Process for producing biodegradable fiber molding

A technology of biodegradability and manufacturing method, which is applied in the field of manufacturing biodegradable fiber material moldings, can solve problems such as inability to biodegrade, and achieve the effect of low water content and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

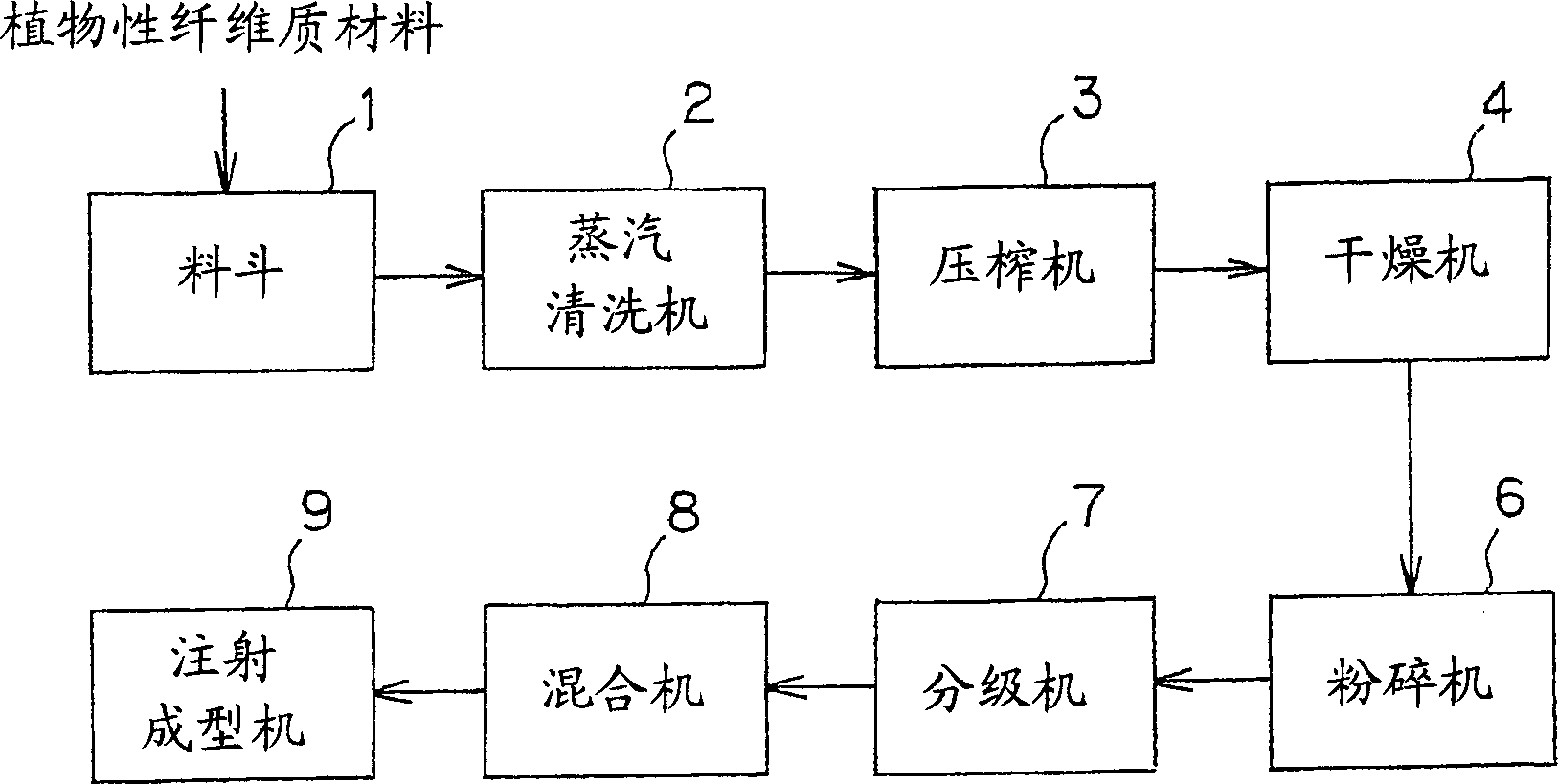

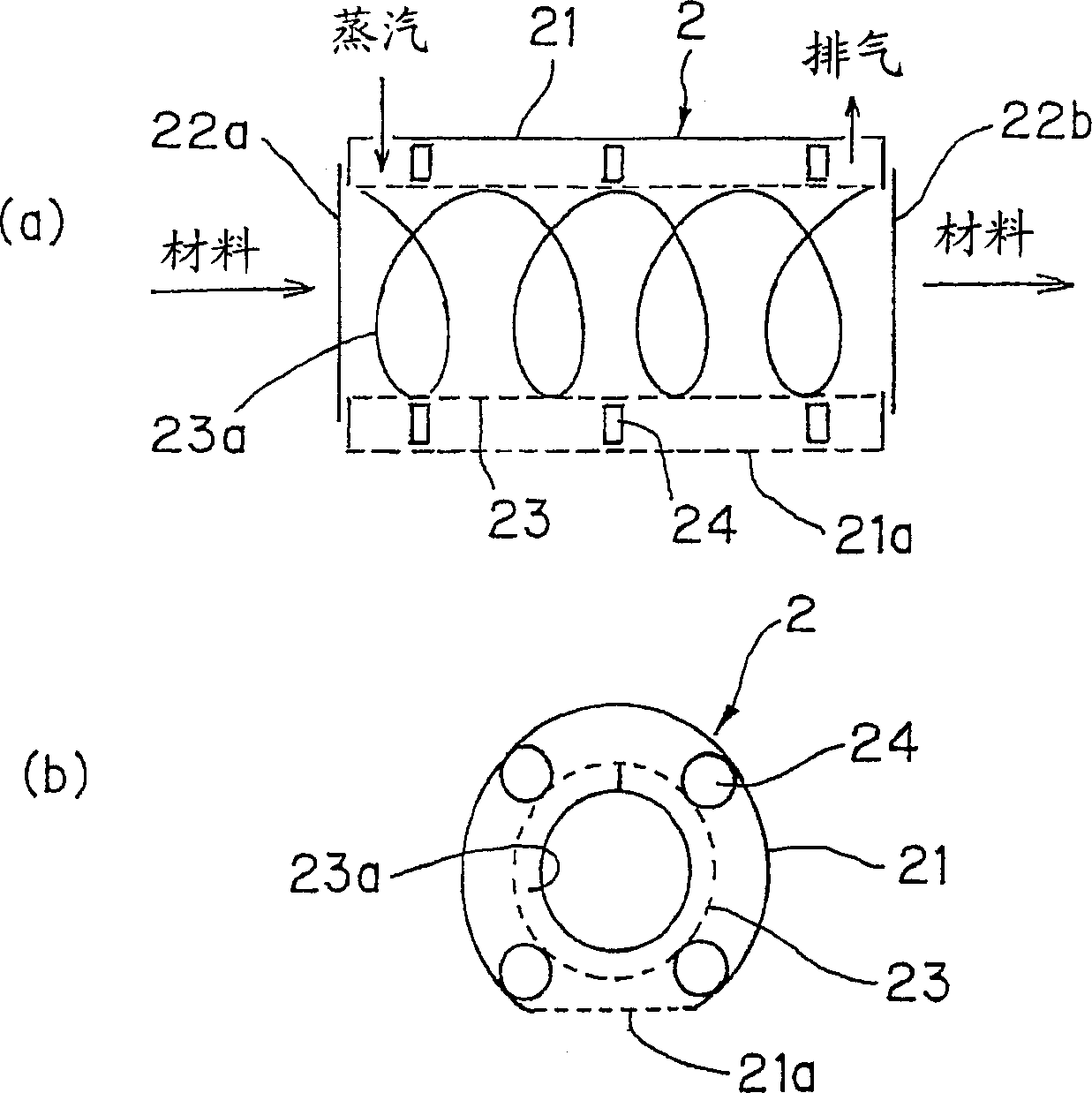

Method used

Image

Examples

Embodiment 1

[0099] Embodiment 1: Manufacture spherical shaped body

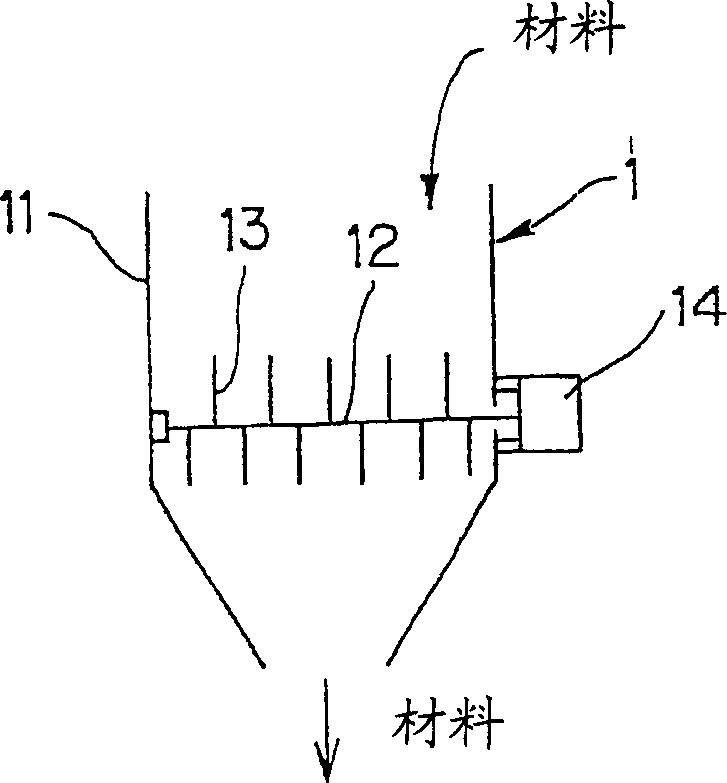

[0100] Using the device from the hopper 1 to the classifier 7, the thinned wood of cedar is used to prepare a vegetable fiber material powder with a particle size of 60-200 mesh and a moisture content of 8% by weight. Evenly mix 58 parts by weight of the vegetable fiber material powder and 17 parts by weight of the vegetable binder powder to prepare a mixed powder, add 25 parts by weight of water to the mixed powder evenly for humidification, and use a mixer 8 A molded body raw material was obtained. As the vegetable binder powder, a mixture of 97% by weight of cornstarch, 2% by weight of xanthan gum, and 1% by weight of tamarind gum was used.

