Cutting tool head for a metal working tool

一种工具头、机床的技术,应用在工具头领域,能够解决多空间、占用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

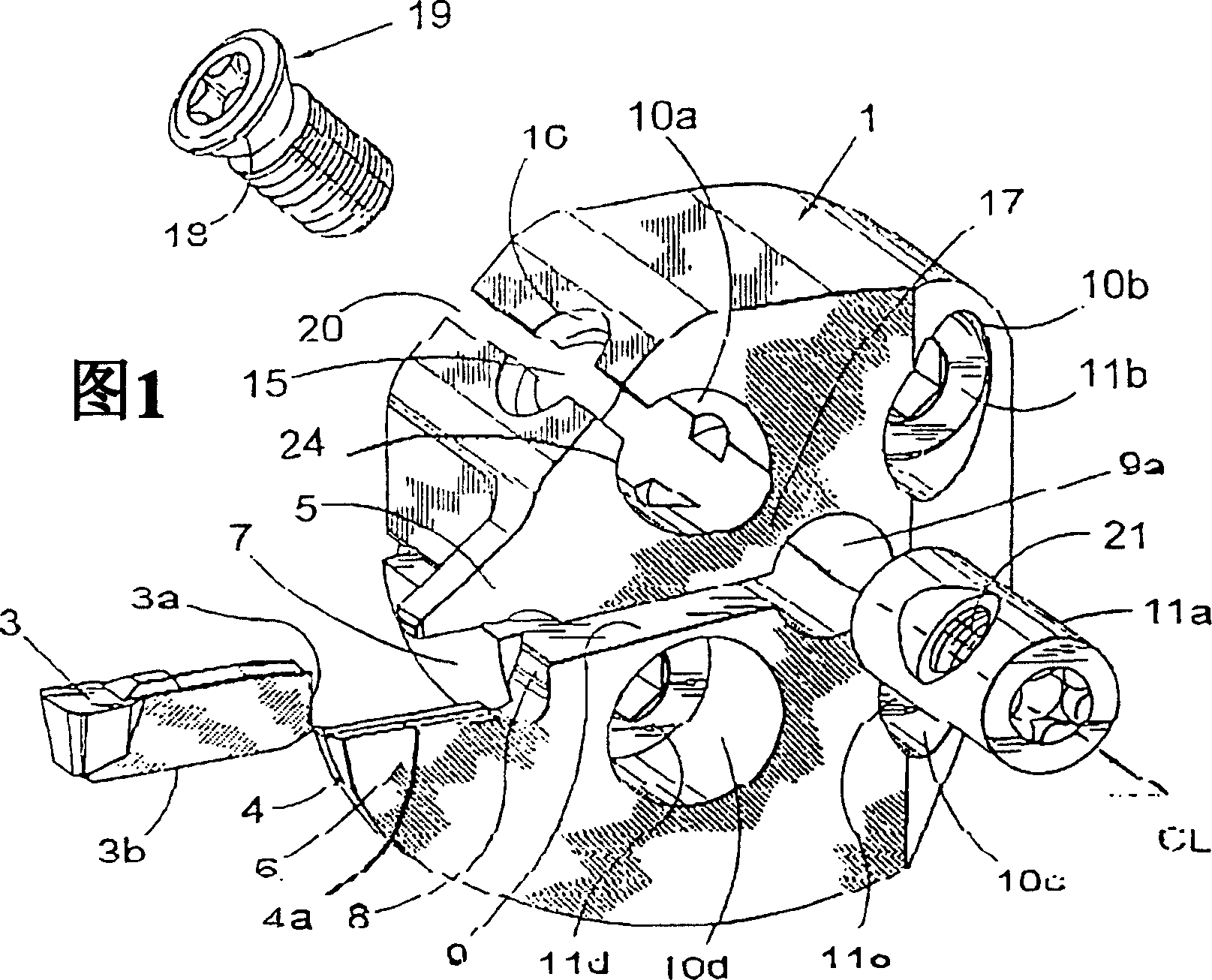

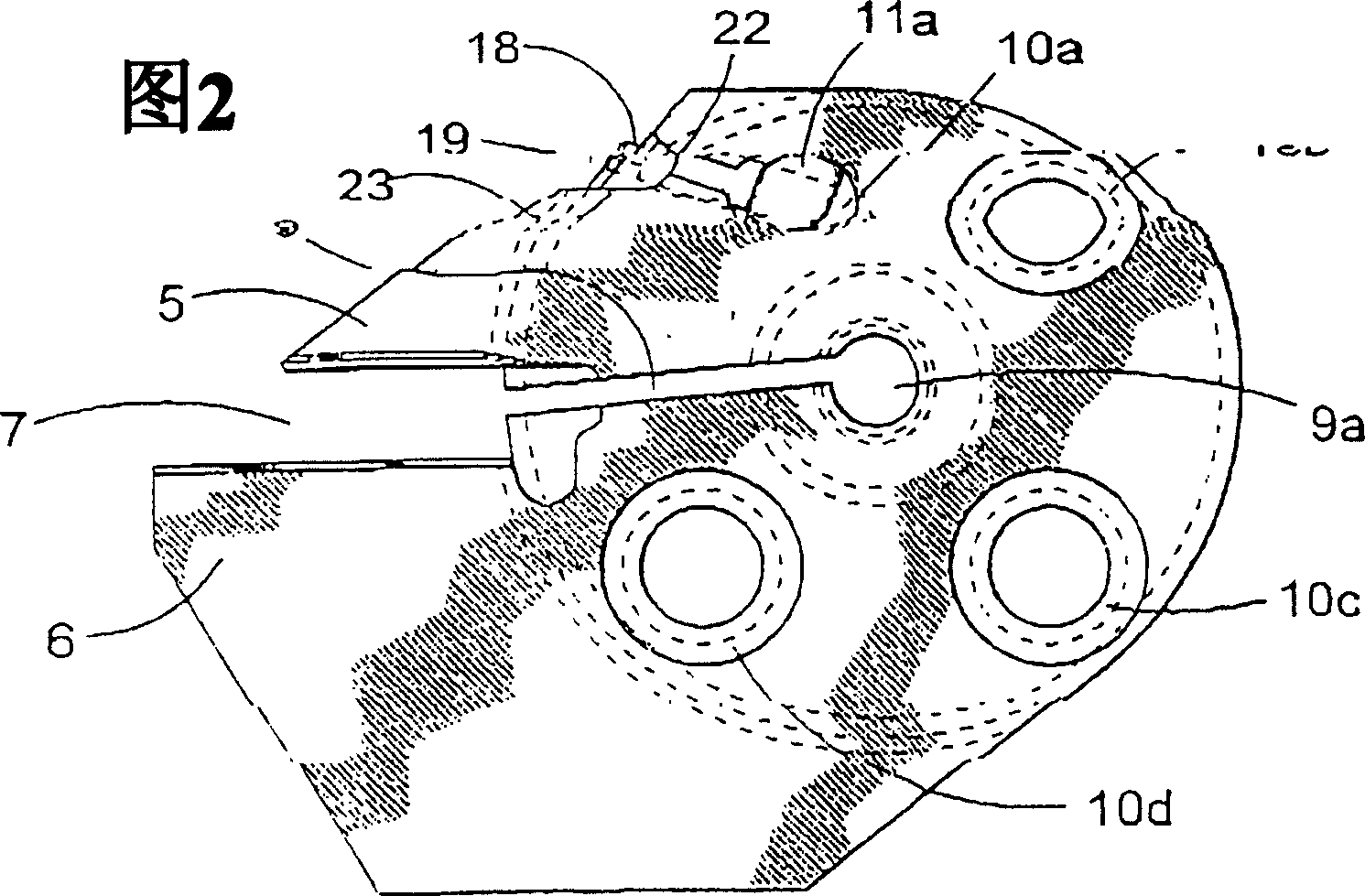

[0011] Fig. 1 shows a tool head for a metal removal machine tool according to a preferred embodiment of the present invention. The tool head includes a main holder 1 having a central hole 9a for engagement with a machine tool. The main clamp 1 has a blade clamp 4 connected thereto, which is formed in the shape of a forward transverse boss. Preferably, the master clamp is adapted to be connected to a machine tool, such as a multifunction lathe, by an engaging member suitable for the purpose. The front part of the insert holder 4, i.e. the front part of said forward transverse projection, is constituted by a blade-shaped part in which an insert pocket 7 in the form of a fixed pocket is provided to accommodate a cutting insert 3 for chip removal machining. . A blade pocket 7 is formed between a lower support portion 6 for supporting the blade 3 and an upper fixing portion 5 integrally formed with the lower support portion 6 , wherein the upper fixing portion 5 has a width small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com