Thermal pressure filtration process for deep dehydration of fine coal suspension liquid and apparatus therefor

A deep dehydration and suspension technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of high production costs, shrinking effective extrusion area, and affecting the use effect, etc., and achieve significant economic benefits. The effect of improving work efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

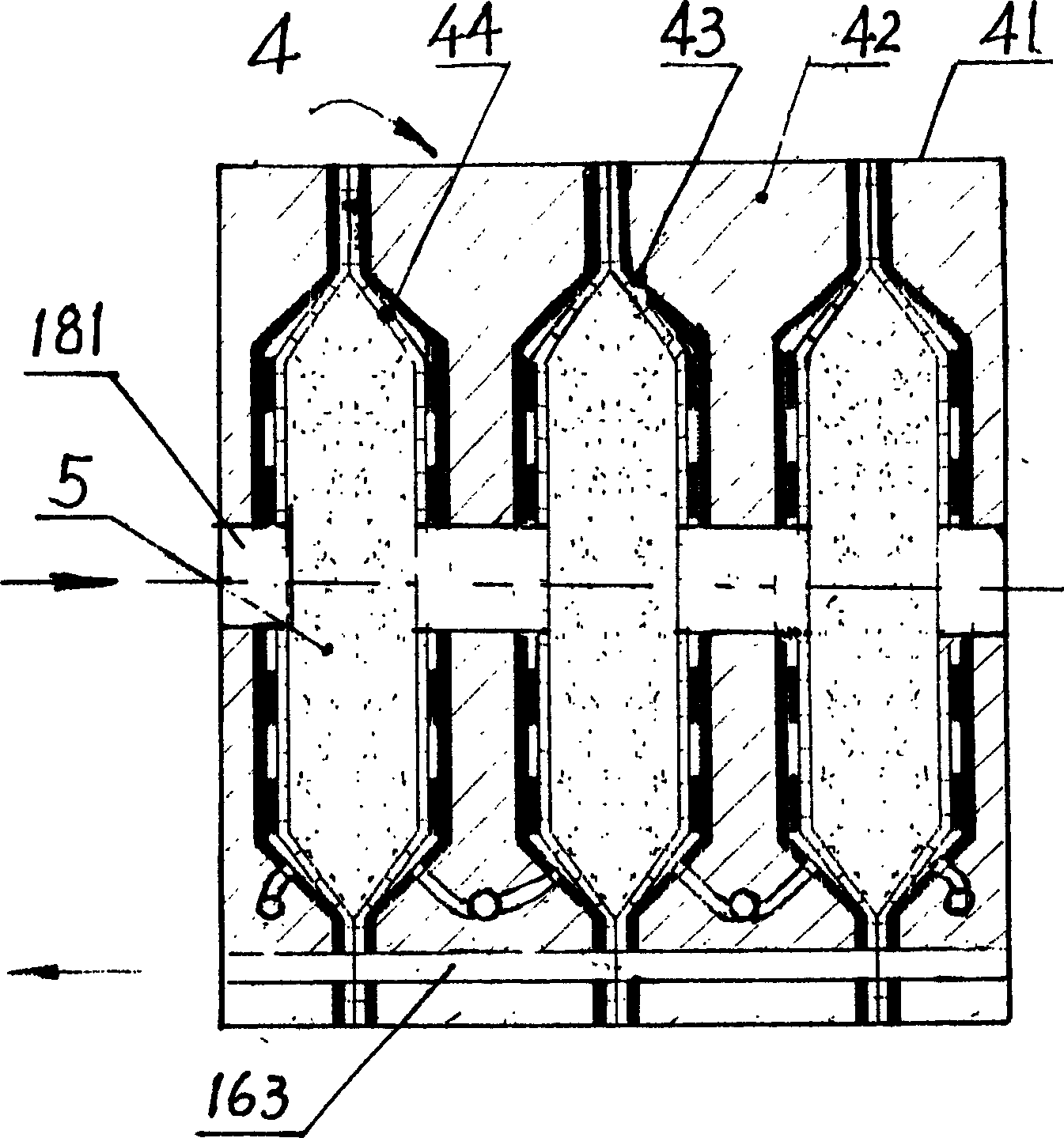

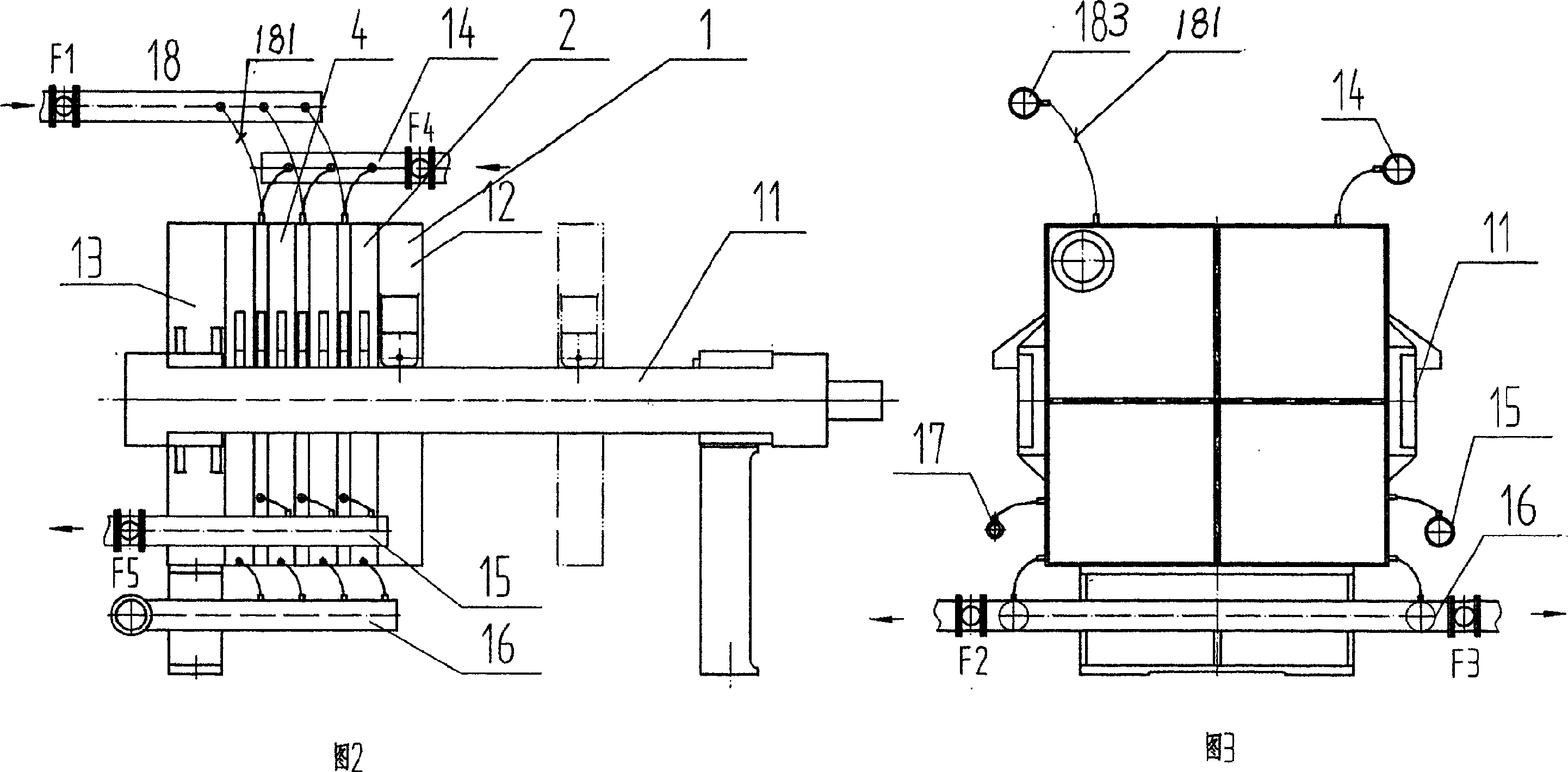

