Separator and phase-split conveying method for eliminating plug flow on serious segments by utilizing same

A separator and flow pipe technology, applied in the field of subsea separation and phase-separation transportation, can solve the problems of weakening severe slug flow, intermittent outflow of gas and liquid at the outlet, affecting wellhead pressure, etc., so as to eliminate serious slug flow, liquid level and pressure. Stabilizing and reducing the effect of inlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

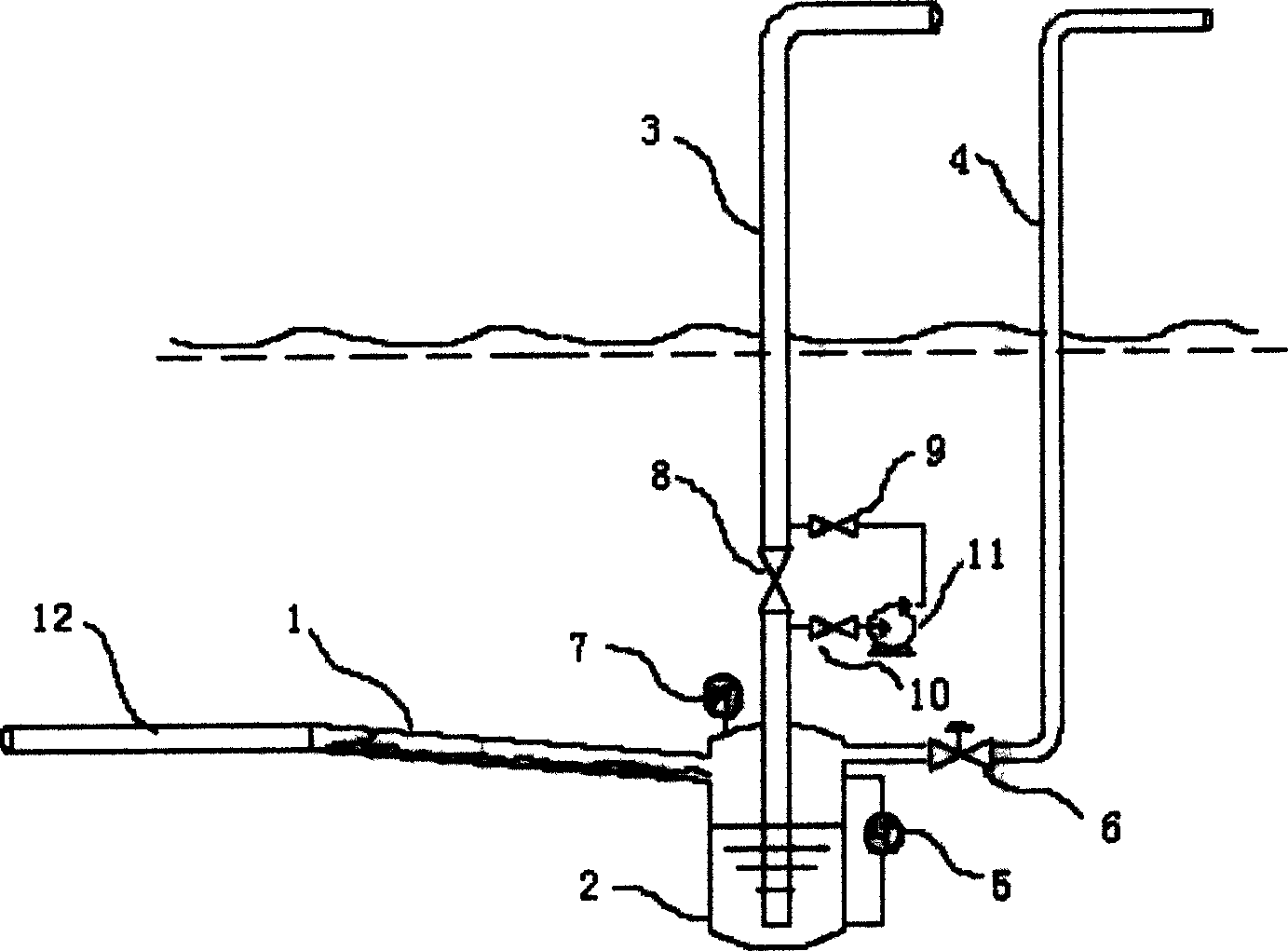

[0015] see figure 1 , the separator includes a shell 2, the shell 2 is connected with the flow pipe 1 and the gas riser 4, the liquid level sensor 5 and the pressure sensor 7 are arranged on the shell 2, the riser 3 is inserted into the shell 2 and extends to the shell At the bottom of the body 2, a valve 8 is installed on the part where the rising pipe 3 protrudes from the shell 2. The valve 8 forms a bypass with the liquid phase pump 11 through the valve 9 and the valve 10 at both ends of the rising pipe 3, and the gas rising pipe 4 is close to the shell. A control valve 6 is provided at the outlet of the body 2 .

[0016] The phase-separated conveying method to eliminate severe slug flow is to install a separator at the junction of the mixed transportation pipeline 12 and the rising pipe 3. The separator adopts tangential centrifugal separation, and its v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com