Preparation of polymer based carbon balls

A polymer and carbon sphere technology, which is applied in the field of polymer-based carbon sphere preparation, can solve the problems of difficult large-scale preparation, uneven particle size, and many surface defects, and achieve uniform and controllable particle size, easy large-scale preparation, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

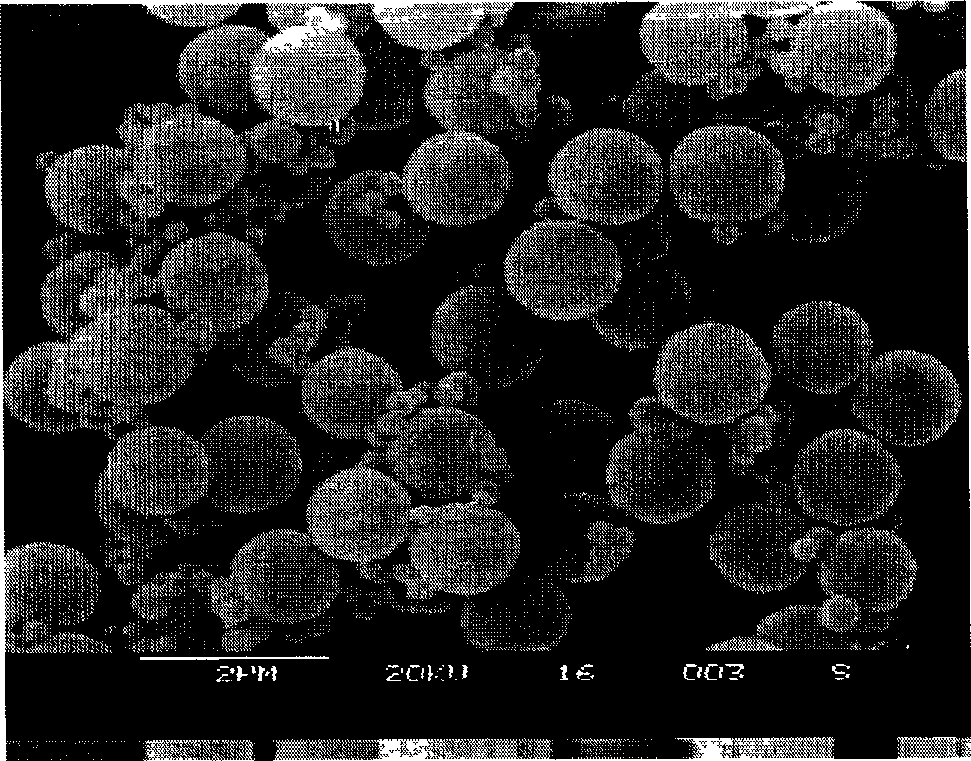

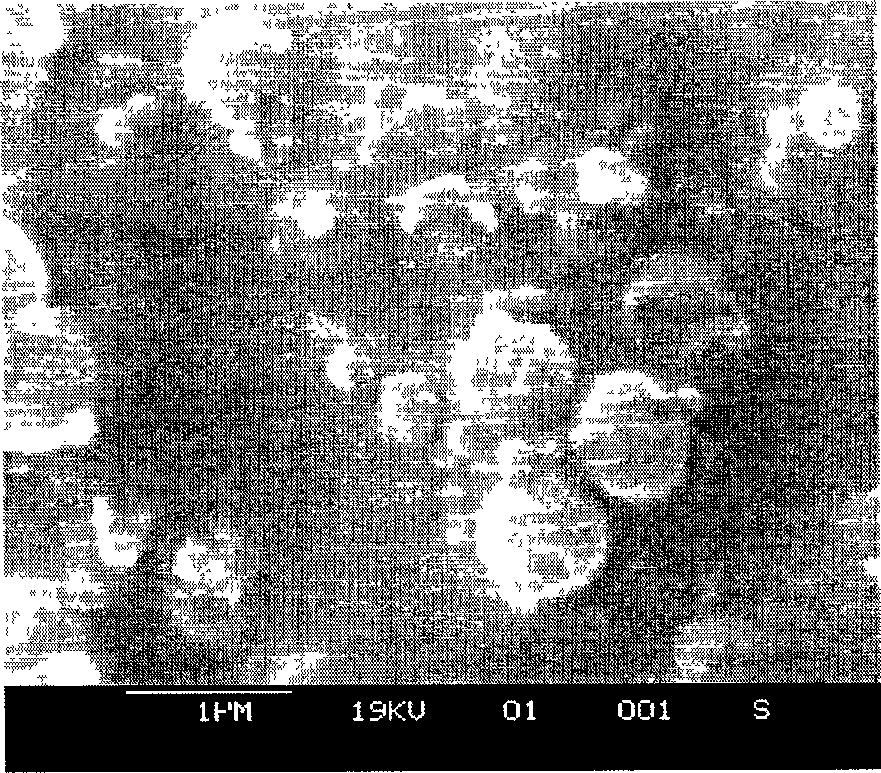

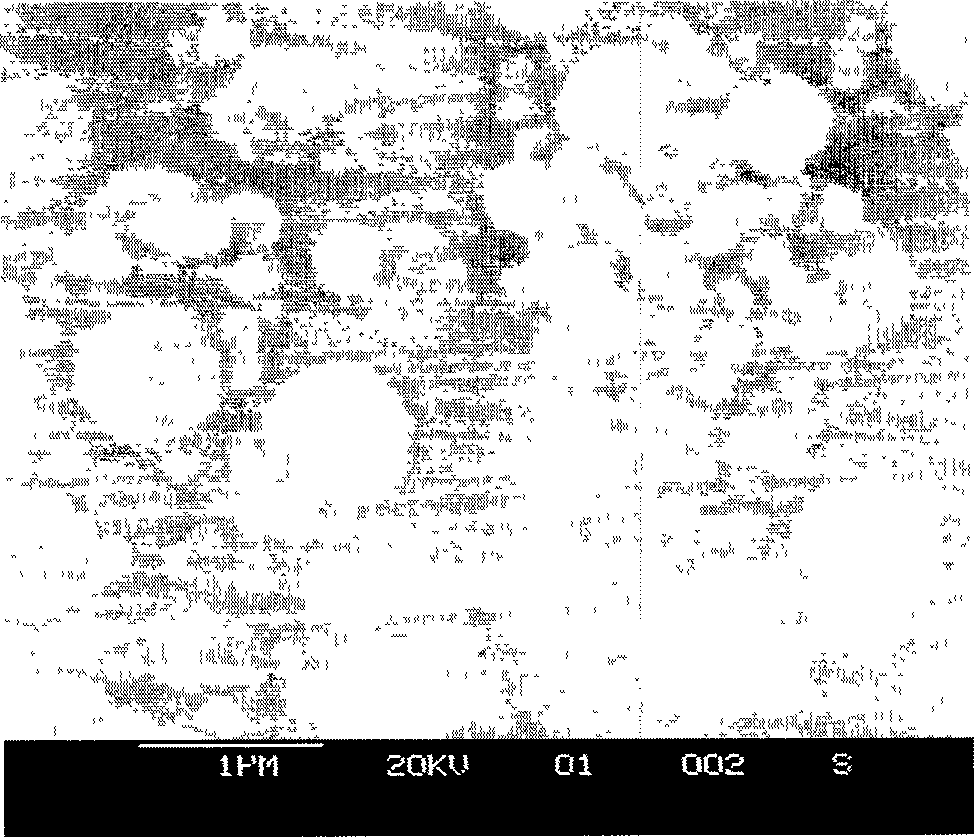

[0027] Take by weighing 10 grams of polyvinyl chloride (PVC) paste resin (commercially available, the model is P450, the degree of polymerization is: 1000 ± 150, the particle diameter is 300nm and 1.2 μ m bimodal distribution, scanning electron microscope photo sees figure 1 ) and 10 grams of KOH (analytically pure, molecular weight 56.10) were put into a three-necked flask, and then 100 grams of deionized water was added. The mass ratio of polyvinyl chloride paste resin, KOH and deionized water is 1:1:10. The three-neck flask was placed in a water bath and reacted at a constant temperature of 95° C. for 3 days under constant stirring. Then the reactants were taken out, washed with deionized water until neutral and dried at 100°C, and then placed in a blast oven at 240°C for air oxidation treatment for 1 hour. Put the treated polyvinyl chloride paste resin into a carbonization furnace to raise the temperature to 1000°C at a rate of 2°C / min., and stay at this temperature for o...

Embodiment 2

[0029] The operation method is the same as in Example 1, except that the temperature of the air oxidation treatment is 180° C., and the time is 3 hours. The morphology and particle size of the polymer-based carbonized carbon spheres are the same as in Example 1.

Embodiment 3

[0031] The operation method is the same as in Example 1, except that the mass ratio of polyvinyl chloride paste resin, KOH and deionized water is 1:17:10; the three-necked flask is placed in an electric heating mantle for heating; the temperature of the alkali treatment The temperature is 130°C; the alkali treatment time is 12 hours. After carbonization at 1000°C, polymer-based carbonized carbon spheres are obtained as spherical black carbon powder, and then graphitized at 2500°C to obtain polymer-based graphitized carbon spheres. The final product remains solid spherical, and XRD tests show that it is crystallized The degree increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com