Method to correct for sensitivity variation of media sensors

A sensor and sensitivity technology, which is applied in the field of correcting the sensitivity change of media sensors, can solve problems such as difficult to produce reliable test tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

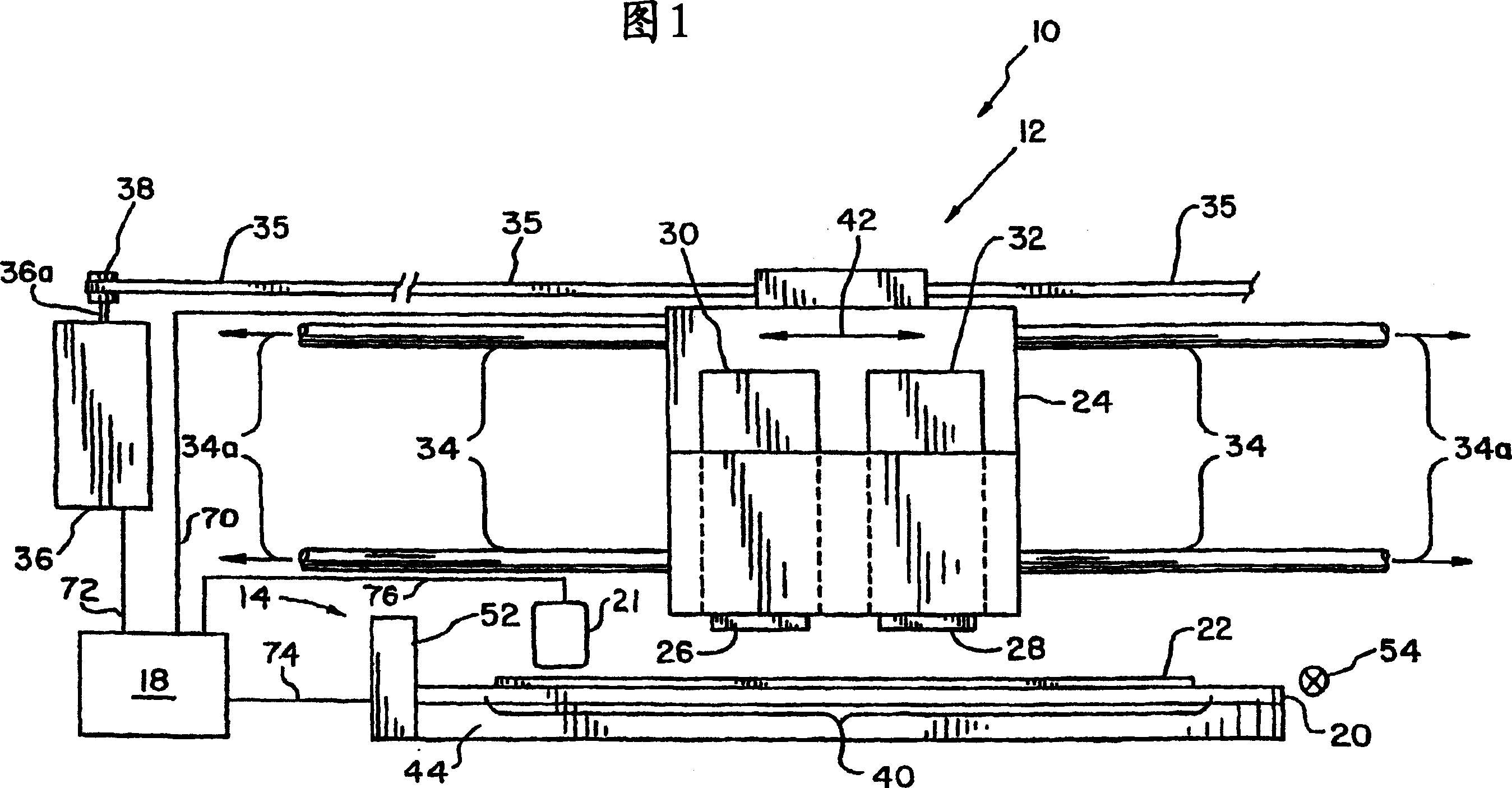

[0028] Referring now to the drawings, and particularly to FIG. 1, there is shown an inkjet printer 10 embodying the present invention. The inkjet printer 10 includes a printhead carrier system 12 , a feed roller unit 12 , a controller 18 , a mid-frame 20 and a media sensor 21 .

[0029] The printhead carrier system 12 includes a printhead carrier 24 for carrying a color printhead 26 and a black printhead 28 . A color ink reservoir 30 is provided in fluid communication with the color printhead 26 and a black ink reservoir 32 is in fluid communication with the black printhead 28 . The printhead carrier system 12 and printheads 26, 28 may be configured for unidirectional printing or bidirectional printing.

[0030] The printhead carrier 24 is guided by a pair of guide rods 34 . The axis 34a of the guide rod 34 defines the bi-directional scan path of the printhead carrier 24, so for convenience, the bi-directional scan path will be referred to as the bi-directional scan path 34a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com