Non-reciprocal circuit element

A technology for circuit components and components, applied in the field of non-reciprocal circuit components, can solve the problems of poor performance, troublesome assembly operations, and poor productivity, and achieve the effects of small position shift, good assembly, and good productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

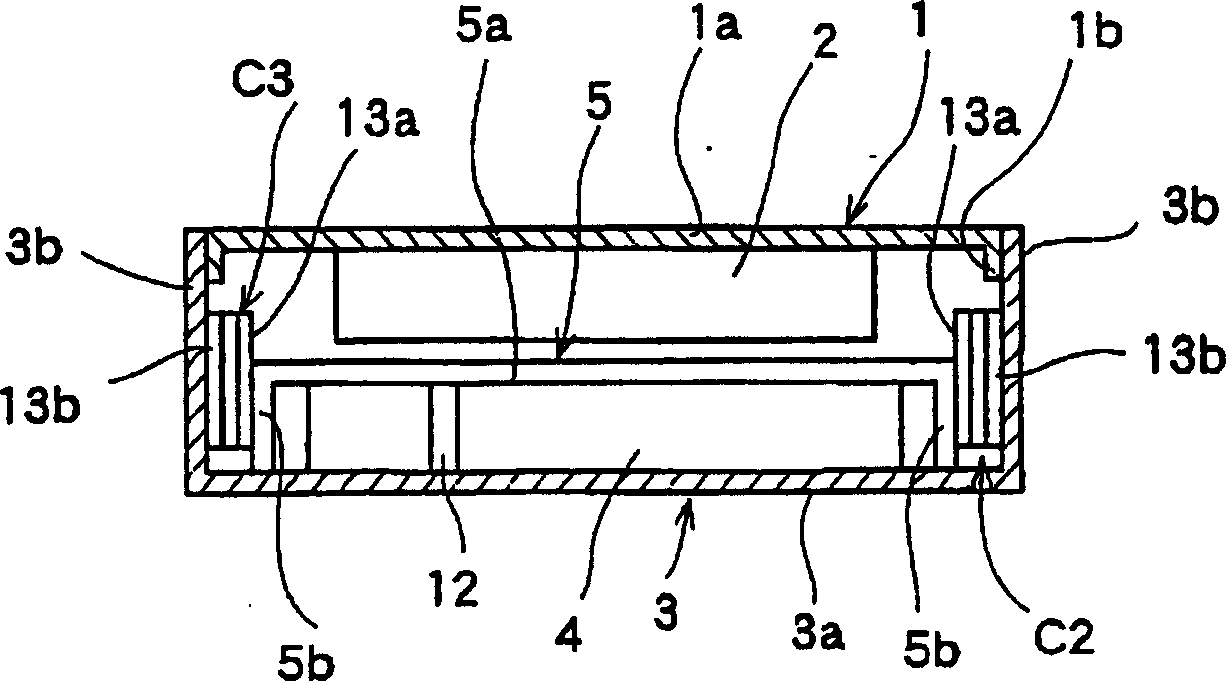

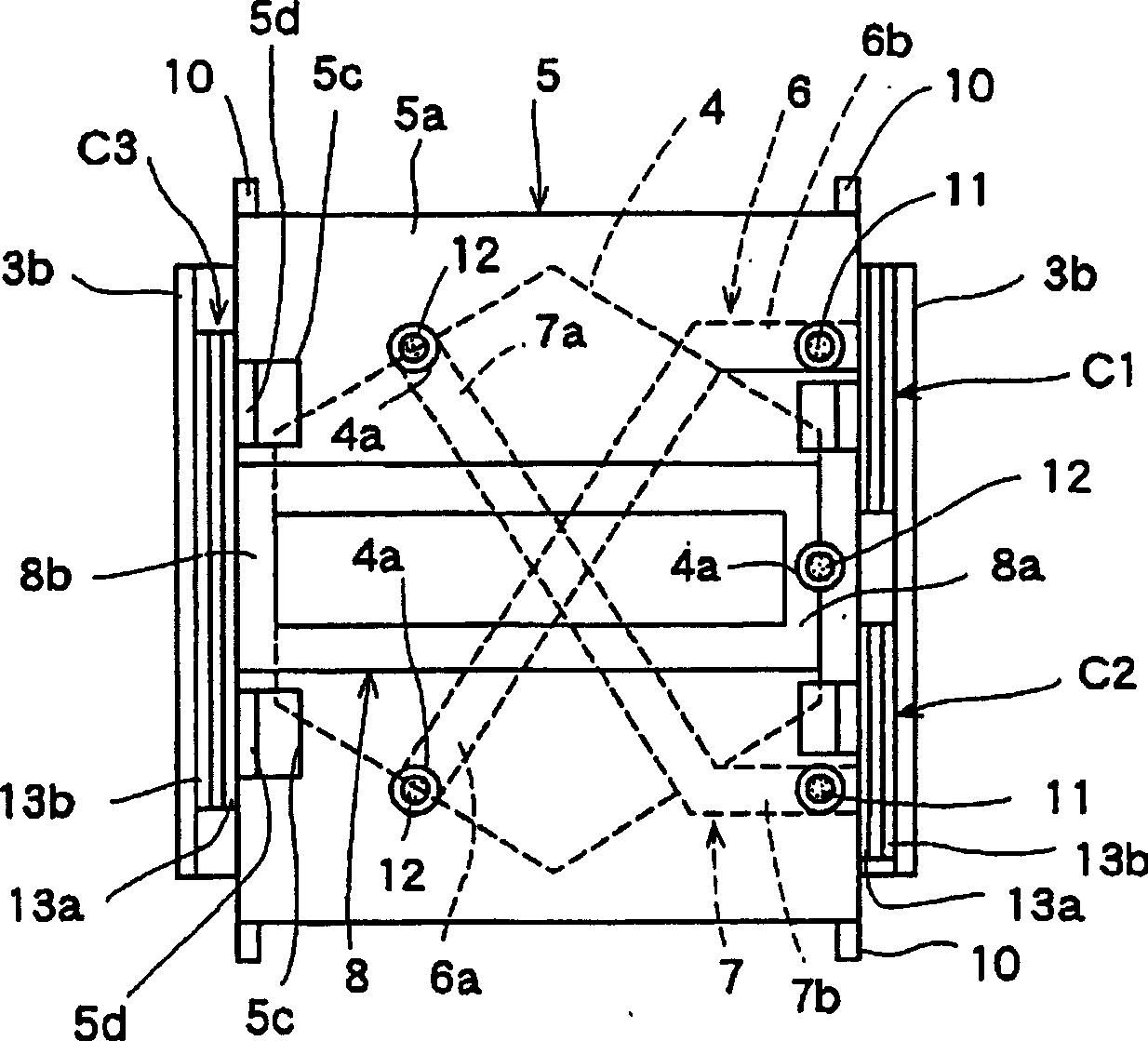

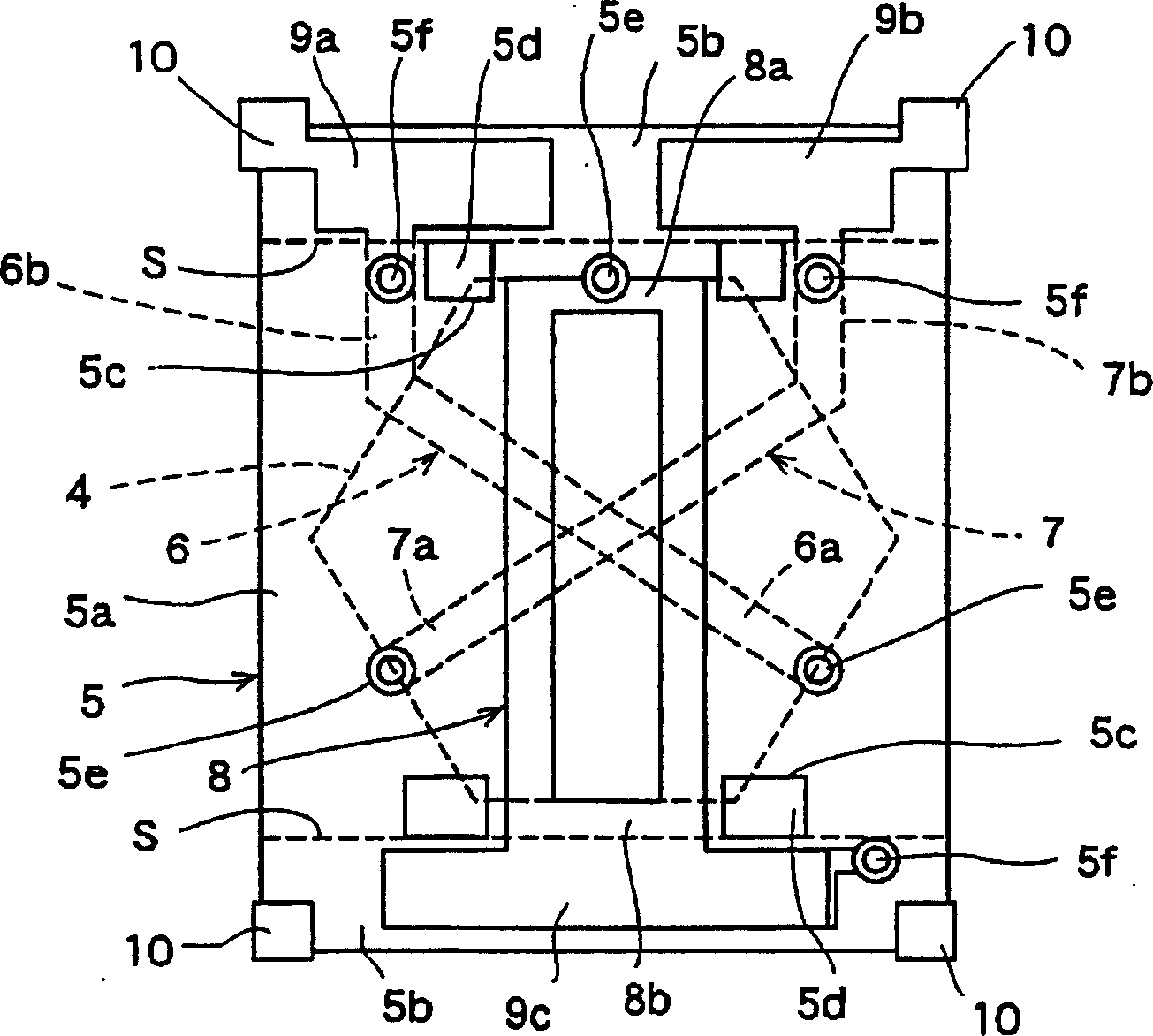

[0046] First, the drawings illustrating the nonreciprocal circuit element of the present invention, figure 1 It is a sectional view of main parts of the nonreciprocal circuit element of the present invention, figure 2 It is a plan view showing a state in which the first yoke and the magnet of the nonreciprocal circuit element of the present invention are removed, image 3 It is a developed view showing the dielectric body of the nonreciprocal circuit element of the present invention, Figure 4 It is a developed view of a state in which a capacitor is mounted on a dielectric body of the nonreciprocal circuit element of the present invention, Figure 5 It is a perspective view of the dielectric body of the nonreciprocal circuit element of this invention.

[0047] Below, refer to Figure 1 to Figure 5 , to describe the structure when the nonreciprocal circuit element of the present invention is used in an isolator, a U-shaped first yoke 1 composed of a box-shaped magnetic pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com