Method and equipment for processing organic material

A technology for organic raw materials and equipment, applied in the field of processing organic raw materials, can solve the problems of extreme sensitivity to temperature changes, inability to store, high carbon dioxide content, and achieve the effects of reducing pH changes, facilitating storage and stabilizing the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

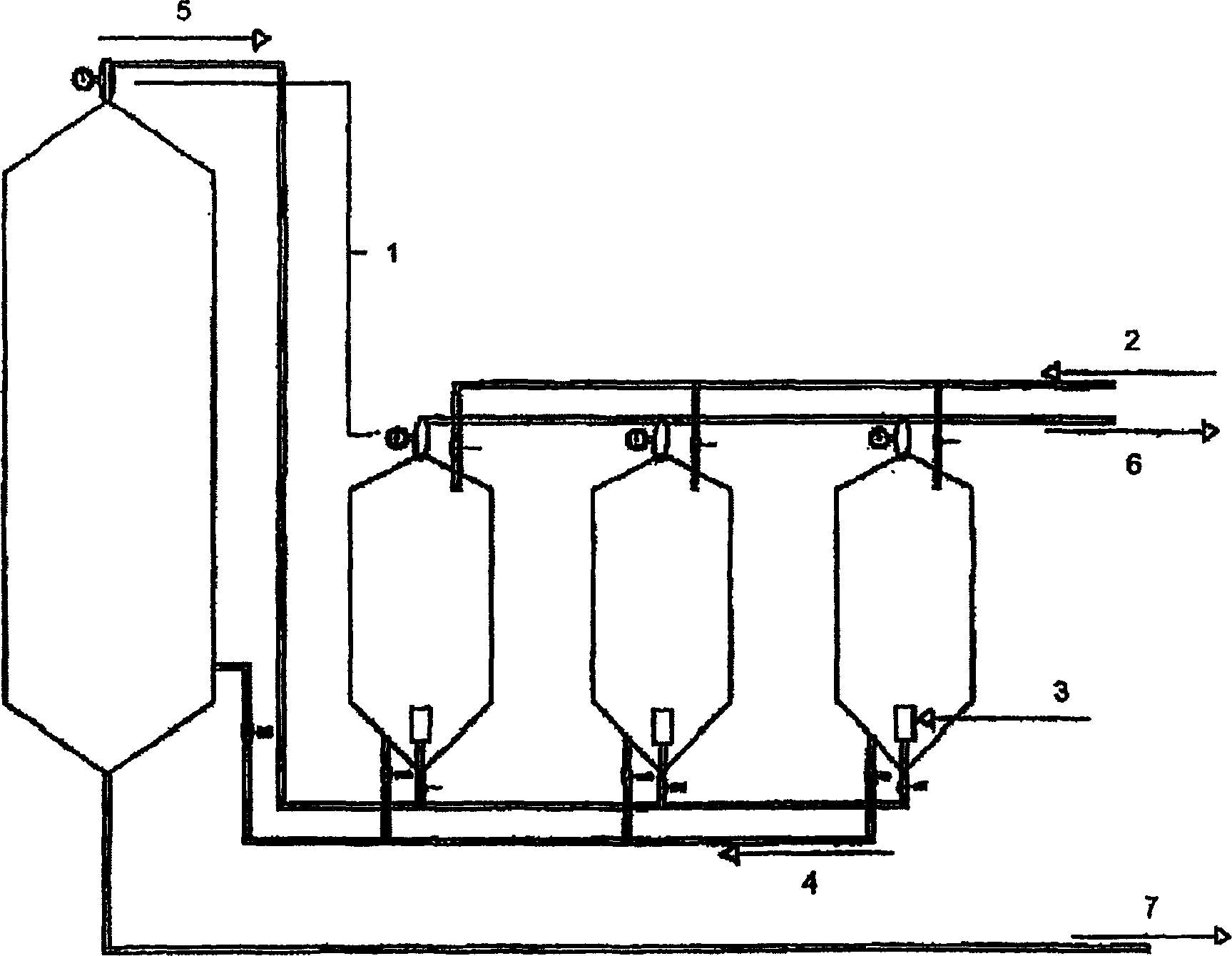

[0059] Treatment of organic raw materials and generation of biogas

[0060] Into the reactor R1 with a capacity of 300 liters, the organic material and 20 liters of inoculum containing 18.8 kg of bone meal, 28.9 kg of fish and 3.8 kg of genetically manipulated yeast ( Genencor). The pressure in the reactor was 2 bar. The pH in the reactor was 8.2. Determination of total NH with a spectrophotometer 4 The content is 9200mg / l. In addition, the amount of carbonate was measured using sulfuric acid, from which the ammonium ion content was calculated as the amount of ammonium carbonate. The ammonium ion content was calculated to be 8700 mg / l and the carbonate content was 46300 mg / l. Alkalinity and phosphate content were also determined. The alkalinity is 32000 and the phosphate content is 1200mg / l. The quantity and composition of the biogas obtained from the reactor were measured. On the second day, the reactor produced 109.4 L / day of biogas containing 74.6% CH 4 and 20.0% C...

Embodiment 2

[0063] Treatment of organic raw materials and generation of biogas

[0064] Into a reactor R4 with a capacity of 250 liters, an organic material containing 6.2 kg of bone meal, 24.15 kg of fish and 3.92 kg of genetically manipulated yeast (Genencor ). The pressure in the reactor was 2 bar. The pH in the reactor was 8.0. Determination of total NH with a spectrophotometer 4 The content is 5800mg / l. In addition, the amount of carbonate was measured using sulfuric acid, from which the ammonium ion content was calculated as the amount of ammonium carbonate. The ammonium ion content was calculated to be 7400 mg / l and the carbonate content was 39400 mg / l. Alkalinity and phosphate content were also determined. The alkalinity is 21000 and the phosphate content is 1100mg / l. The quantity and composition of the biogas obtained from the reactor were measured. On the second day, the reactor produced 140 L / day of biogas containing 76.8% CH 4 and 17.4% CO 2 .

Embodiment 3

[0066] Validation of Buffering Properties of Organic Feedstock in Reactors Using Sulfuric Acid Addition

[0067] A 50 ml sample of organic feedstock was withdrawn from reactor R(4) during processing. To verify the buffering properties, the pH of the sample was measured, after which 1-% H 2 SO 4 . The pH of the sample was 7.6 before acid addition.

[0068] 1-%H 2 SO 4 Adding amount, ml

[0069] Distilled water has a pH of 7.6. Add 0.5 ml of 1-% H to 50 ml of distilled water 2 SO 4 , whereby its pH drops to 2.3. The buffering effect is thus clearly visible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com