Cyclic preheater for single cavity permanent-magnet rotor pump and assembly method thereof

A permanent magnet rotor and pump circulation technology, applied in the direction of machine/engine, engine components, engine starting, etc., can solve problems such as unreasonable overall structure, achieve the effect of reducing the number of parts, reducing manufacturing costs, and simple molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation and examples of the present invention will be described below in conjunction with the accompanying drawings.

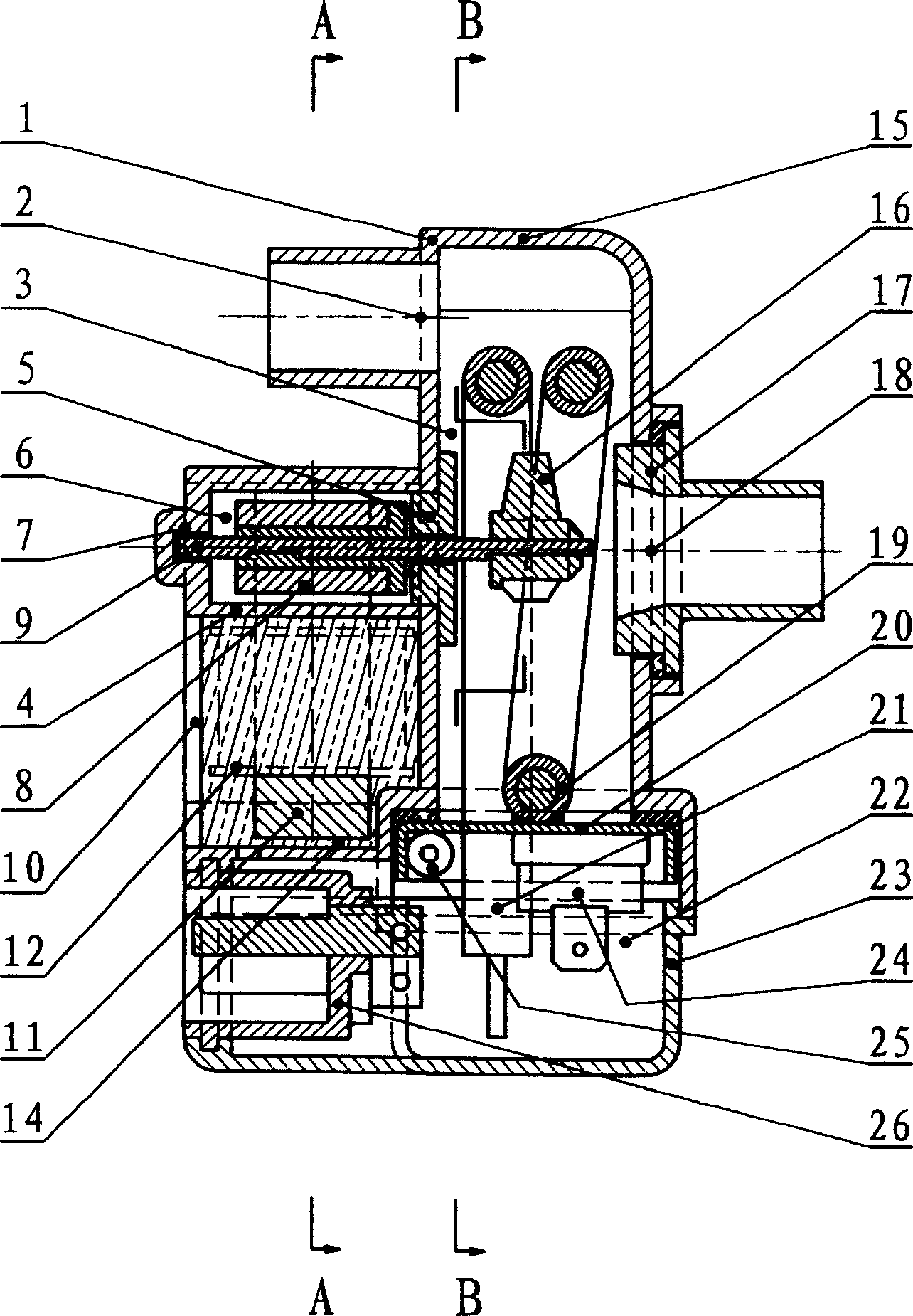

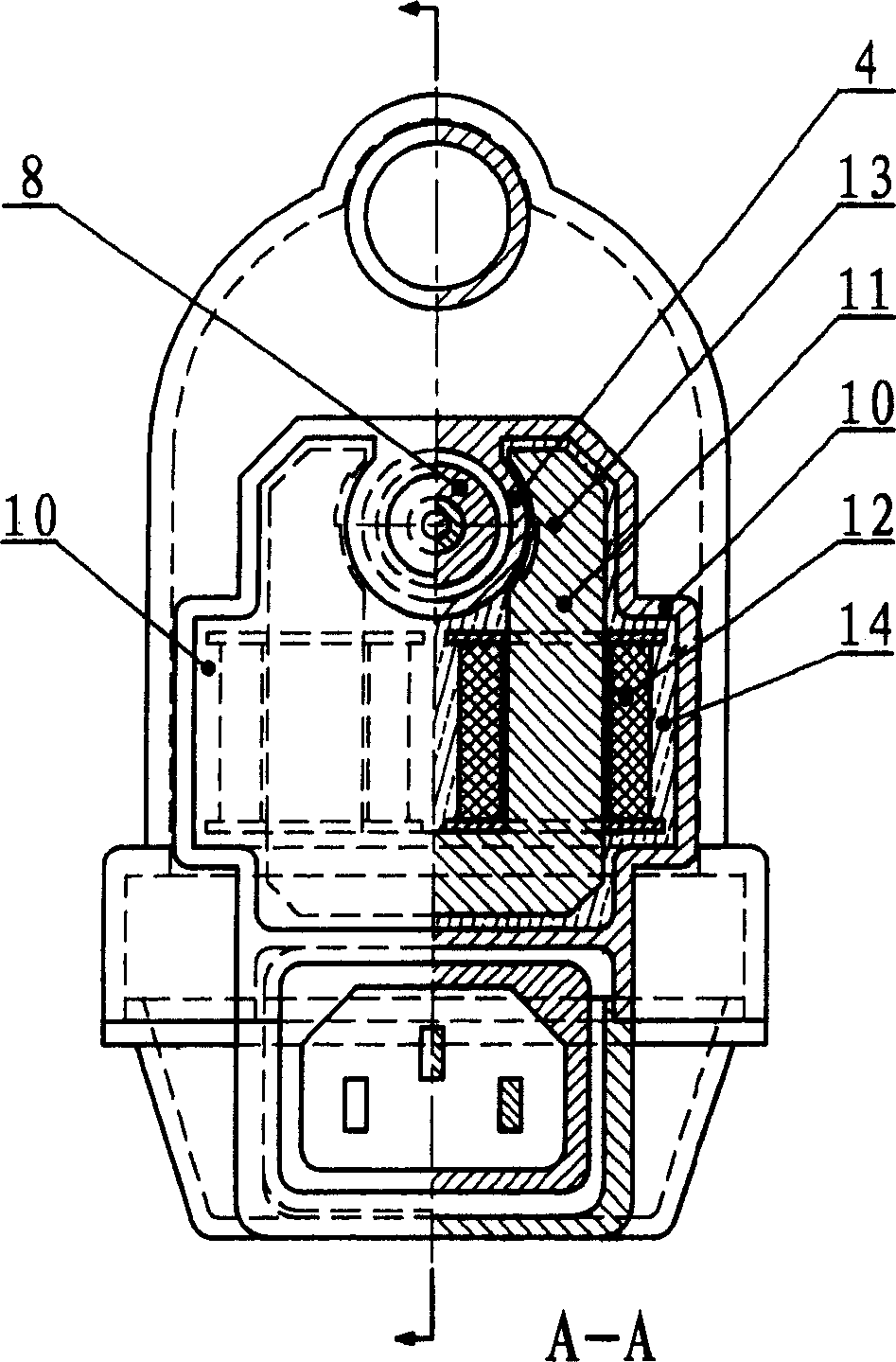

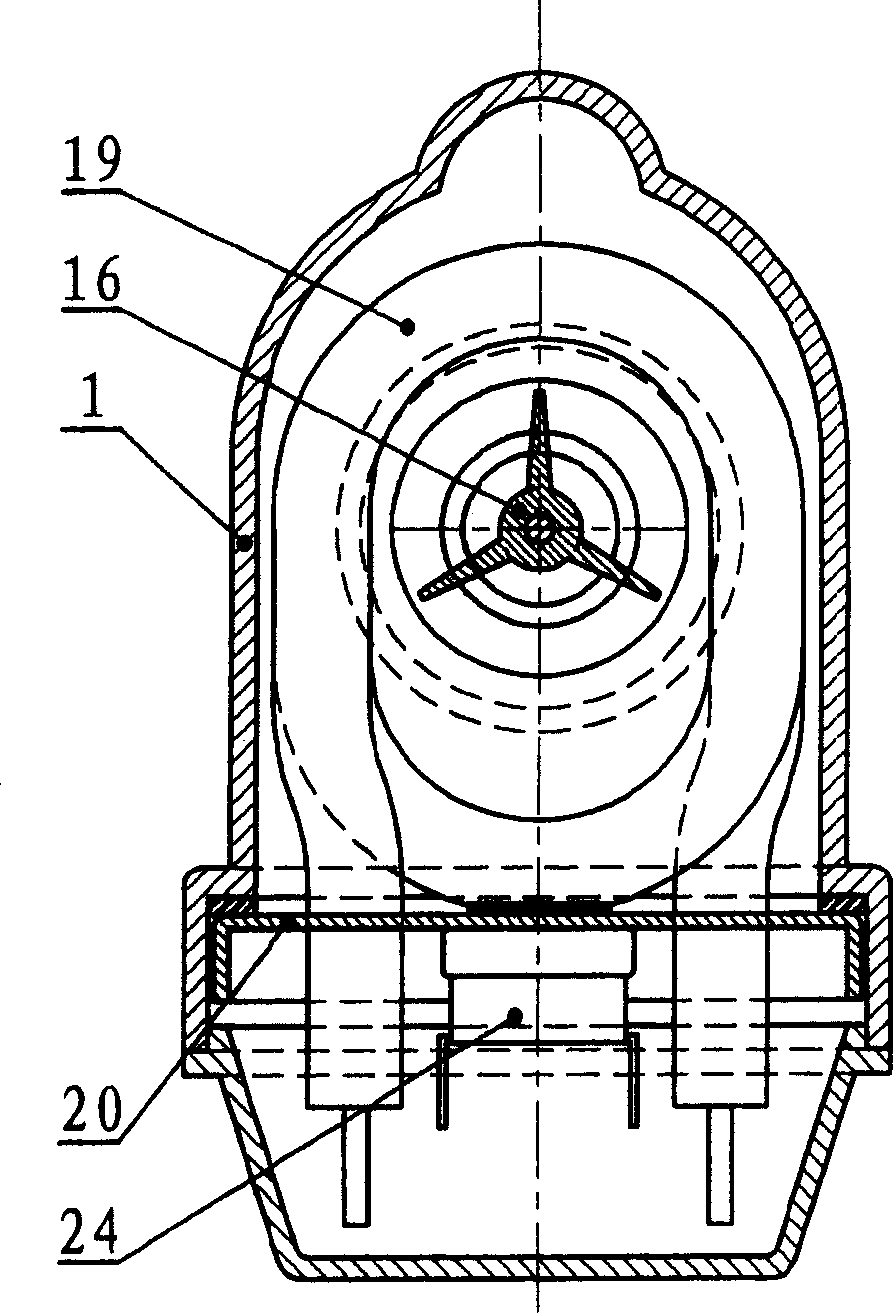

[0028] Depend on figure 1 , figure 2 , image 3 It can be seen that the main structure of the device of the present invention is a closed chamber, which communicates with the outside only through the inlet (18) and outlet (2) on it, and the chamber is divided into a smaller rotor chamber (6) and a larger heating chamber (3) Two parts, the two parts communicate through the rotor cavity, and the positional relationship between them is that the rotor cavity is on a side wall of the heating cavity (3), and the rotor cavity (6) protrudes outward from the rotor cavity Outside the heating chamber (3). Such a positional relationship shows that the rotor cavity opening is the interface between the rotor cavity (6) and the heating cavity (3). After the front bearing (5) is installed on the rotor cavity opening, the front bearing (5) connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com