Process for extracting material from mineral waste material by high-intensity magnetic field gradient

A magnetic field gradient and mineral waste technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems affecting the refining process, insufficient extraction strength, and poor quality of extracts, achieving good economic benefits and strong throughput capacity , the effect of fast extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the extraction of titanium concentrate from iron ore waste as an example:

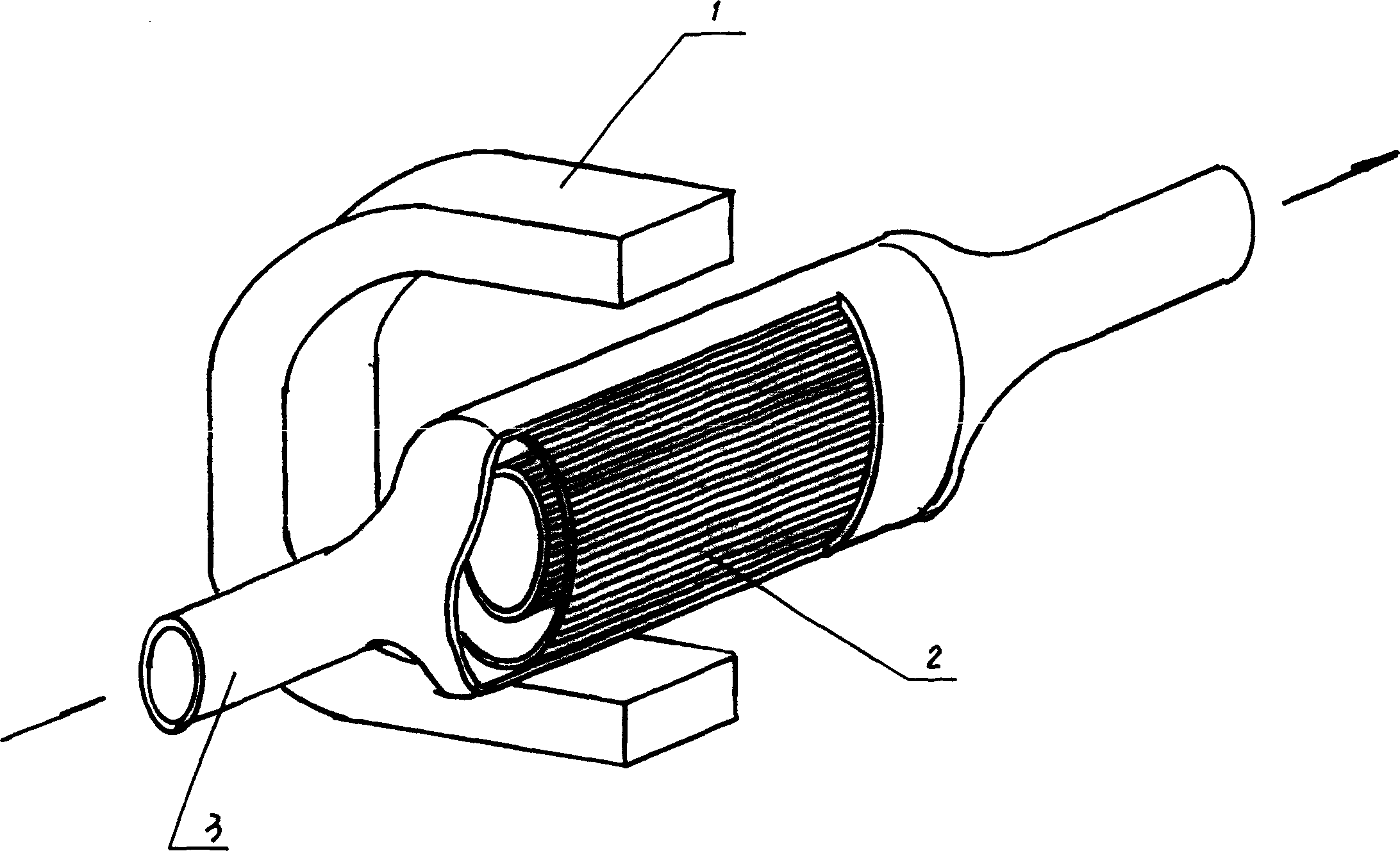

[0023] First set up a strong magnetic field area, which generates 4×10 6 The magnetic field strength of A / m (together with 5 Tesla), and the secondary magnetic pole device is set in the area. The device is made of strong magnetic stainless steel and takes the form of an array of metal wires. The metal wires are made of wire mesh or metal wool. The diameter of the wire is selected according to the particle size of the ilmenite component in the mineral waste, and the optimal stacking factor of the secondary magnetic pole array is below 15%. The device with this structure can generate a magnetic field gradient on the order of 100,000 Tesla / m.

[0024] This type of iron ore waste usually contains titanium concentrate and various silicate substances containing magnetite. Titanium concentrate is a kind of permanent magnetic substance. In some cases, it is weakly and strongly magnetic because the...

Embodiment 2

[0028] Taking the extraction of impurities from the titanium concentrate extracted from embodiment 1 is an example:

[0029] Set a strong magnetic field area, which produces 1.2×10 6 The magnetic field strength of A / m (1.5 Tesla), and the secondary magnetic pole device is set in the area. The device is made of strong magnetic stainless steel and takes the form of an array of metal wires. The metal wires are made of wire mesh or metal wool. The diameter of the wire is selected according to the particle size of impurities in the titanium concentrate, and the optimal stacking factor of the secondary magnetic pole array is below 15%. The device with this structure can generate a magnetic field gradient of the order of 100,000 Tesla / m.

[0030] The extracted titanium concentrate is mixed in water, and the material is sent to and passed through the secondary magnetic pole device by the conveying pipeline. When the material passes through the secondary magnetic pole device, the impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com