Automatic refuse burning furnaces with multiple inclined verticle grates

A waste incinerator, multi-row technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of inability to increase the combustion speed, inability to change the angle of the furnace body, slow ignition of incinerated garbage, etc., and achieve long continuous operation time , Facilitate automatic operation, complete combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

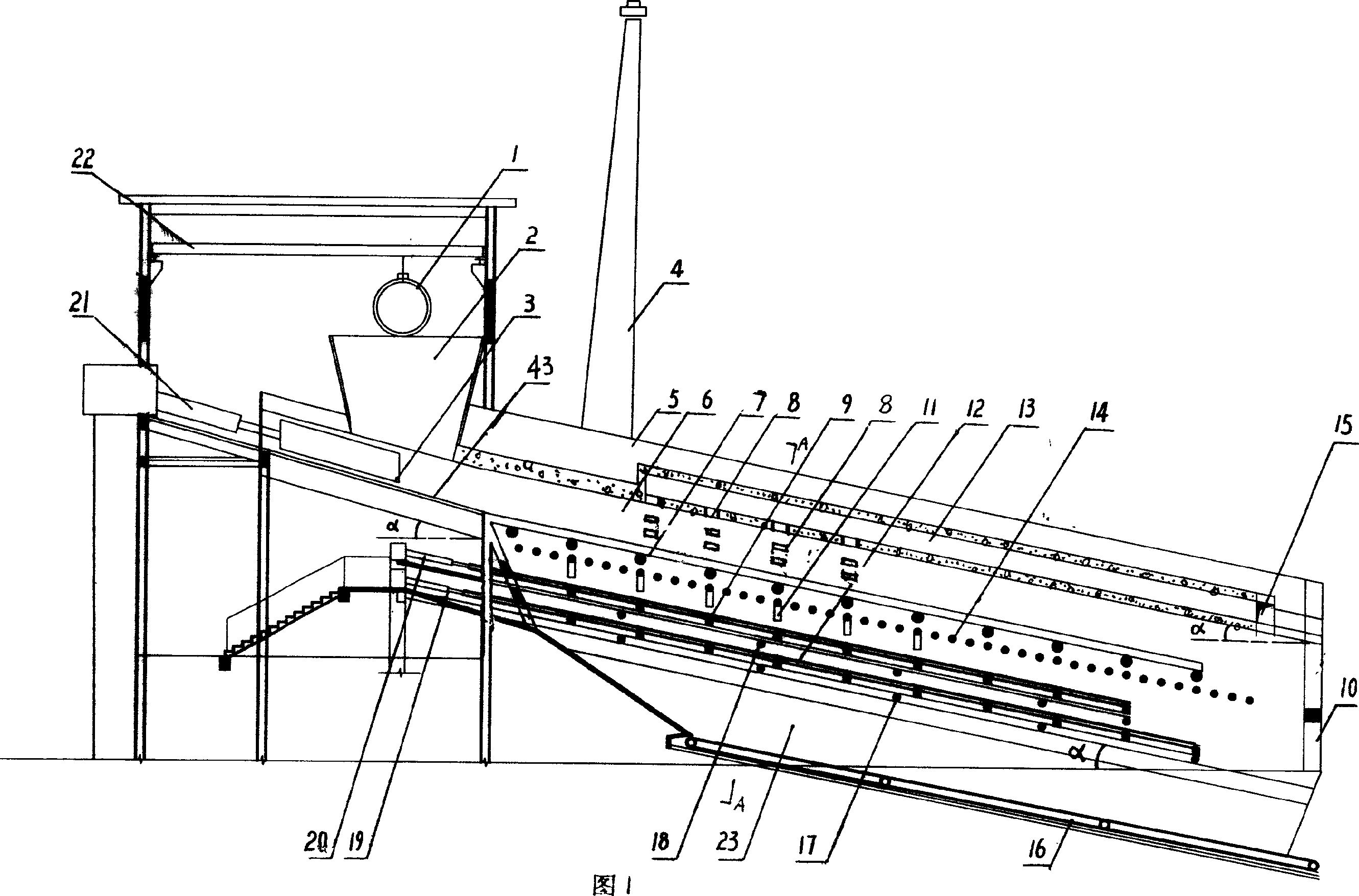

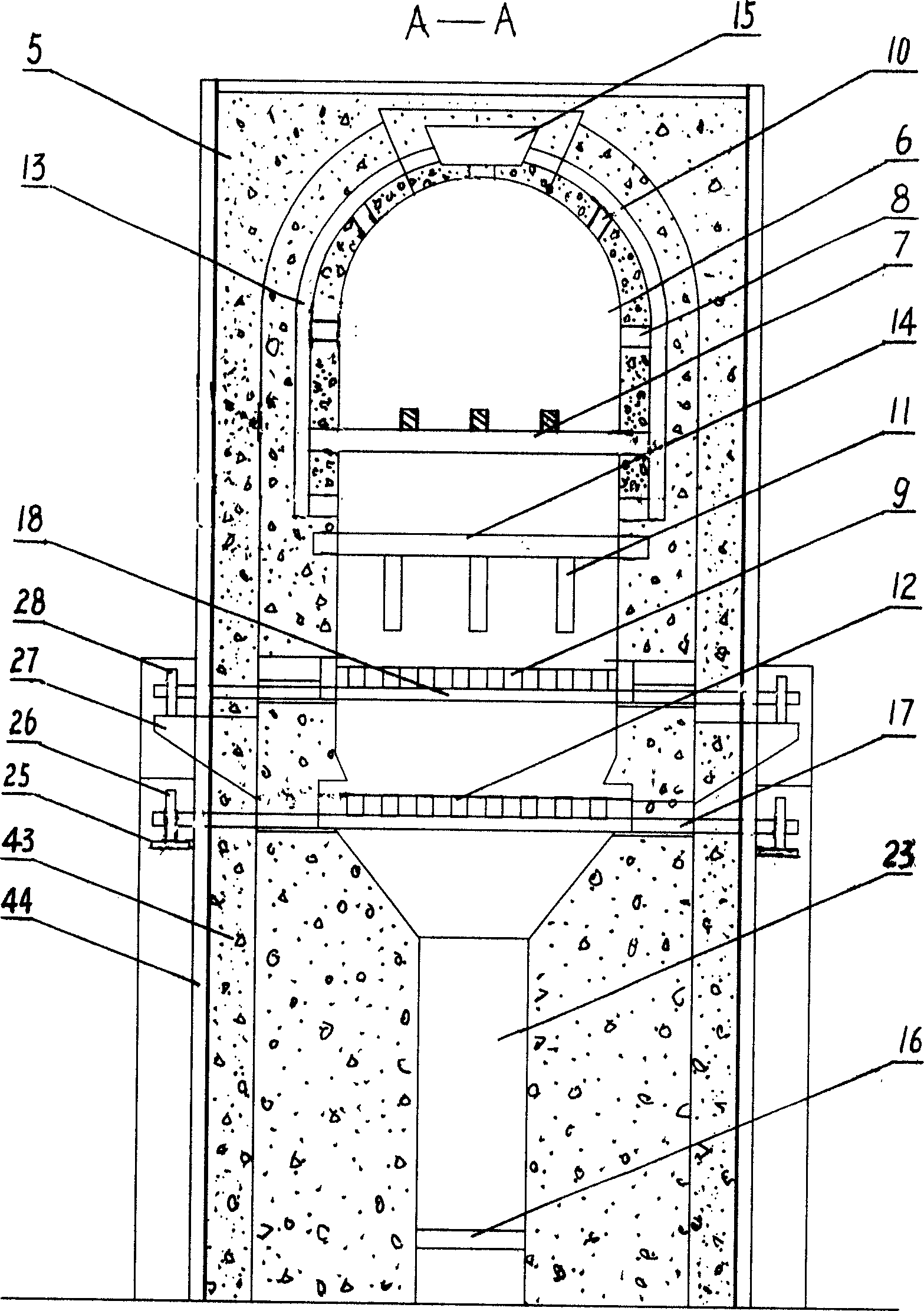