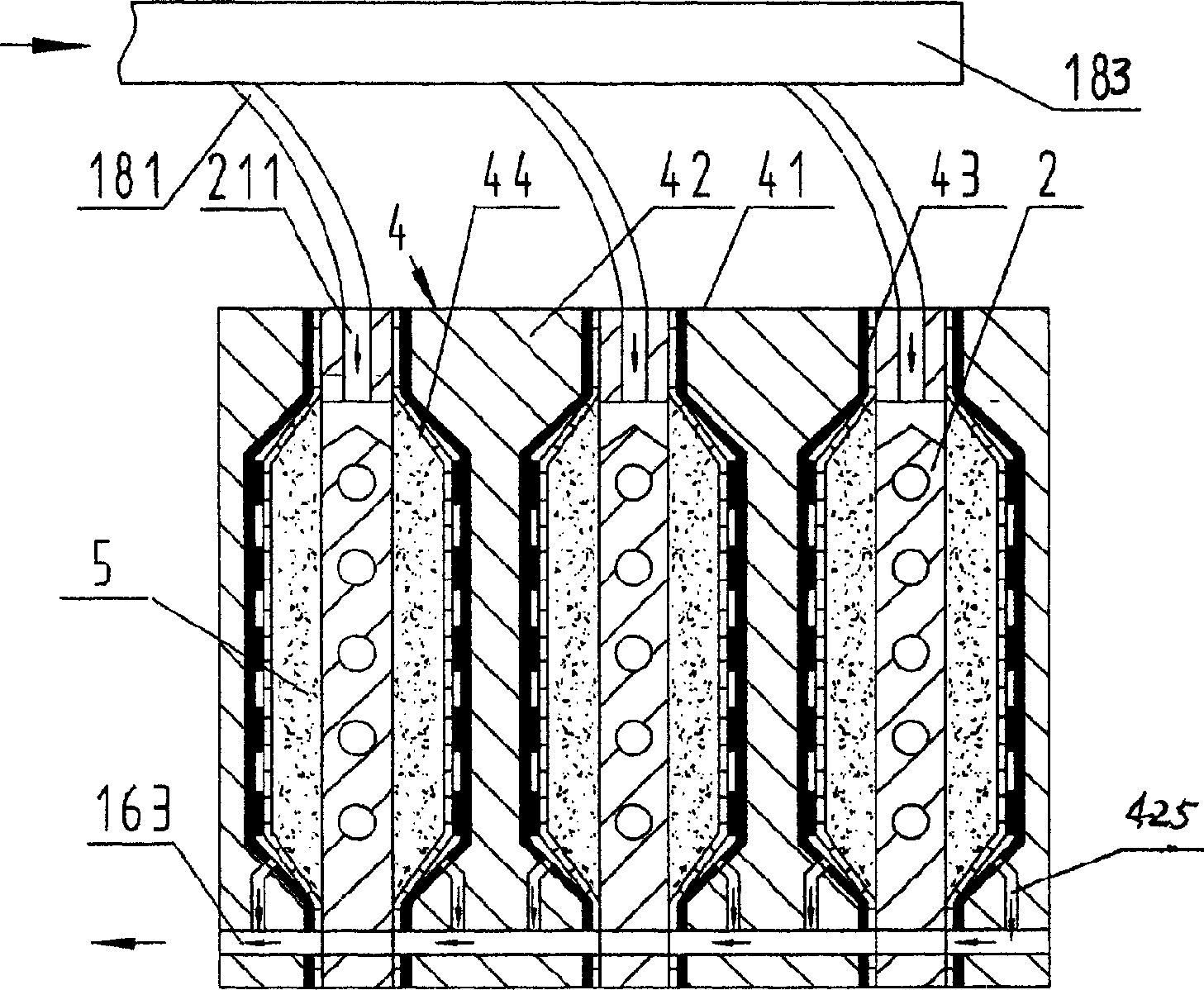

[0028] This embodiment is a process of carrying out the above-mentioned hot pressure filtration of a fine coal suspension. The six processes in the process are operated in sequence, and the vacuum degree of the filtrate drainage channel in the third process is controlled at 0.6MPa, control the extrusion pressure of the diaphragm to 0.6MPa, heat the drying plate to a temperature of 95-105°C, and keep it for 3-8 minutes, and it is ready. Adopting this embodiment can reliably reduce the moisture content of fine-grained flotation clean coal, flotation tailing coal and raw coal to 13-16% or lower, effectively solving the big problem of freezing in winter and the problem of ineffective railway water transportation , and thoroughly improve the storage and transportation characteristics of flotation tailings and primary coal slime products, making them value-added commodities from coal preparation by-products. In this way, it not only makes the cost of dehydration only 50% of that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com