Double pump-motor hydraulic driving system for lifting oil cylinder of engineering machine

A technology for lifting oil cylinders and construction machinery, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., which can solve problems such as noise and vibration, energy waste, and life reduction, and reduce throttling losses , reduce the installed power, maintain the effect of operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

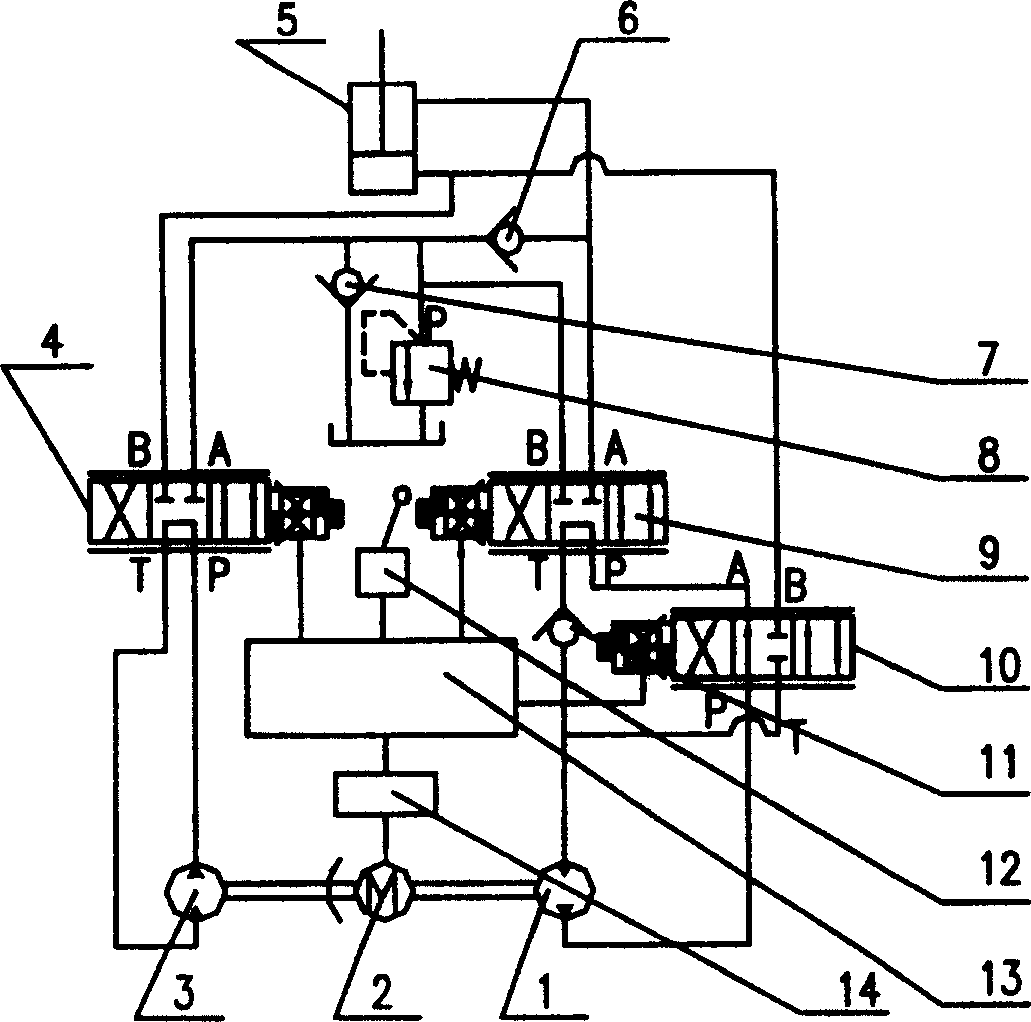

[0023] The present invention includes: two pumps—motors 1, 3, frequency conversion motor 2, two proportional directional valves 4, 9, oil cylinder 5, three one-way valves 6, 7, 11, overflow valve 8, speed-increasing valve 10, Control handle 12, signal control unit 13 and frequency converter 14; their interconnection relationship is as follows:

[0024] 1) The variable frequency motor 2 is coaxially connected with the first and second pump-motors 1 and 3 whose displacement ratio is equal to the area ratio of the two cavities of the oil cylinder 5;

[0025] 2) The P port and T port of the first proportional directional valve 4 are respectively connected with the oil discharge port and the oil suction port of the second pump-motor 3, and the B port of the first proportional directional valve 4 is connected with the rodless cavity of the oil cylinder 5. Port A of a proport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com