Cosmetic hair prepn.

A technology for hair cosmetics and compounds, applied in the directions of cosmetics, cosmetic preparations, hair care, etc., can solve the problems of not imparting softness or smoothness, disappearance of softness, and smoothness that will not last for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1~4

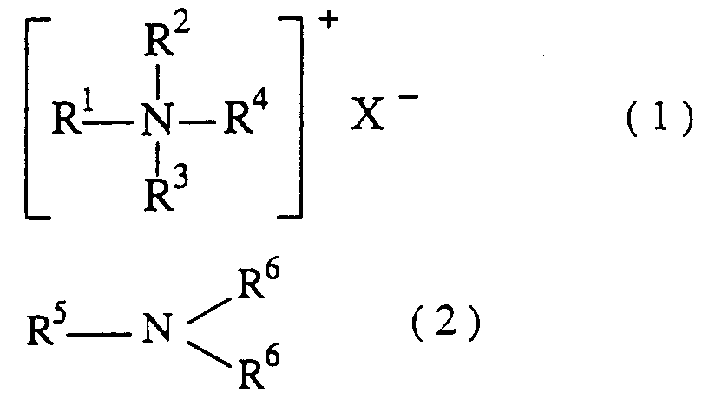

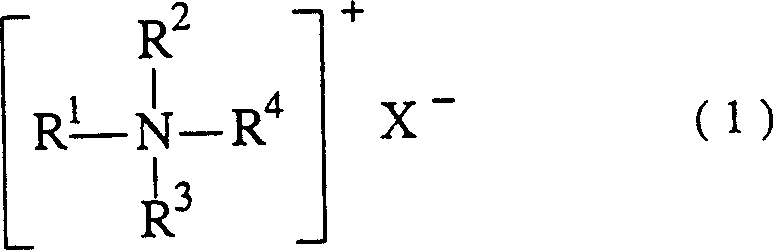

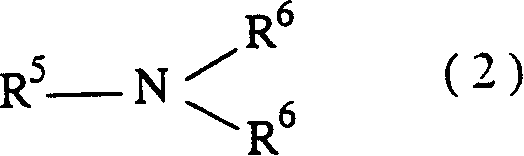

[0120] As the (A) component, copolymers 1 to 5 represented by the following general formula and FZ-3789 (amino-modified polysiloxane-polyoxyalkylene block copolymer manufactured by Japan Unicar Co., Ltd.) were used. Method The hair conditioner of the present invention having the composition shown in Table 1 and the hair conditioner as a comparison of the composition shown in Table 2 not using the component (A) were produced.

[0121] Copolymer 1:

[0122]

[0123] Copolymer 2:

[0124]

[0125] Copolymer 3:

[0126]

[0127] Copolymer 4:

[0128]

[0129] Copolymer 5:

[0130]

[0131] After washing with the following standard shampoo, the tester's hair was divided into two halves, and one half of the hair was coated with the hair conditioner of the present invention or as a comparison made above, and the other half was coated with the following standard hair conditioner. As for the silk agent, when rinsing, the stickiness, softness and smoothness in running...

Embodiment 2

[0162] A hair care shampoo having the following composition was manufactured in a usual manner.

[0163] Sodium polyoxyethylene lauryl ether sulfate solution 10.0%

[0164] (Average added moles of ethylene oxide = 2.5)

[0165] Stearyldimethylamine 0.1%

[0166] Cetyldimethylamine 0.1%

[0167]Cetyl Alcohol 0.5%

[0168] Amino-modified polysiloxane-polyoxyalkylene block copolymer 1.0%

[0169] (Made in Japan: FZ-3789)

[0170] Dimethicone 0.7%

[0171] (manufactured by TOSHIBA SILICONE: TSF451-10A)

[0172] Dimethicone 0.3%

[0173] (manufactured by TOSHIBA SILICONE: TSF451-50MA)

[0174] Lauryl Dimethylamine Oxide 1.0%

[0175] Betaine Lauryl Carboxymethyl Hydroxyethylimidazolium Salt 1.0%

[0176] Cationized Cellulose 0.5%

[0177] Propylene Glycol 0.5%

[0178] Ethylene Glycol Distearate 2.0%

[0179] 50% citric acid aqueous solution appropriate amount

[0180] Fragrance, Methylparaben Appropriate amount

[0181] Purified water balance

[0182] pH 3.5

[01...

Embodiment 3

[0185] A hair combing agent having the following composition was produced according to a usual method.

[0186] Behenyltrimethylammonium Chloride 8.0%

[0187] Behenyl Alcohol 7.0%

[0188] Amino-modified polysiloxane-polyoxyalkylene block copolymer 5.0%

[0189] (Made in Japan: FZ-3789)

[0190] Dimethicone 0.7%

[0191] (manufactured by TOSHIBA SILICONE: TSF451-10A)

[0192] Dimethicone 0.3%

[0193] (manufactured by TOSHIBA SILICONE: TSF451-50MA)

[0194] Polyoxyethylene sorbitan monostearate 0.5%

[0195] (Average added moles of ethylene oxide = 20)

[0196] Behenic Acid 1.0%

[0197] Dipropylene glycol 6.0%

[0198] Glycerin 10.0%

[0199] 50% citric acid aqueous solution appropriate amount

[0200] Fragrance, Methylparaben Appropriate amount

[0201] Purified water balance

[0202] pH 4.8

[0203] This hair grooming agent has a strong soft feeling when applied, and shows a soft and smooth feeling without any sticky feeling when rinsed off. And when you use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com