Organosilicon modified acrylate emulsion for ambient temperature crosslinked aqueous paint and method for preparing same

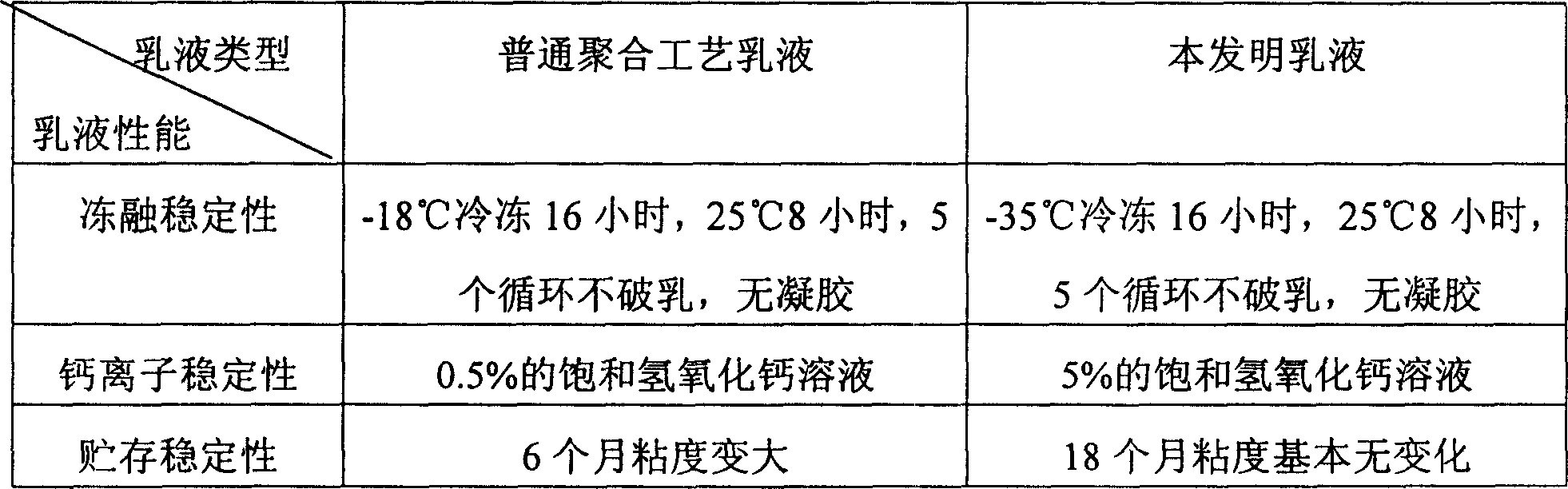

An ambient temperature, acrylate technology, applied in the field of chemical coatings, can solve the problems of freeze-thaw stability, calcium ion stability and insufficient storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Silicone-modified acrylate emulsion modified by inorganic nanoparticles

[0058] The preparation method is as follows:

[0059] (1) Synthesis of silicone prepolymer:

[0060] 400 kg of isopropanol and 8.4 kg of dry potassium hydroxide were added to the reactor, heated to reflux, and 350 kg of isopropanol was distilled off. Then add 148 kilograms of octamethylcyclotetrasiloxane (D 4 ), react at 100-120°C for 120 minutes, then cool down to 70-80°C, add 10 kg of glacial acetic acid, stir for 60 minutes, then vacuumize to remove small molecules, filter, and remove potassium acetate to obtain silicone prepolymer Object A. spare.

[0061] (2), add 70 kg of tetraethyl orthosilicate to the reaction kettle, add dropwise 6 kg of deionized water and 0.2 kg of glacial acetic acid, and react at 90°C for 60 minutes, then use a water pump to remove the residual water and ice in the system. Acetic acid and a small amount of ethanol, then add organosilicon prepolymer A, ...

