Method and equipment for automatic production of macromolecule wear-proof sliding-proof sole

A polymer and equipment technology, applied in the field of automatic production of polymer wear-resistant and anti-skid soles, can solve the problems of many wastes in corners, low labor productivity, affecting the health of labor producers, etc., and achieves time-saving, novel and unique structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

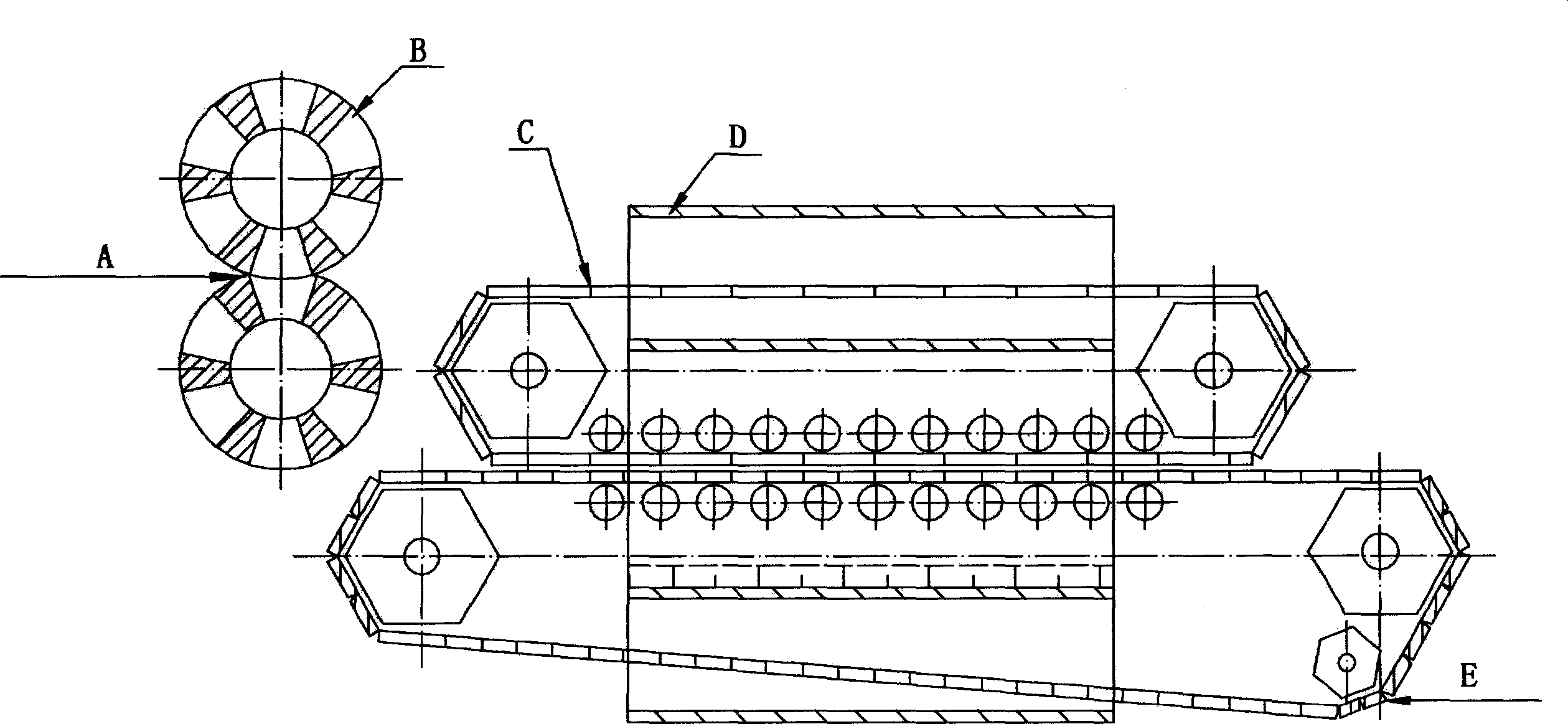

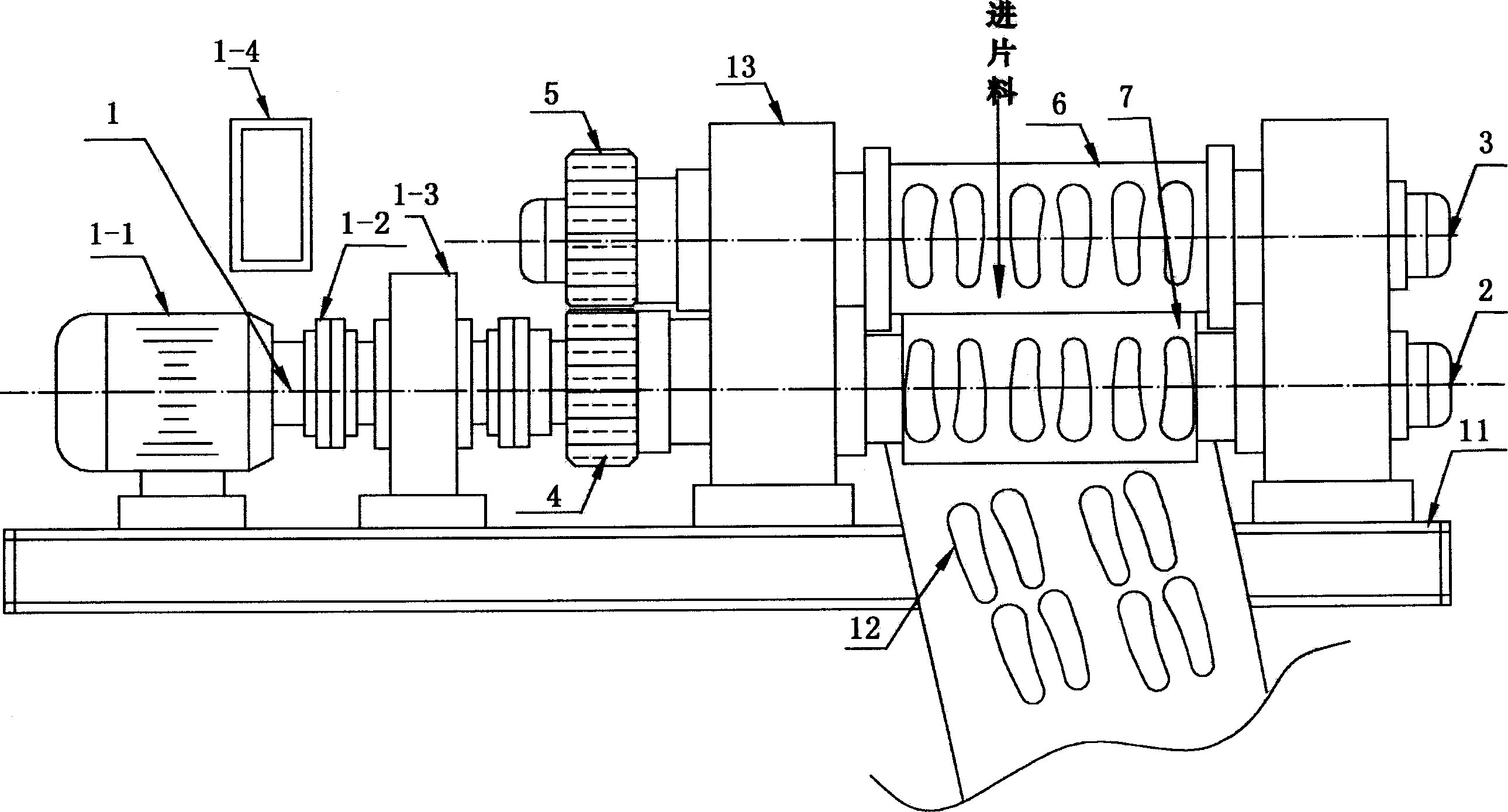

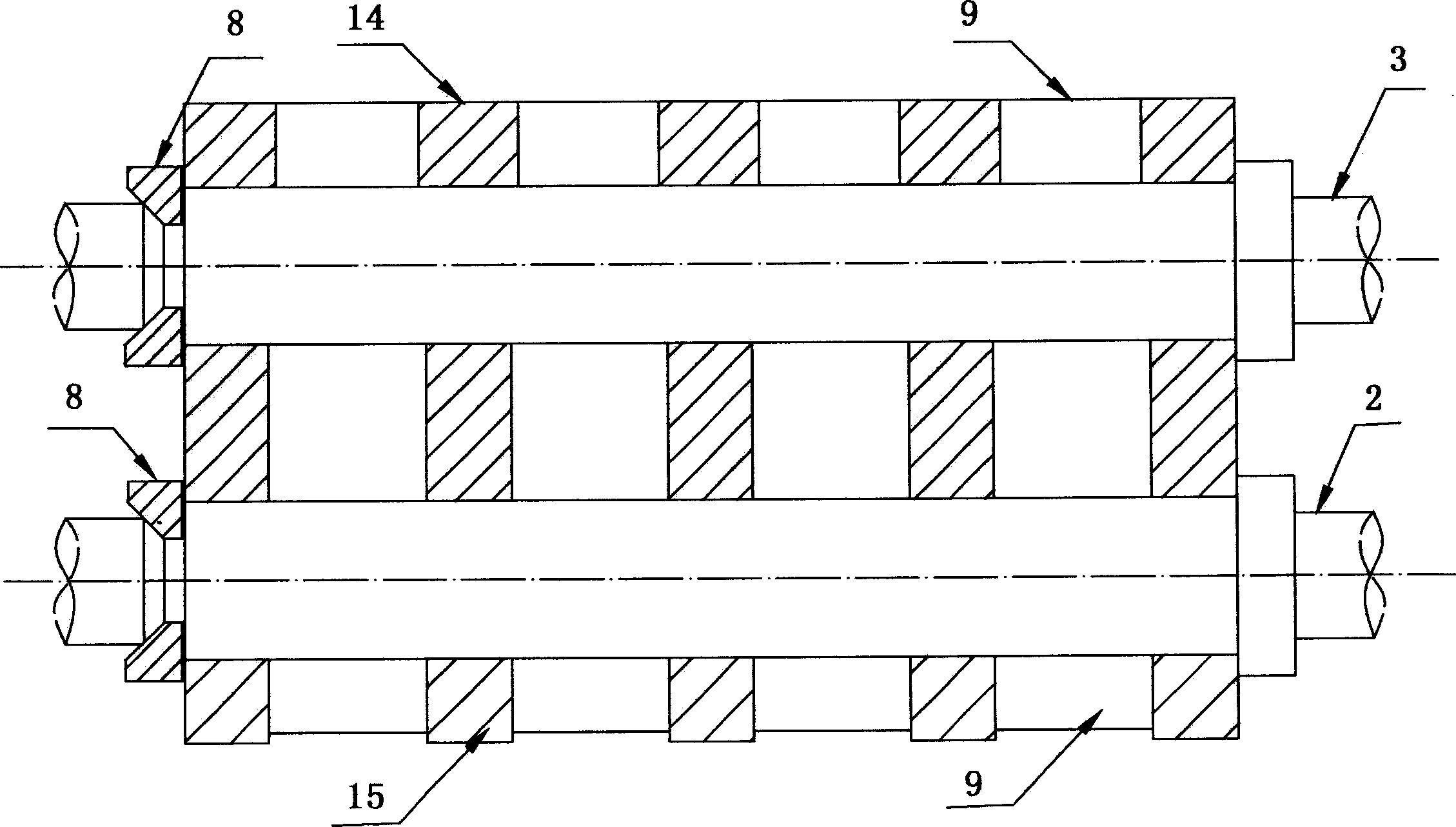

[0048] The formula of Example 1 in Table 1 is mixed and rolled into a semi-vulcanized rubber sheet in an ordinary open mill A, and the rolling temperature is about 50-60 °C, and enters such figure 2 In the drum-type sole blank machine B, the frequency conversion speed regulation motor 1-1 is started through the electric control cabinet 1-4, and the frequency conversion speed regulation motor drives the coupling 1-2, and drives the transmission lower gear after being decelerated by the reducer 1-3 4. The transmission lower gear 4 drives the transmission upper gear 5. The transmission lower gear is assembled and locked on the mold roller drive shaft 2, and the transmission upper gear is assembled and locked on the mold roller driven shaft 3. Therefore, the transmission lower gear and the upper transmission The simultaneous rotation of the gear also drives the simultaneous rotation of the main shaft of the molding roller and the driven shaft of the molding roller. The upper moldi...

Embodiment 2-3

[0053] The step of embodiment 2-3 is identical with embodiment 1 with equipment, and difference is the production process parameter situation of leather sole material, as listed in example 2-3 in the table.

[0054] example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com