Wafer radiating element

A technology for heat-dissipating components and wafers, which is applied to electrical components, electrical solid-state devices, semiconductor devices, etc., and can solve problems such as affecting the filling process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

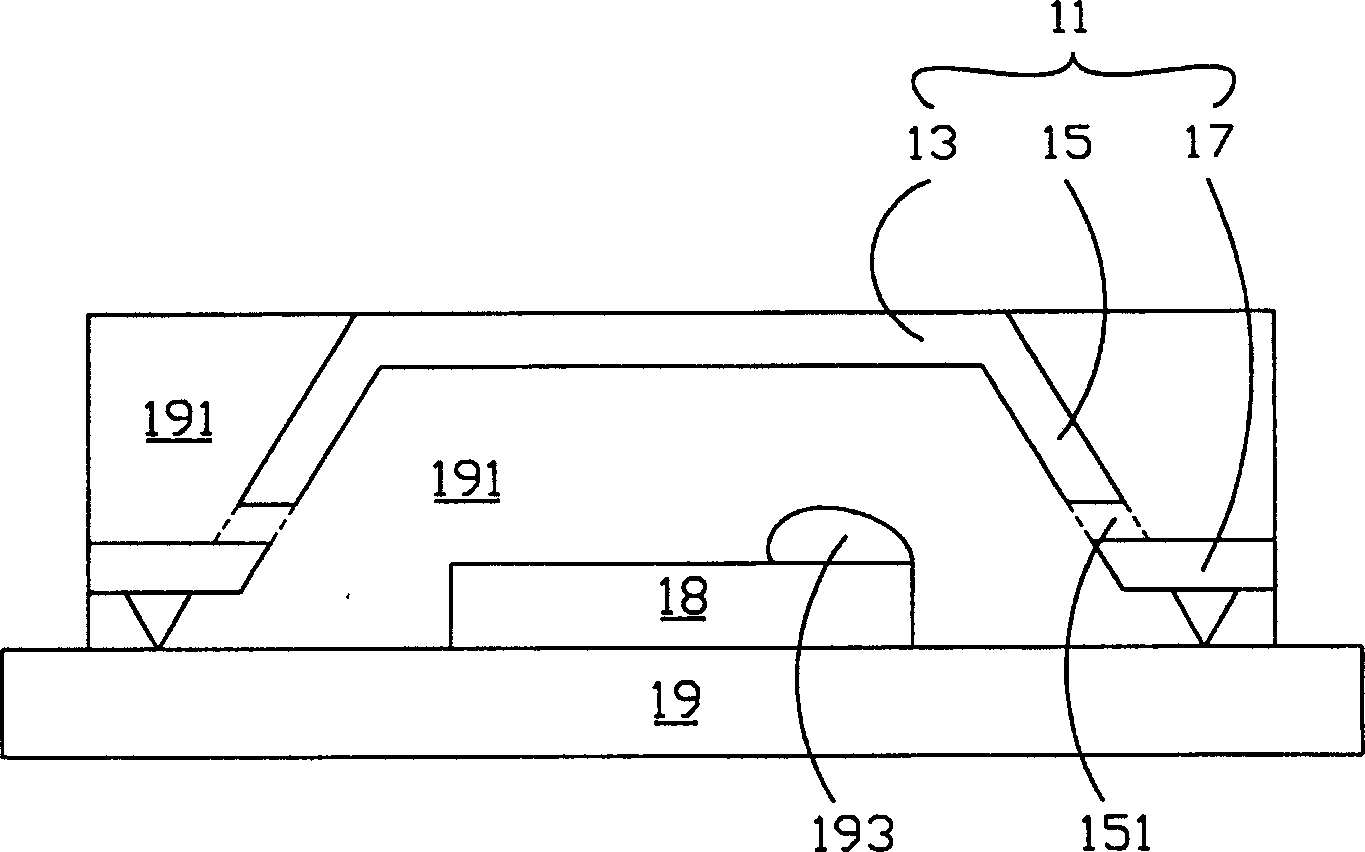

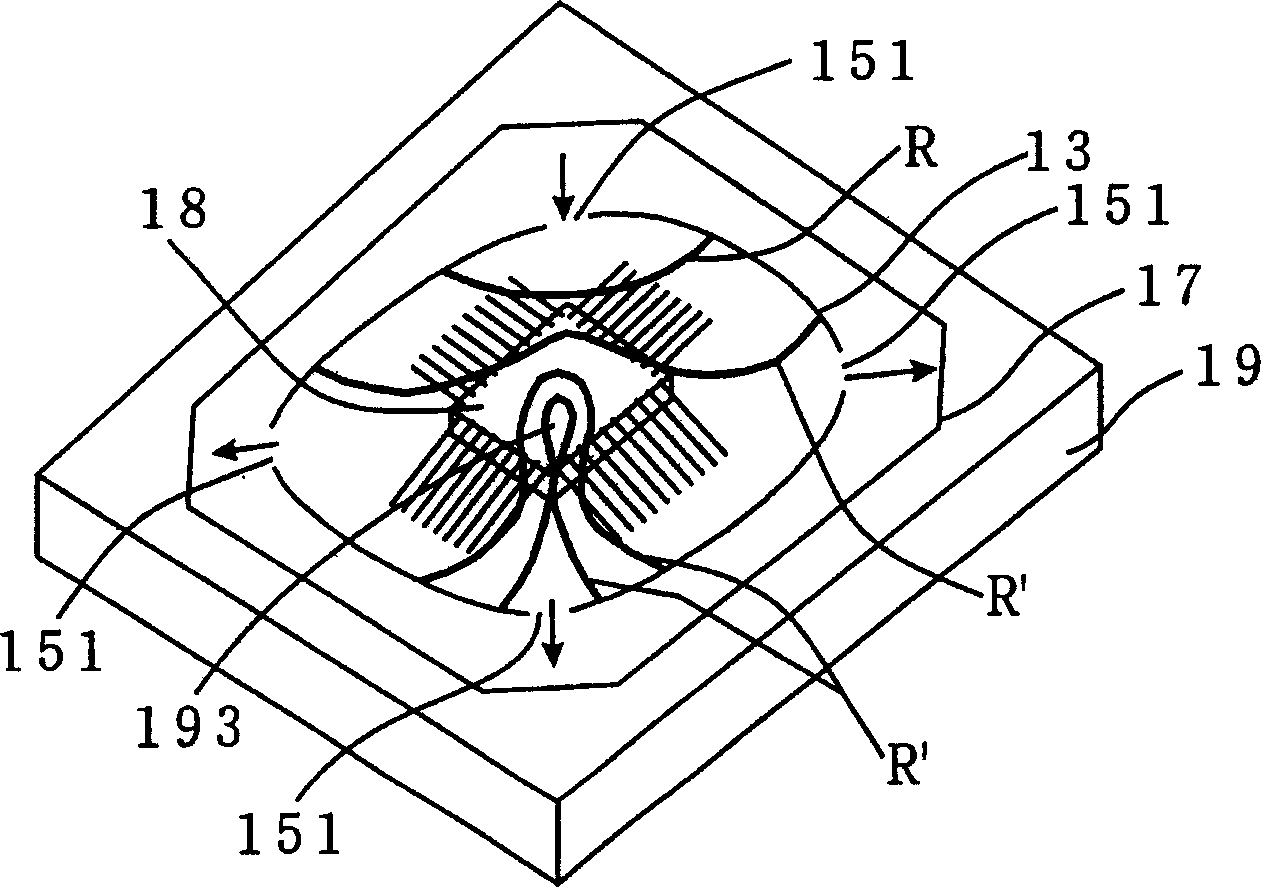

[0024] The present invention is mainly a chip cooling element, which will be described in detail below. The embodiment of the present invention is mainly to solve the problems described in the prior art, but the patent scope of the present invention is not limited to the following figures and descriptions of the embodiments, but should be based on the scope and spirit of the applied patent allow.