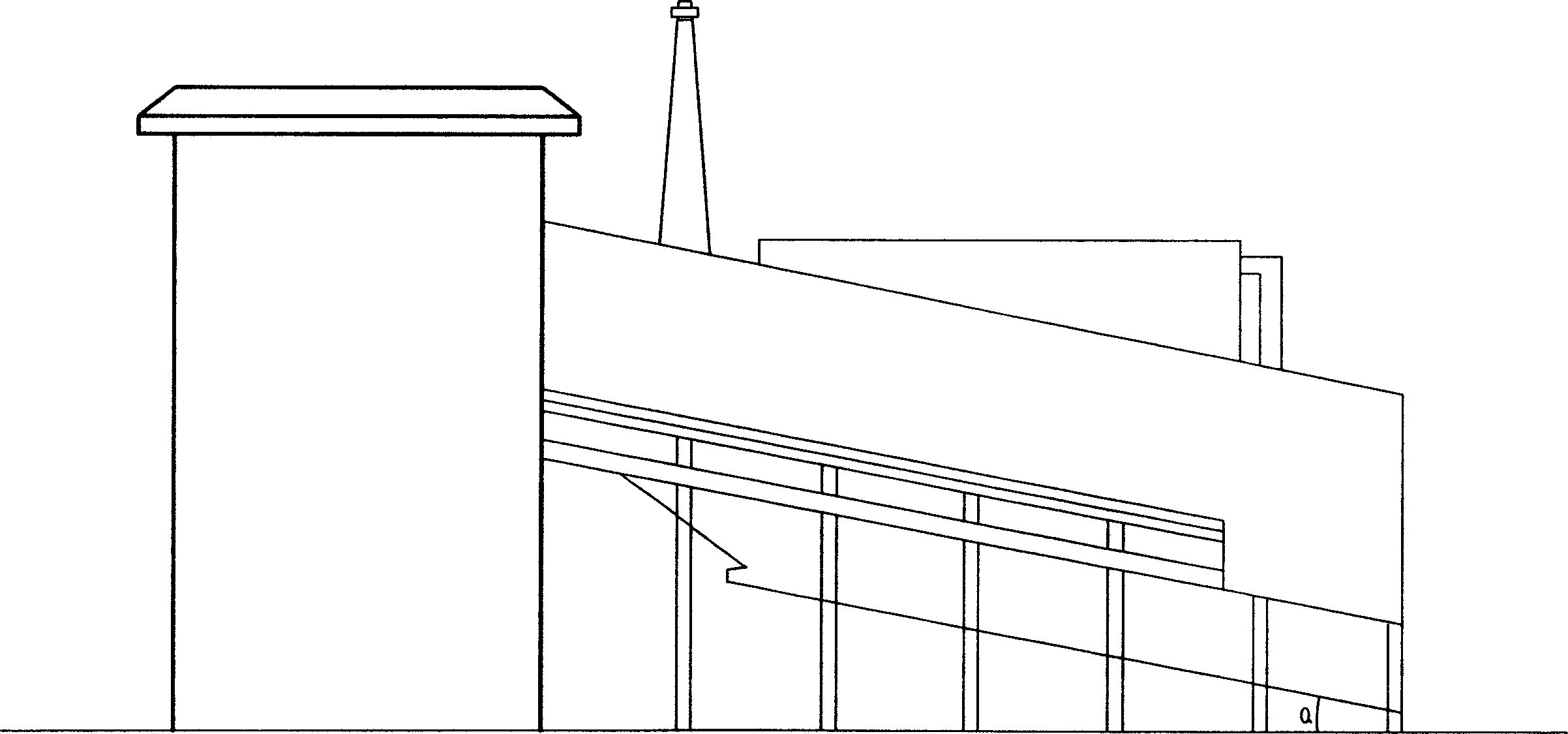

[0024] Embodiments of the present invention are as follows: As shown in the accompanying drawings: the present invention comprises a furnace body 5, a furnace 6, a fire grate arranged in the furnace 6, and a garbage inlet 2 and an ash outlet, and is characterized in that the furnace 6 and The fire grate arranged in the hearth 6 is arranged obliquely, and the angle α between it and the horizontal plane is 5°<α<50°, and the optimum value is 10°<α<30°. The upper end of the inclined vertical hearth 6 is provided with The lower end of the feed port 2 is provided with a lower ash channel 23 , and the lower end of the furnace 6 is provided with an air inlet 10 .

[0025] The present invention is provided with four layers of inclined vertical fire grates in the inclined vertical furnace, wherein the first layer of fire grate is the upper fixed fire grate 7; the second layer of fire grate is the lower fixed fire grate 14; the third layer is the upper movable fire grate Grate 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com