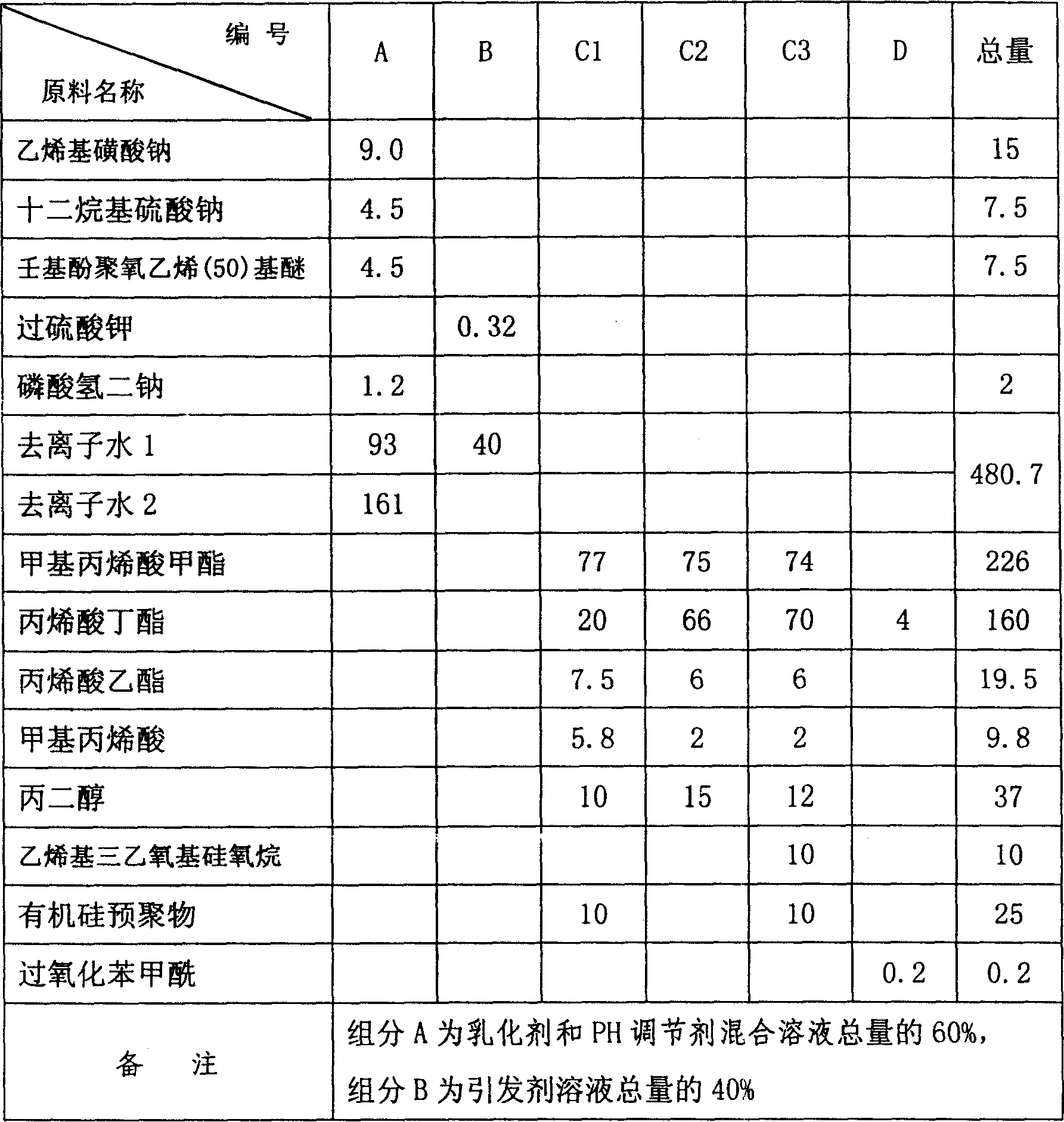

Embodiment 2

[0068] Embodiment 2, is identical with the technique of embodiment 1, and raw material composition is basically the same, but following change is arranged:

[0069] Formulation unit: kg

[0070]

