Pneumatic tire and tire mold

A technology for pneumatic tires and tire molds, which is applied to tire treads/tread patterns, tire parts, tires, etc., and can solve problems such as inability to effectively suppress defects or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

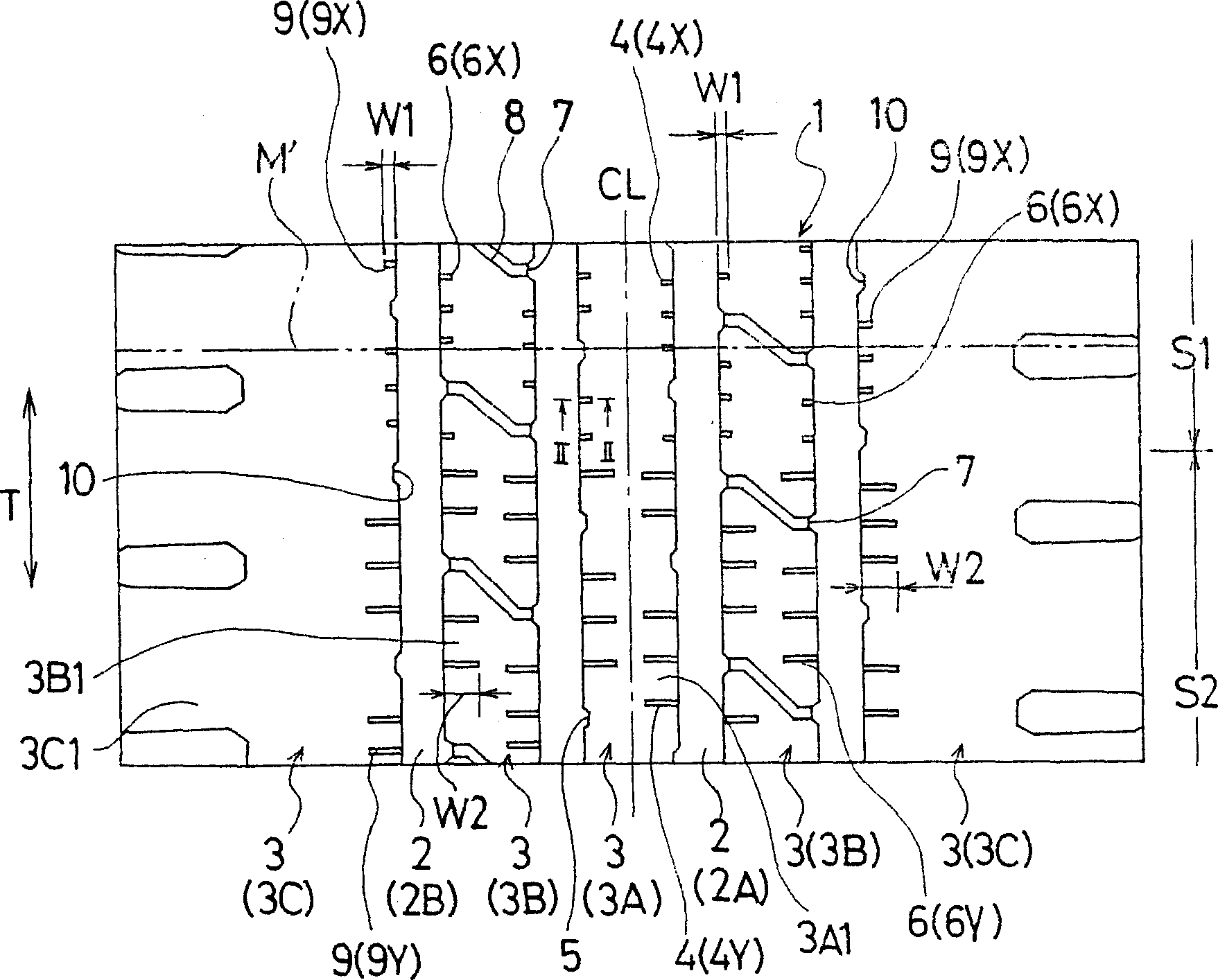

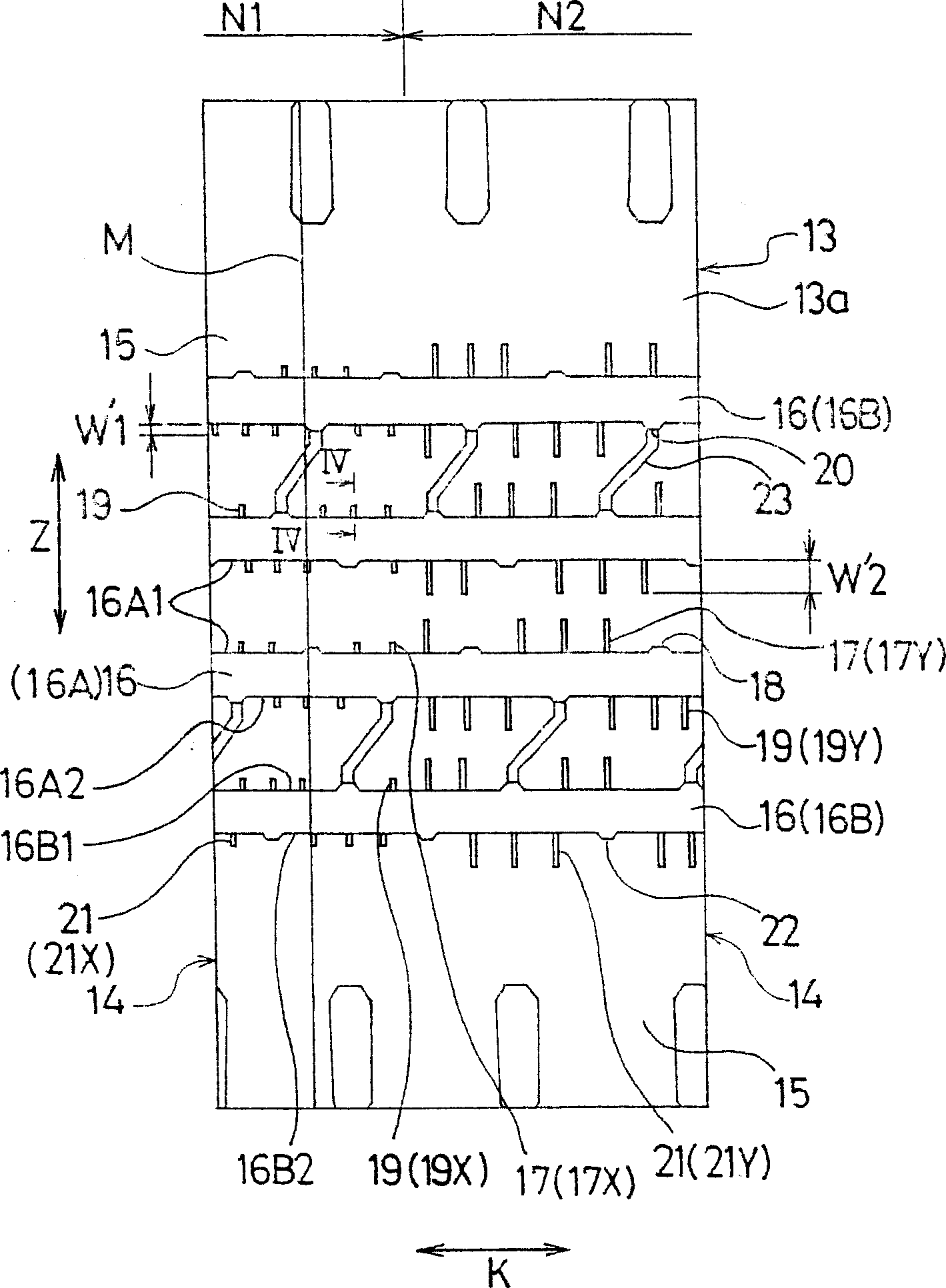

[0076] Assuming the same tire size as 145R12 6PR LT, the length in the tire width direction of the first sipe located in the first region S1 is shorter than that of the second sipe located in the second region S2 figure 1 In the tire 1 of the present invention having the structure shown, the opening end of the sipe located on the far side of the tread position M' where the distance of the first sipe coincides with the division position M of the sector is rounded. The shape of the edge of the first fine line on the far side of the tread position M' where the distance of the first fine line coincides with the division position M of the sector is rounded, Image 6 Ten tires of the present invention tire 2 having the structure shown and the conventional tires of the present invention tire 1 in which the tire width direction length of the fine lines were the same were taken, and vulcanized and molded using a split type tire mold.

[0077] In each of the test tires, a rubber having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com