Sheet conveying apparatus, sheet treating apparatus and image forming apparatus

A technology for conveying devices and sheets, applied in the fields of image forming devices and sheet processing devices, which can solve the problems of high cost and large-scale devices, and achieve the effect of low cost and small power supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0030] (first embodiment)

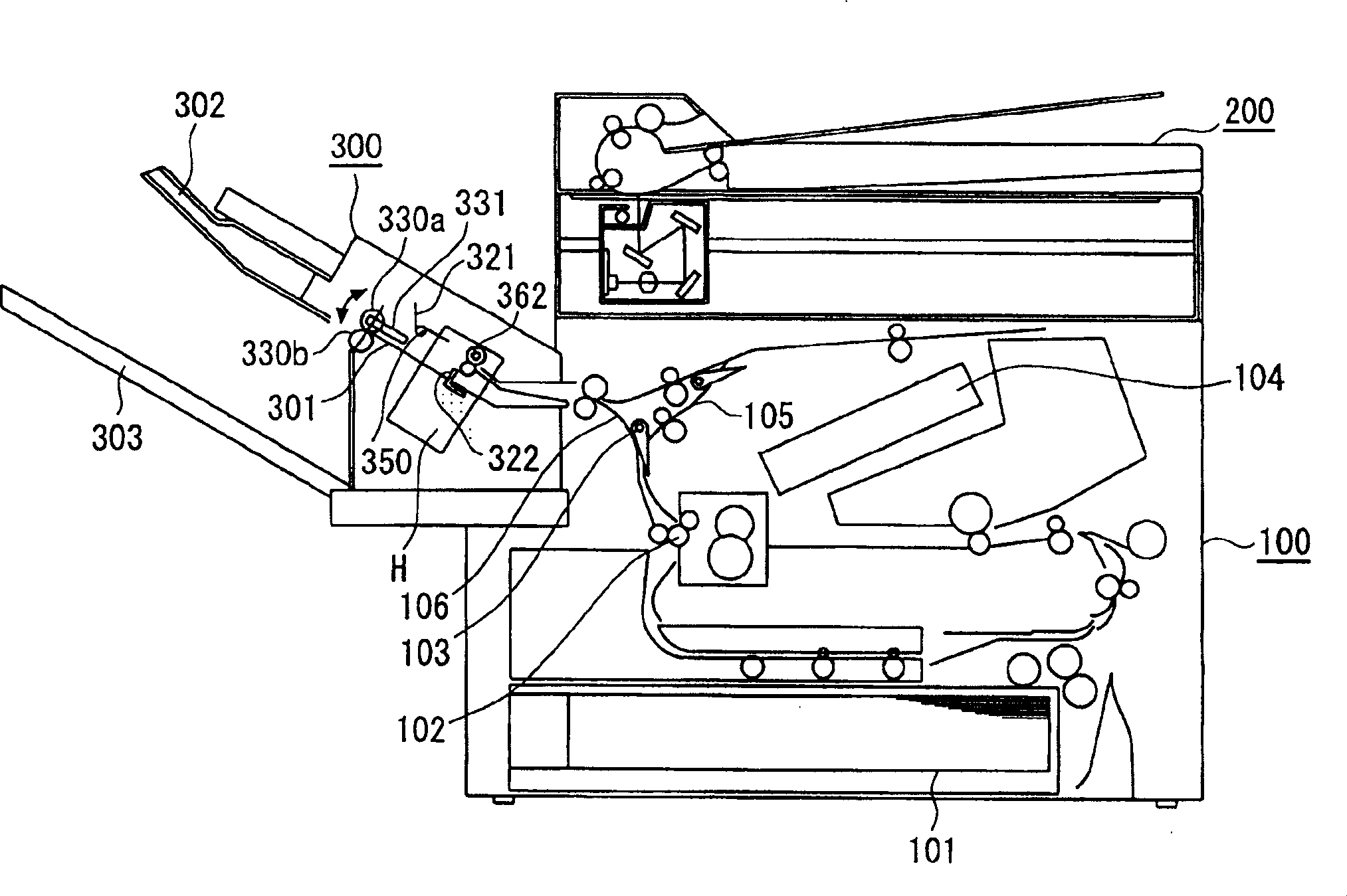

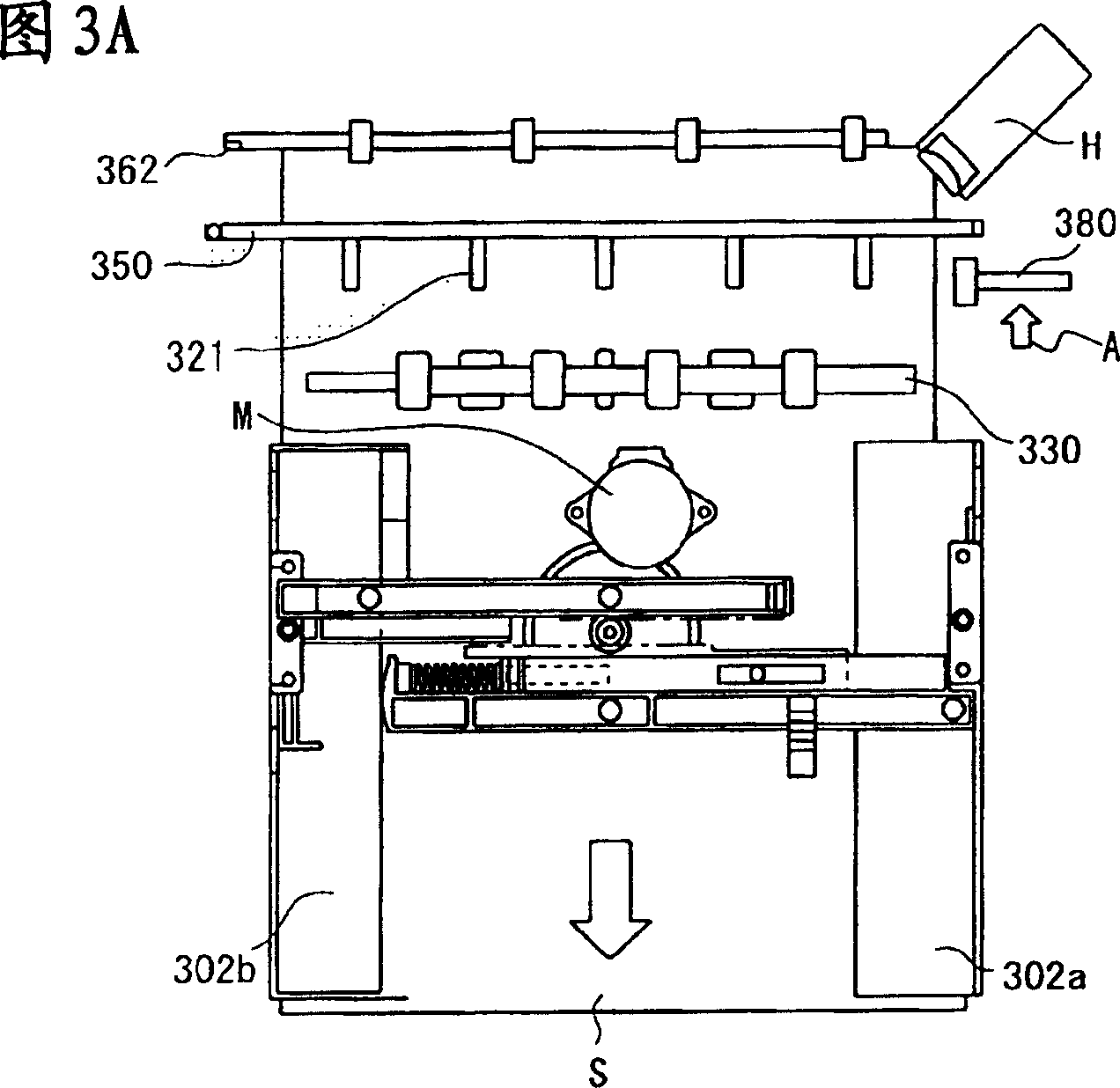

[0031] figure 1 It is a cross-sectional view of an image forming processing system composed of an image forming apparatus including a sheet processing apparatus and an image reading apparatus of the present invention.

[0032] exist figure 1 In the figure, reference numeral 100 is a printer having an image reading unit 200 , and two discharge paths are set after image formation is performed on paper supplied from a paper feed cassette 101 . First, the paper is conveyed in a U-turn to the upper part of the writing scanner 104 by the fixing discharge roller 102 and the roller pair 103, the A conveyance path 105 for reverse conveyance, and the B conveyance path 106 for direct conveyance.

[0033] In addition, after the sheet processing apparatus 300 loads the sheets discharged from the printer main body 100 on the first stacker 301, the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com