Double pump-motor hydraulic drive system for a hydraulic motor of engineering machinery

A technology of hydraulic motors and construction machinery, which is applied in the directions of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc. The effect of throttling loss, reducing installed power, and maintaining operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

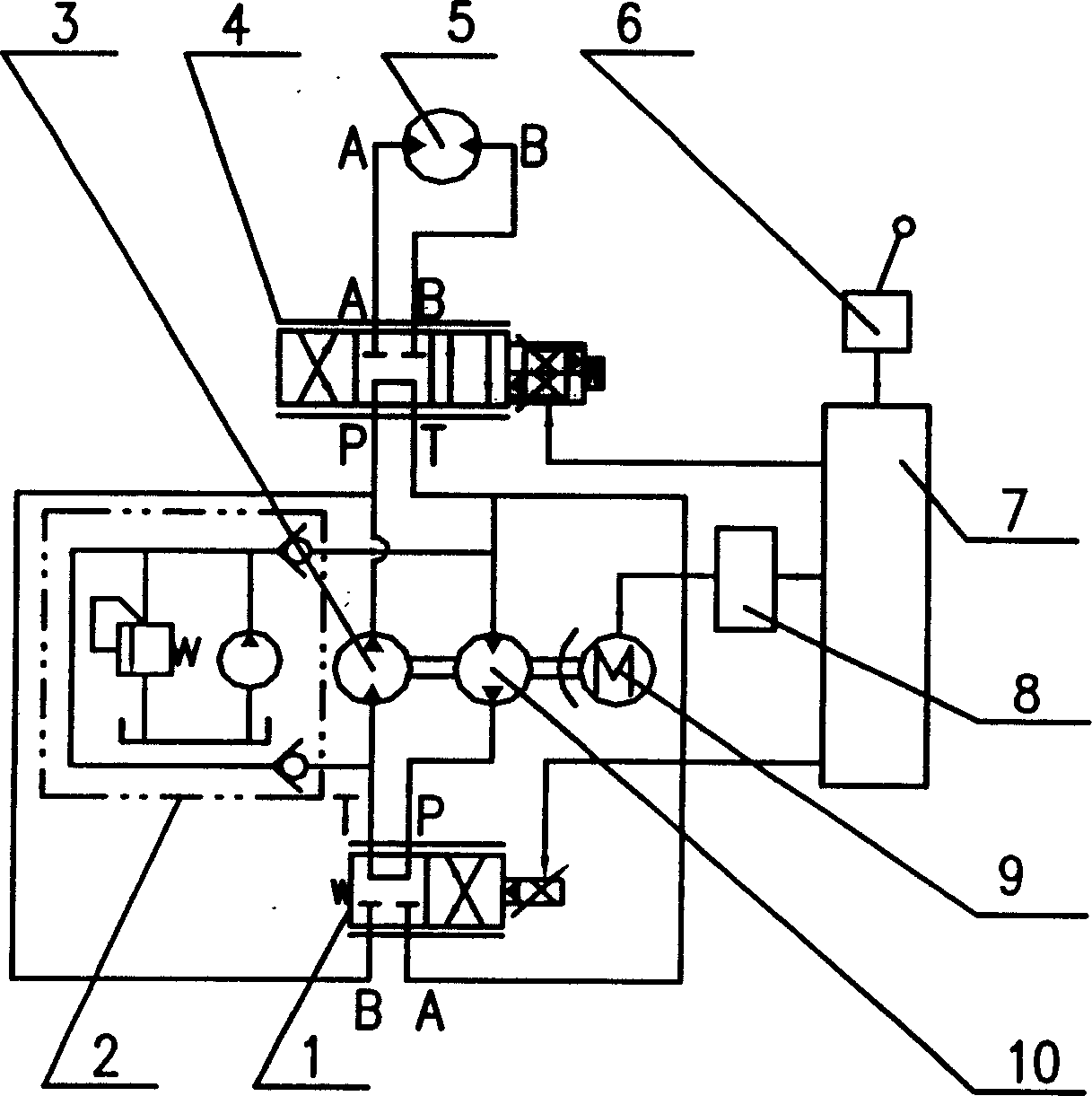

[0023] The present invention includes: speed-increasing valve 1, oil supply system 2, two pumps-motors 3, 10, proportional directional valve 4, hydraulic motor 5, control handle 6, signal control unit 7, frequency converter 8 and frequency conversion motor 9; The interconnection relationship is as follows:

[0024] 1) The variable frequency motor 9 is coaxially connected with the first and second pump-motors 3 and 10 with the same displacement respectively;

[0025] 2) The P port of the proportional directional valve 4 is respectively connected with the oil discharge port of the first pump-motor 3 and the oil port B of the speed-increasing valve 1, and the T port of the proportional directional valve 4 is respectively connected with the oil suction port of the second pump-motor 10 1. The oil outlet of the first one-way valve of the oil supply system 2 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com