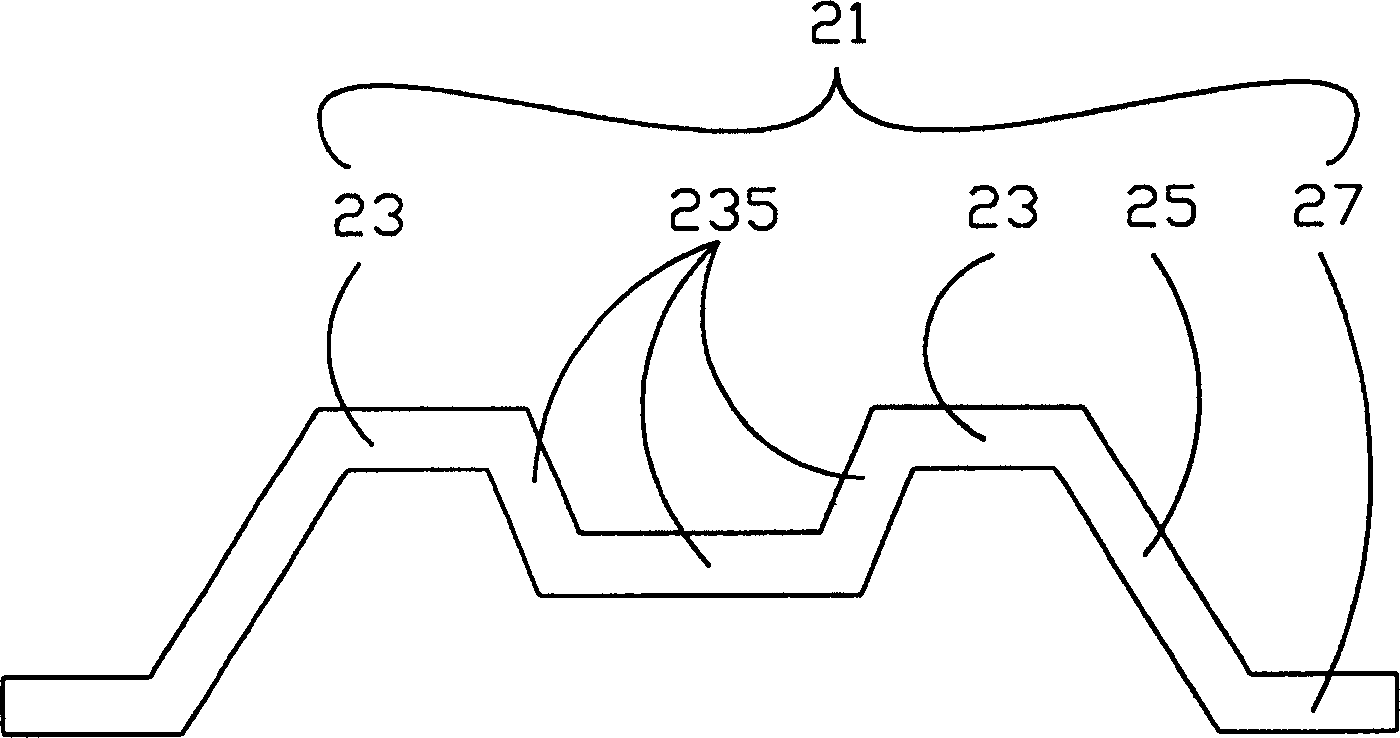

[0025] The first embodiment of the wafer cooling element 21 of the present invention is as figure 2 As shown, there is a top plate 23, side walls 25 and bottom plate 27. The top plate 23 is bent and extended to connect to the side wall 25 , and the side wall 25 is bent and extended to connect to the bottom plate 27 . The top plate 23 has a recessed plate portion 235 .

[0026] Such as image 3 As shown, the chip cooling element 21 is applied on a chip 33 , contacts and is fixed on part of the chip 33 through the concave plate portion 235 , and the bottom plate 27 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com