A longtidunal micrometric separator for classifying solid particulate materials

A technology for solid particles and granular materials, which is used in solid separation, separation of solids from solids by air flow, classification, etc. It can solve the problems of the separator being easily worn, the structure is complex, and the materials that will block the classification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

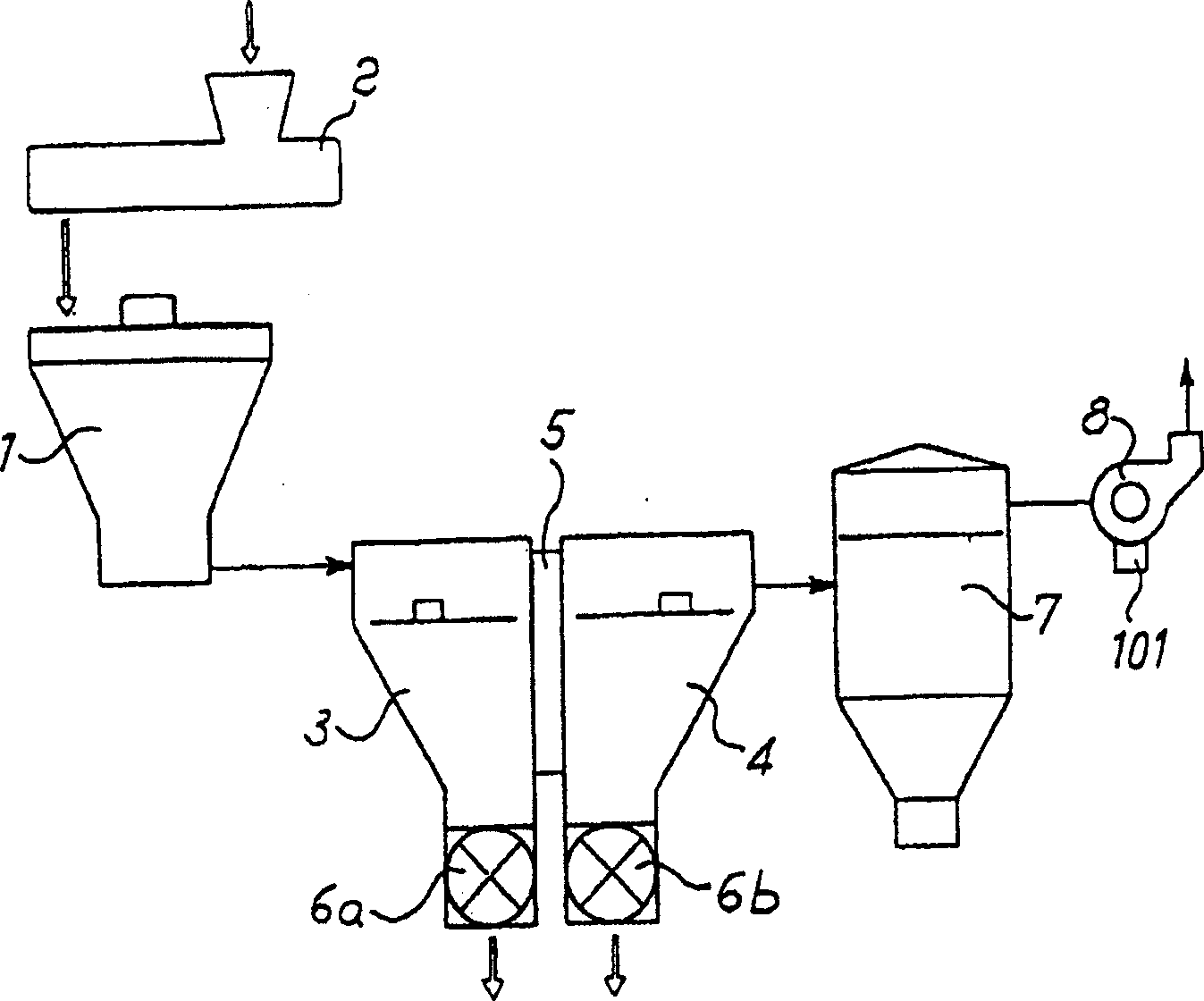

[0029] see first figure 1 According to a preferred aspect of the present invention, the solid particle material separation system includes a superfine pulverizer 1 fed by a screw conveyor 2, two separators 3 for classification that are arranged downstream of the superfine pulverizer 1 and are connected in series , 4, the filtering device 7 and the suction device 8 connected to the outflow pipe of the separator 3,4.

[0030] The two separators 3, 4 are in fluid communication with each other by means of a connector 5, and each separator has, at its bottom part, a rotary discharge valve 6a, 6b, for example in the shape of a star. The suction device 8 is also designed to generate a forced flow of air during the suction and can be equipped with a device 101 for regulating the generated air flow.

[0031] Thus, the material to be classified is conveyed by means of a screw feed conveyor 2 to an attritor 1 in which said material is ground until it assumes the form of particulate matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com