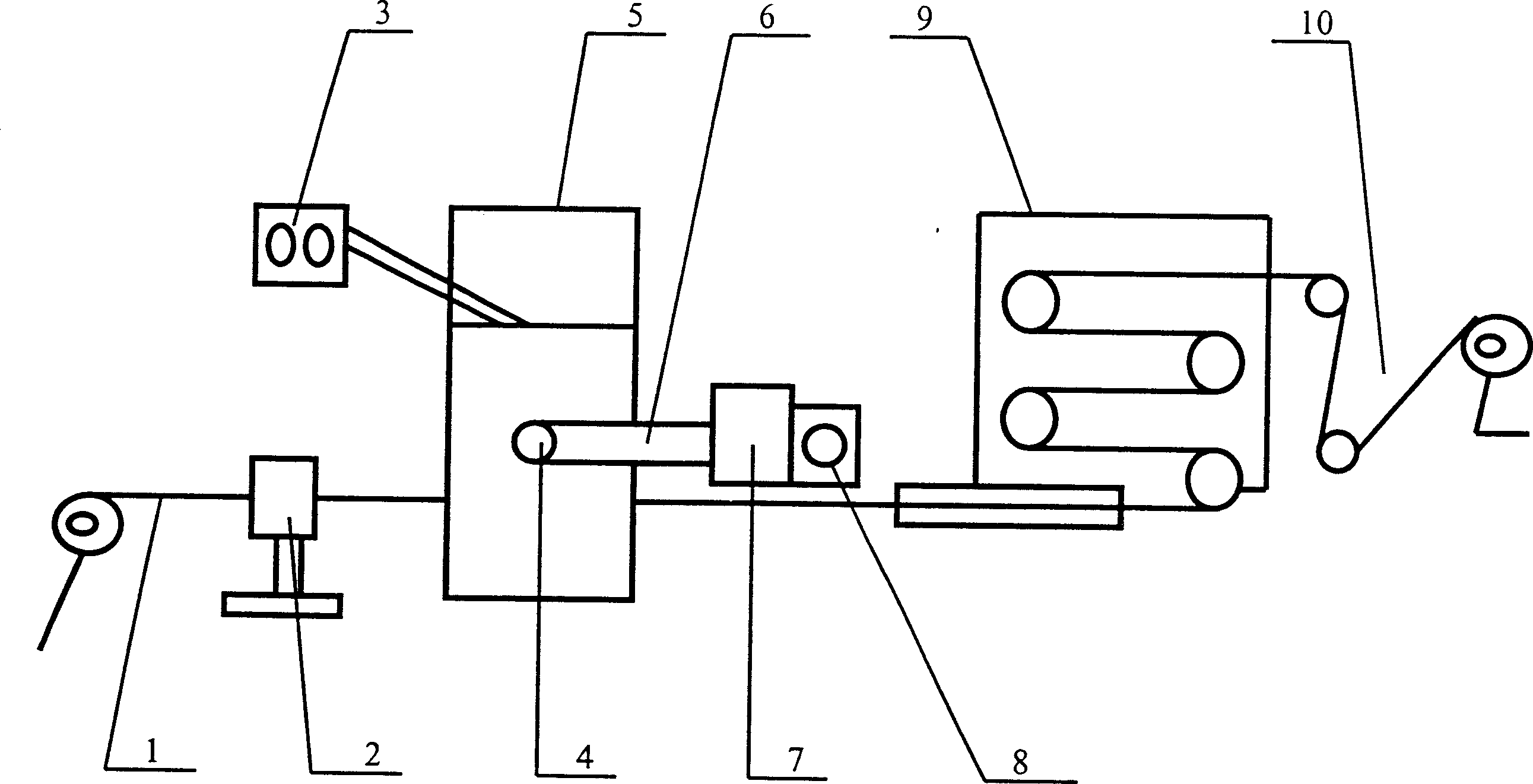

[0025] Such as figure 1 , the electrostatic flocking device includes an adhesive yarn applicator 2, a high-voltage electrostatic generator 3, a casing 7 filled with fluff, a blower 8, an electrostatic flocking box 5, a drying device 9 and a take-up device 10, which form a day Complete yarn flocking production line.

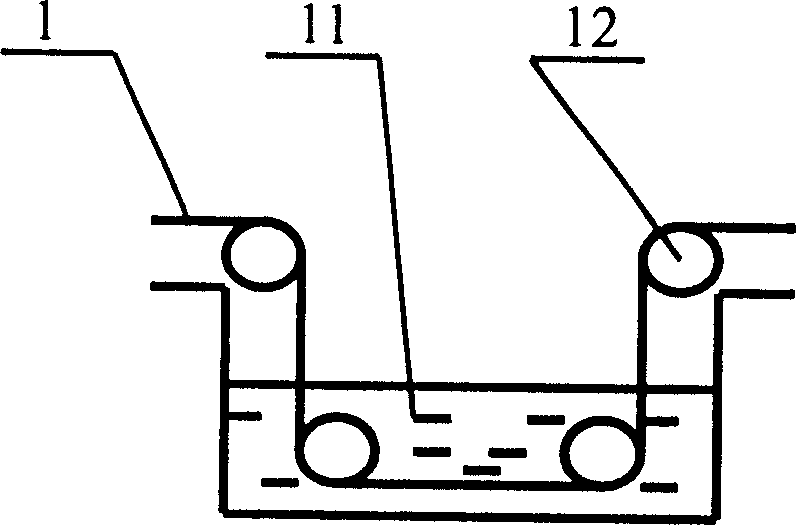

[0026] Such as figure 2 , The inside of the yarn applicator 2 is a square groove structure, the groove is filled with adhesive 11, and the liquid surface of adhesive 11 is lower than the notch, so that adhesive 11 will not overflow from the entrance and exit, causing pollution. There are four pulleys 12 inside the slot, two of which are installed at the entrance and exit respectively, and they guide the yarn 1 to enter and output; there are two pulleys 12 submerged in the adhesive 11 in the slot, and they guide The yarn 1 enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com