Integrated device of semiconductor laser and wedge shaped waveguide modular speckle converter

A technology of speckle converter and wedge waveguide, which is applied in the field of optoelectronic integrated devices, can solve the problems of complex structure of speckle converter, difficult coupling, low yield of integrated devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

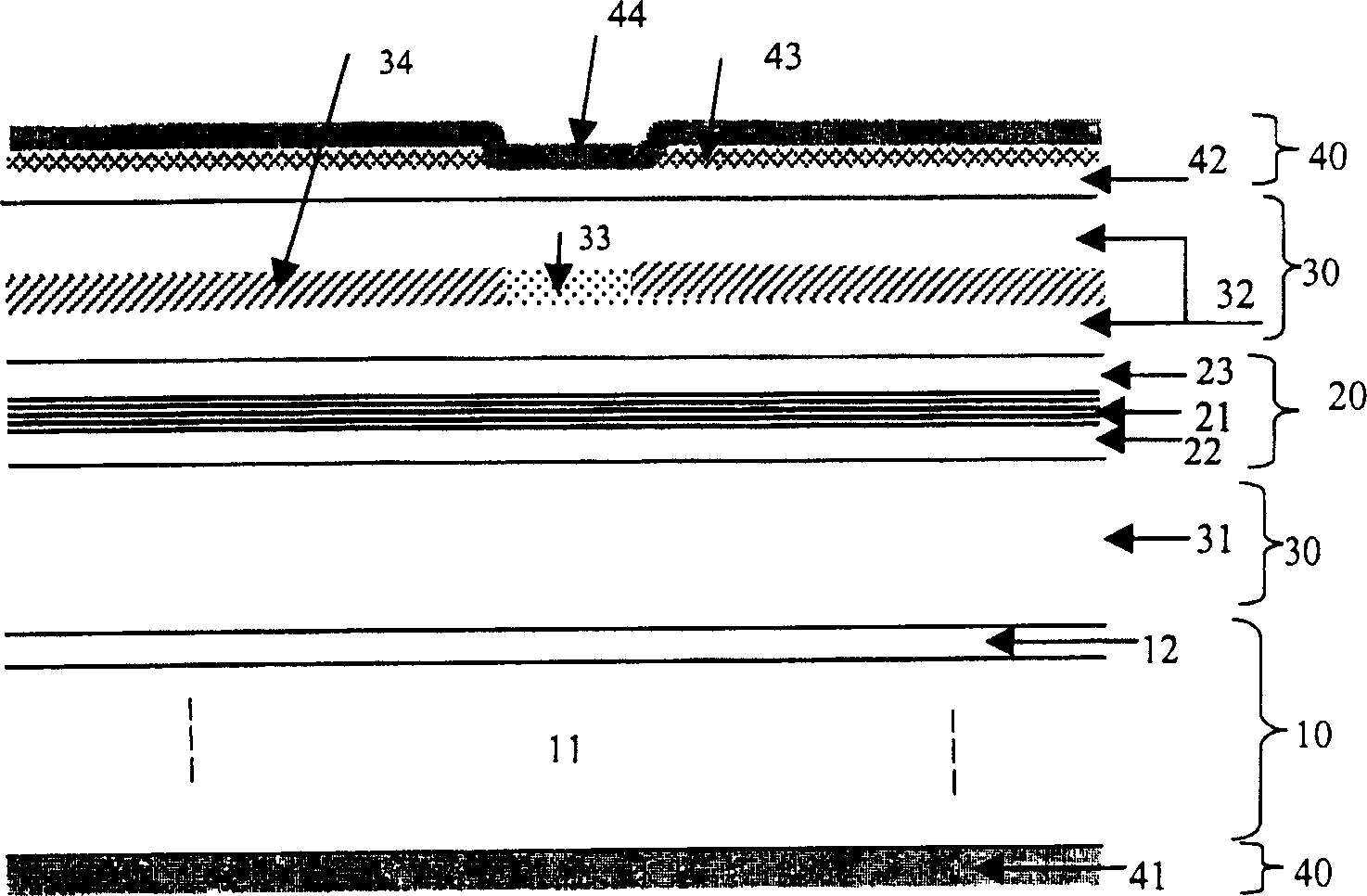

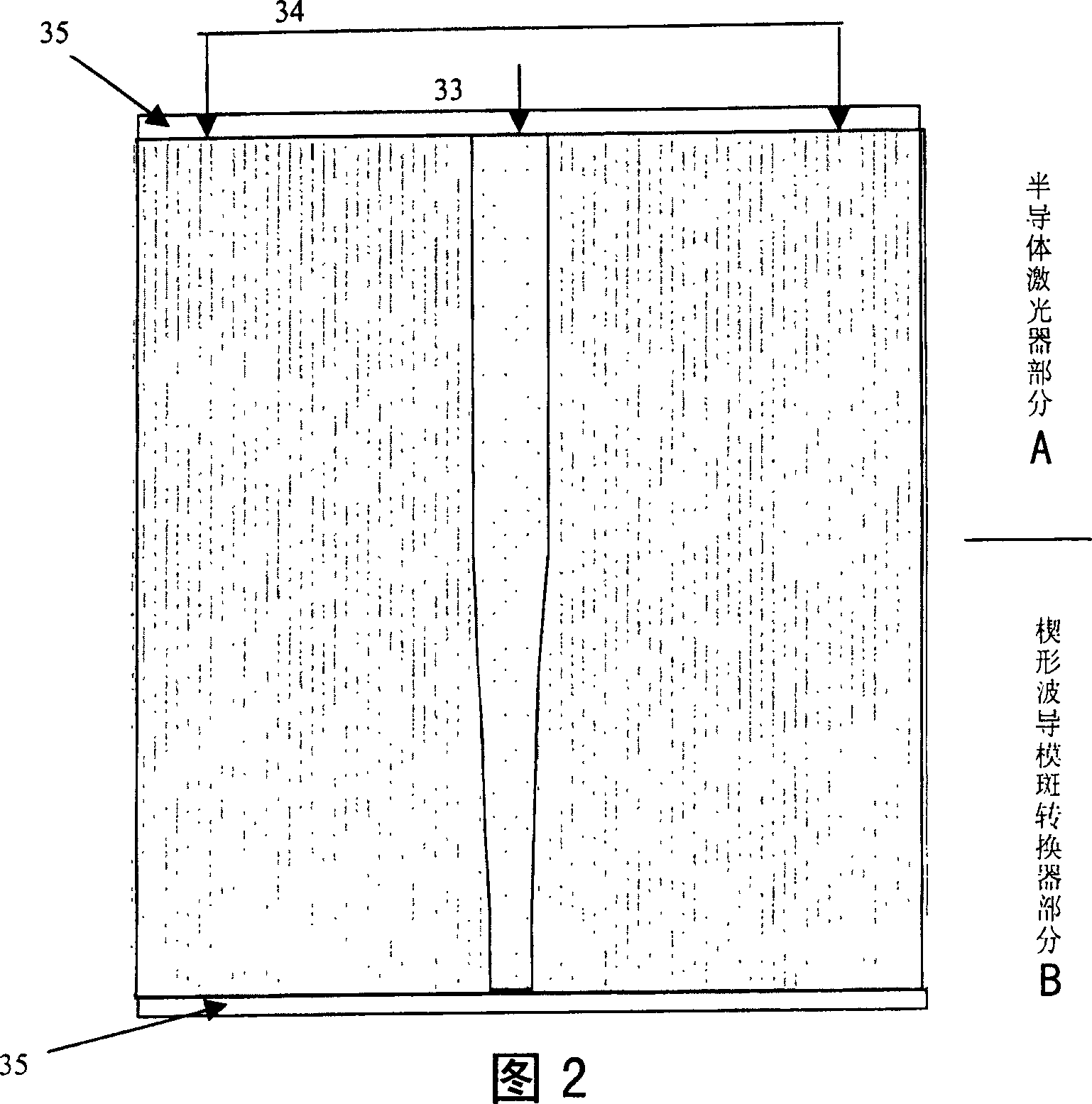

[0021] Combine below figure 1 and Fig. 2 illustrate the basic structure of the device of the embodiment of the present invention.

[0022] The basic structure of the device in this embodiment includes four regions: a substrate region 10 ; a light guiding region 20 ; a confinement region 30 ; and an electrode region 40 . The following is the specific structure of the device of this embodiment:

[0023] The substrate area 10; the substrate area 10 specifically includes:

[0024] n-type heavily doped indium phosphide substrate 11;

[0025] n-type doped indium phosphide buffer layer 12,

[0026] The light guide area 20, the light guide area 20 specifically includes:

[0027] The active layer 21 is not doped,

[0028] Undoped InGaAsP lower waveguide layer 22;

[0029] Undoped InGaAsP upper waveguide layer 23;

[0030] Restricted area 30, specifically restricted area 30 includes:

[0031] n-type doped indium phosphide lower confinement layer 31;

[0032] p-type doped indium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com