Heat exchanger in particular an evaporator for a vehicle air-conditioning unit

A technology for heat exchangers and air conditioning systems, used in evaporators/condensers, heat exchange equipment, refrigerators, etc., can solve problems such as narrow manufacturing tolerances, and achieve the effects of reducing total cost, weight reduction, and low defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

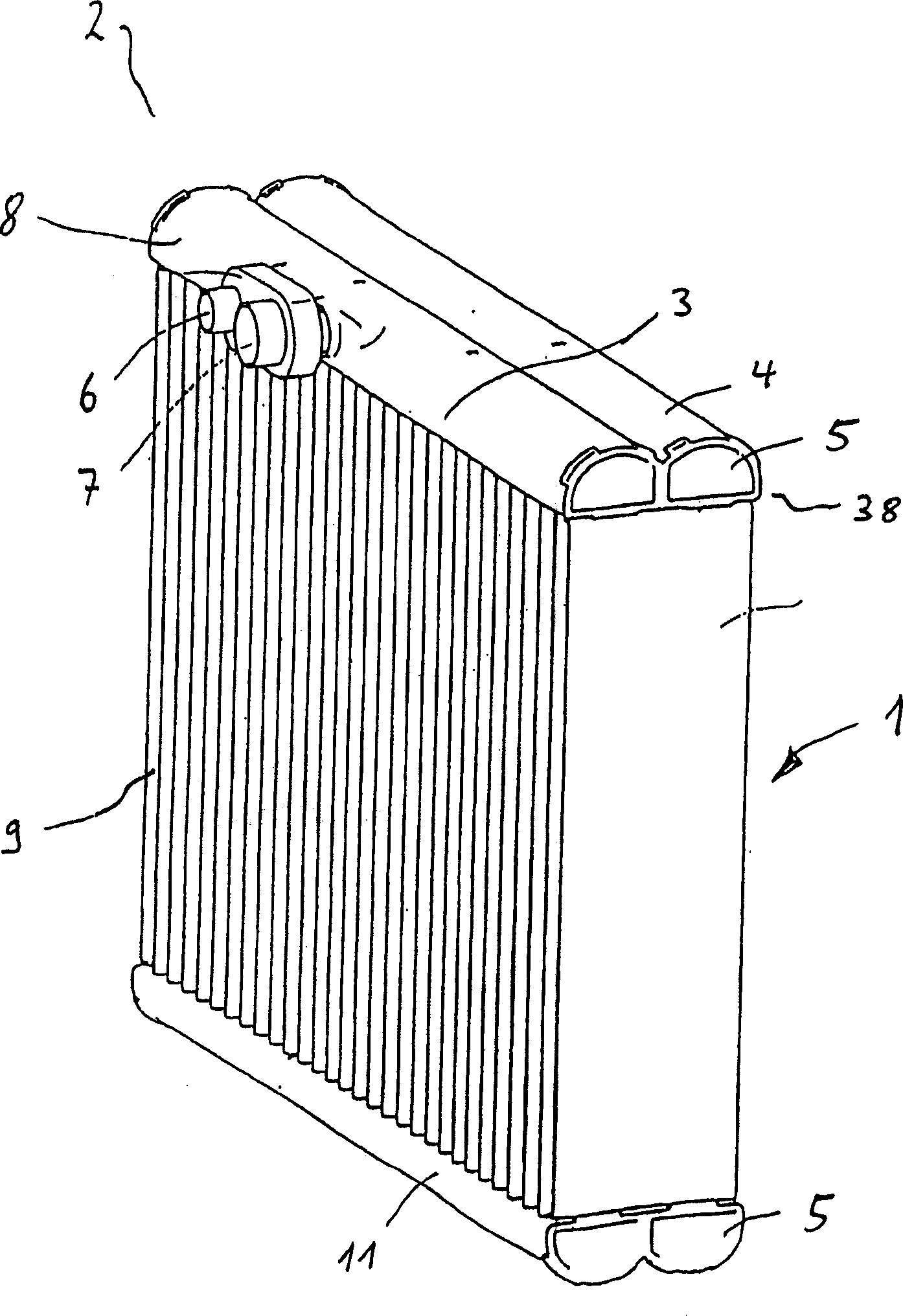

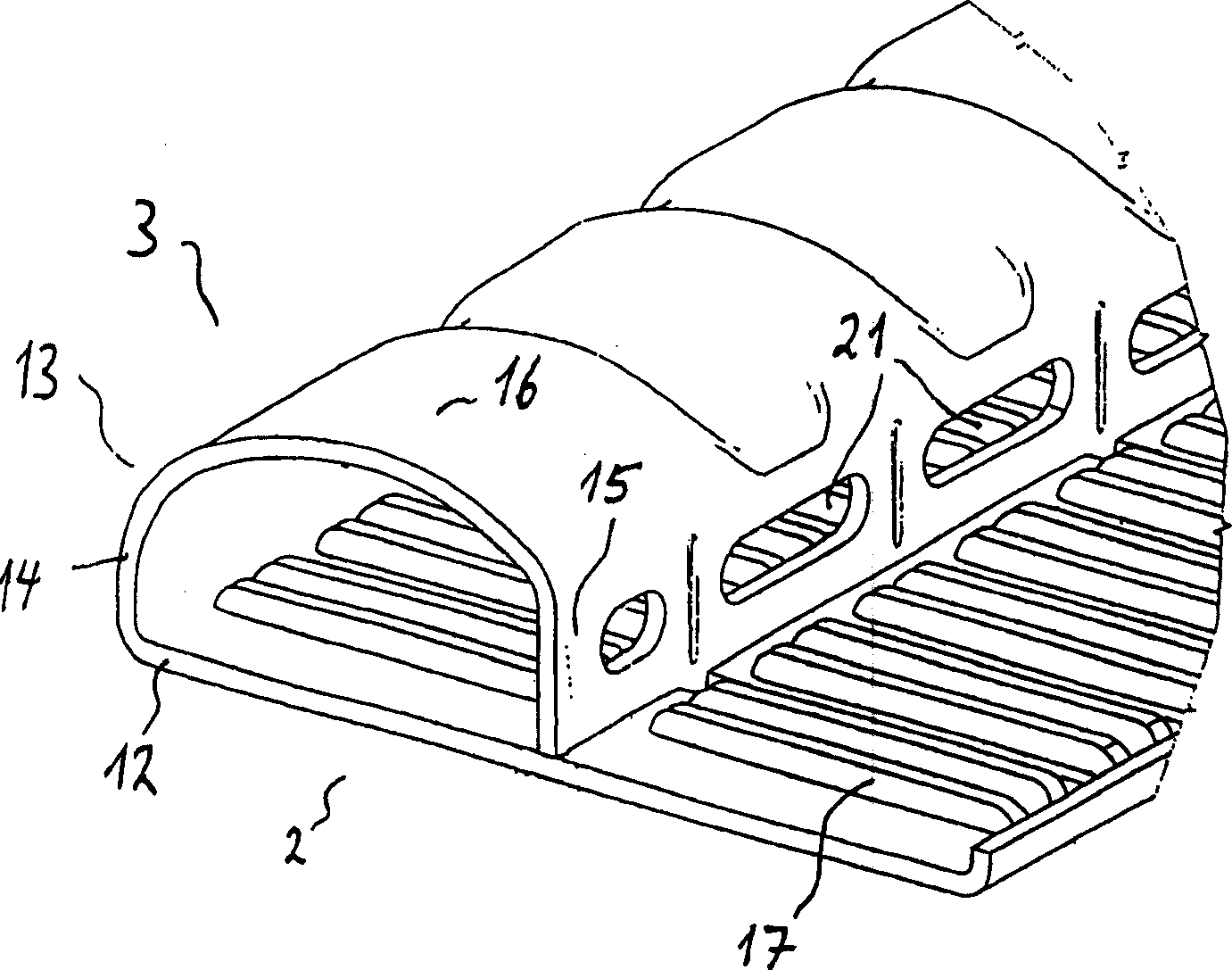

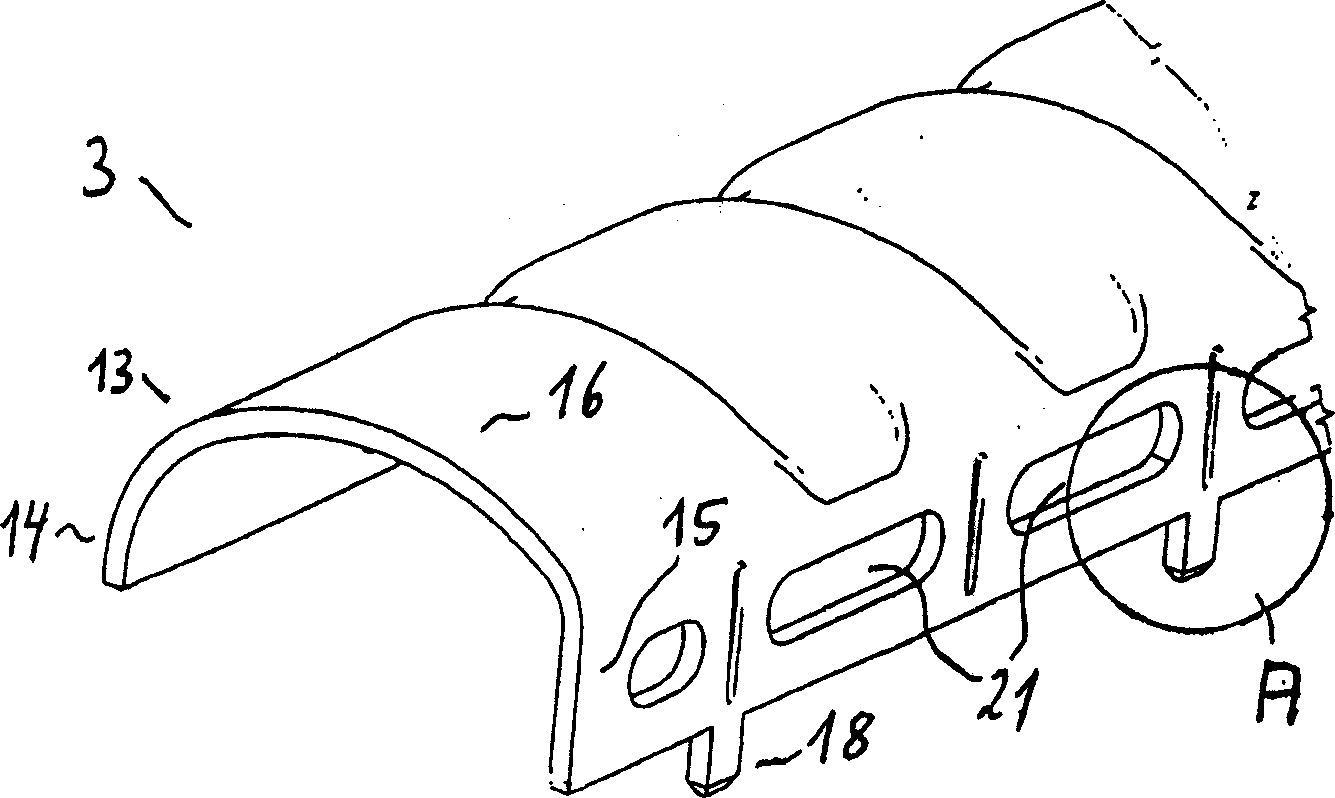

[0068] A first embodiment of the heat exchanger of the invention is configured as an evaporator for an air-conditioning system of a motor vehicle, hereinafter referred to Figure 1-7 to describe in detail.

[0069] figure 1 The heat exchanger shown in the perspective view includes an upper header box 2 and a lower header box 11, with heat transfer tubes 9 disposed therebetween.

[0070] The upper header box 2 includes a first header chamber 3 and a second header chamber 4 parallel thereto, and the end surface of the header chamber is closed by a cover 5 . An inlet 6 and an outlet 7 for evaporating coolant are arranged on one longitudinal side 8 of the first header tank 3 .

[0071] However, it should be pointed out that the inlet and outlet can be provided not only on one or both header tank longitudinal sides 8 of the header tank 3, but it is also possible to arrange the inlet on the first header tank longitudinal side and the outlet on the longitudinal side 8 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com