Planar light waveguide measuring apparatus for micro-displacement

A planar optical waveguide and measuring device technology, which is applied in the directions of measuring devices, using optical devices, and using optical devices to transmit sensing components, can solve the problems of limited use, high cost, complex structure, etc. Simple process, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

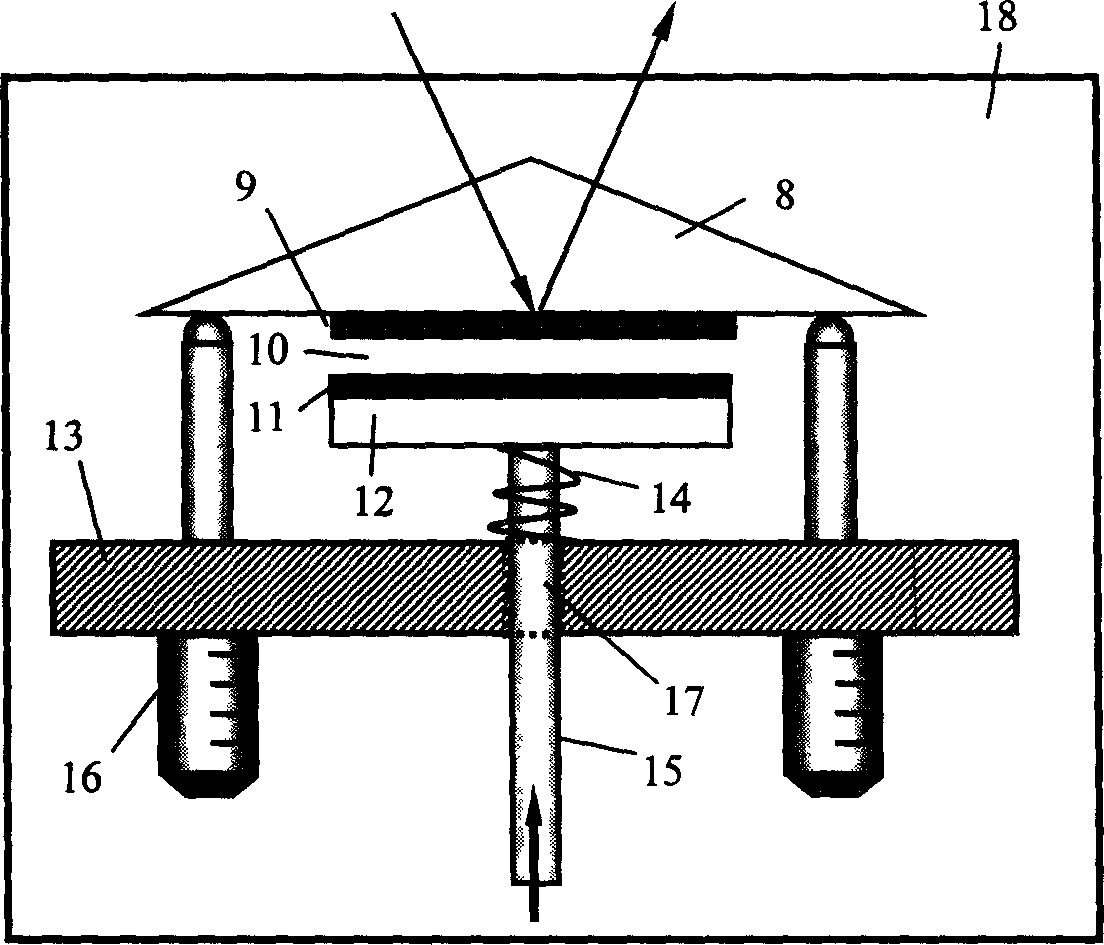

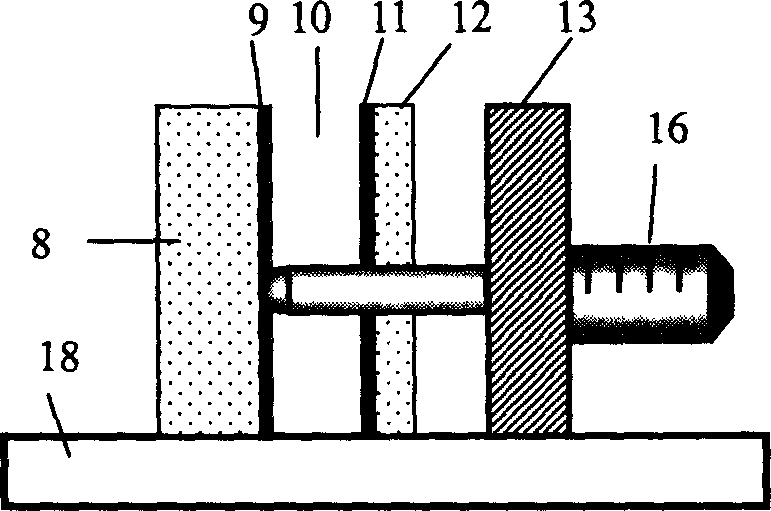

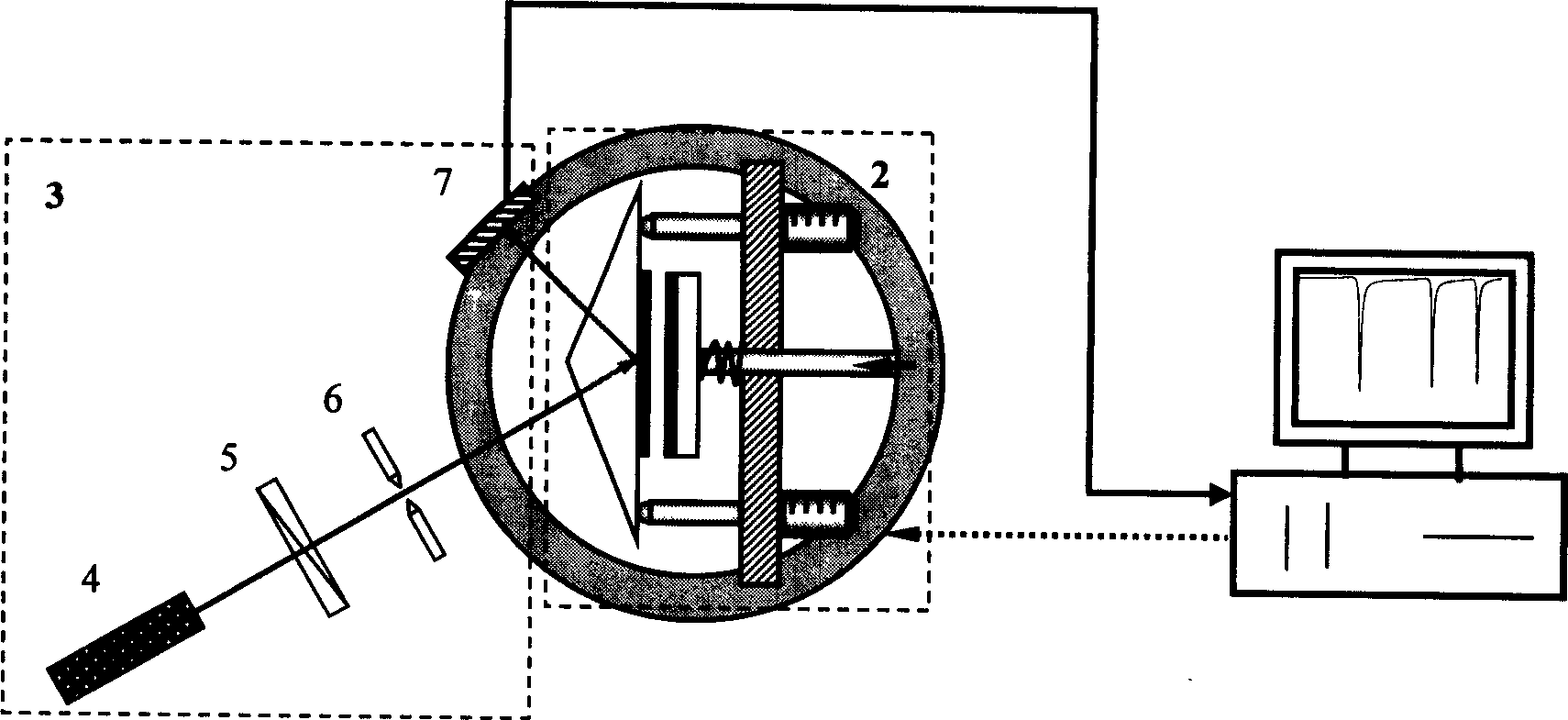

[0014] Such as Figure 1 to Figure 3 As shown, the device of the present invention is composed of an optical rotating platform 1, an optical waveguide micro-displacement sensor 2, and a photodetecting part 3. The optical waveguide micro-displacement sensor 2 is fixed on the optical rotating platform 1, and the optical rotating platform 1 supports the entire optical waveguide micro-displacement Sensor 2, photoelectric detection part 3 includes: laser 4, polarizer 5, optical aperture 6, photodetector 7, laser 4, polarizer 5, optical aperture 6 are fixed outside the optical rotating platform 1, and they maintain the same height. The optical axis points to the center of the optical waveguide micro-displacement sensor 2. The photodetector 7 and the laser 4 are symmetrical about the central axis of the optical waveguide micro-displacement sensor 2. At the same time, the photodetector 7 is fixed on the optical rotating platform 1, and the optical rotating platform 1 When the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com