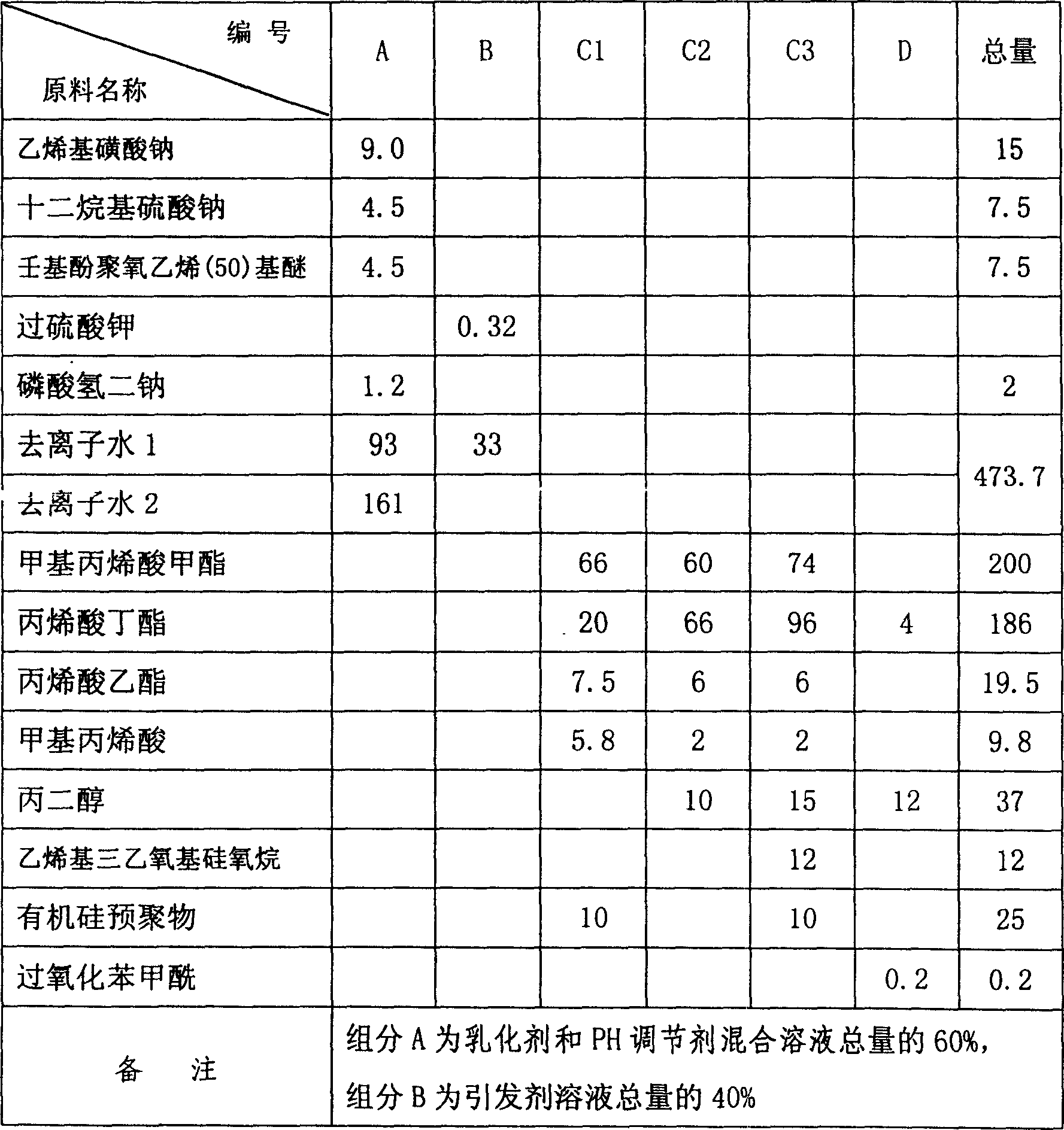

Embodiment 3

[0071] Embodiment 3, the process is identical with embodiment 1, and raw material composition is basically the same, but following change is arranged:

[0072] Formulation unit: kg

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com