[0101] After putting the above-mentioned molded body raw materials into the injection cylinder from the raw material hopper of the injection molding machine, the molded body raw materials were extruded into a mold according to a conventional method to make a spherical molded bod...

Embodiment 2

[0103] Example 2: Making a Soup Bowl

[0104] Using the device from the hopper 1 to the classifier 7, bamboo is used to prepare a vegetable fiber material powder with a particle size of 60-200 mesh and a moisture content of 5% by weight. 63 parts by weight of the powder and 20 parts by weight of the vegetable binder powder were uniformly mixed to prepare a mixed powder, and 17 parts by weight of water was uniformly added to the mixed powder for humidification, and a raw material for a molded body was obtained by a mixer 8 . As the vegetable binder powder, a mixture of 98% by weight of cornstarch and 2% by weight of xanthan gum was used.

[0105] After the above-mentioned molded body raw materials were dropped into the injection cylinder from the raw material hopper of the injection molding machine, the molded body raw materials were extruded into the mold according to a conventional method to make a soup bowl with a weight of 65 g. The injection pressure during molding was 83...

Embodiment 3

[0107] Example 3: Manufacture of pendant pendant (Pendanttoptop)

[0108] Using the device from the hopper 1 to the classifier 7, grass is used to prepare a vegetable fiber material powder with a particle size of 60-200 mesh and a moisture content of 7% by weight. Uniformly mix 73 parts by weight of the vegetable fiber material powder with 14 parts by weight of the vegetable binder powder to prepare a mixed powder, and uniformly add 13 parts by weight of water to the mixed powder for humidification, and use a mixer 8 to obtain a molding body raw materials. As the vegetable binder powder, a mixture of 98% by weight of potato starch, 1% by weight of xanthan gum, and 1% by weight of tamarind gum was used.

[0109] After putting the above-mentioned molding raw materials into the injection cylinder from the raw material hopper of the injection molding machine, extrude the molding raw materials into a star-shaped mold with 5 cavities according to the conventional method to make pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com