Optical module, manufacturing method therefor, protective component for a light guide, and protective component having electric wiring

A technology of optical modules and electrical wiring, applied in the field of optical modules, can solve the problems of unfavorable size reduction and cost reduction, and achieve the effects of size reduction, cost reduction, and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

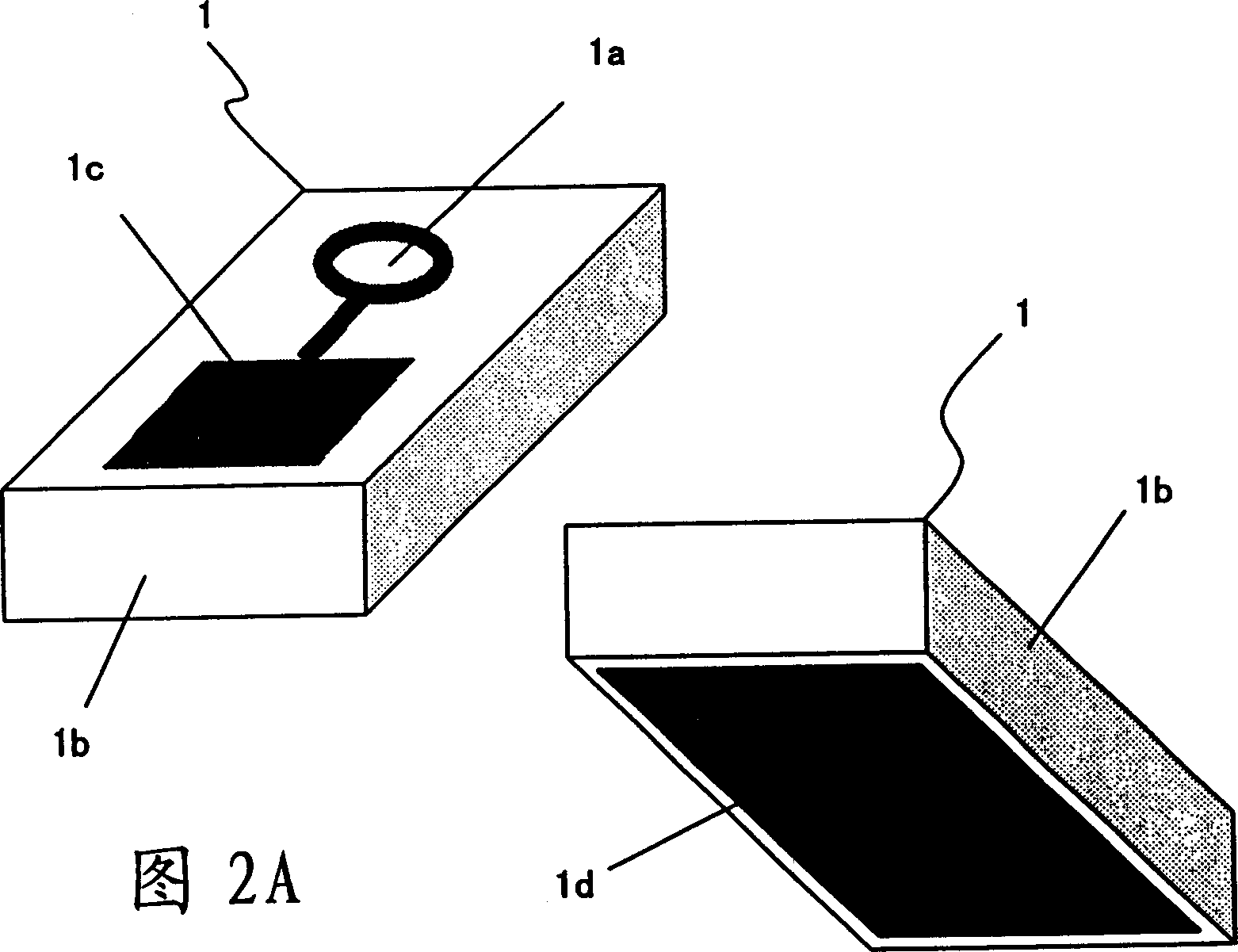

[0040] figure 1 is a partially transparent side view illustrating the construction of an optical module according to a first embodiment of the invention. 2(A) and 2(B) are perspective views schematically showing optical elements used as main components of the optical module, image 3 is a perspective view schematically showing a base (an optical element mounting substrate) on which the optical element is loaded (mounted), and Figure 4 is a perspective view schematically showing a holder serving as a main component of the optical module.

[0041] exist figure 1 Among them, the optical module includes the following main components: a base 8 on which an optical element 1 is mounted, for example, a light-emitting element such as an LD or a light-receiving element such as a PD, which are used to perform photoelectric conversion; and a sheath (protective component )3, used to protect optical fibers used as optical transmission media. In addition, in figure 1 In , reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com