Configuration method of combined factory building for producing anode carbon brick for electrolysis of aluminum

A technology of anode carbon block and configuration method, which is applied in the field of configuration of a combined workshop for the production of anode carbon blocks for electrolytic aluminum, can solve the problems of inability to continuously transport materials, increase the paved area of roads and pipelines, and increase investment in infrastructure, etc. The effect of reducing road paving area and pipeline laying length, reducing capital construction investment and production and operation costs, reducing loading and unloading links and material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

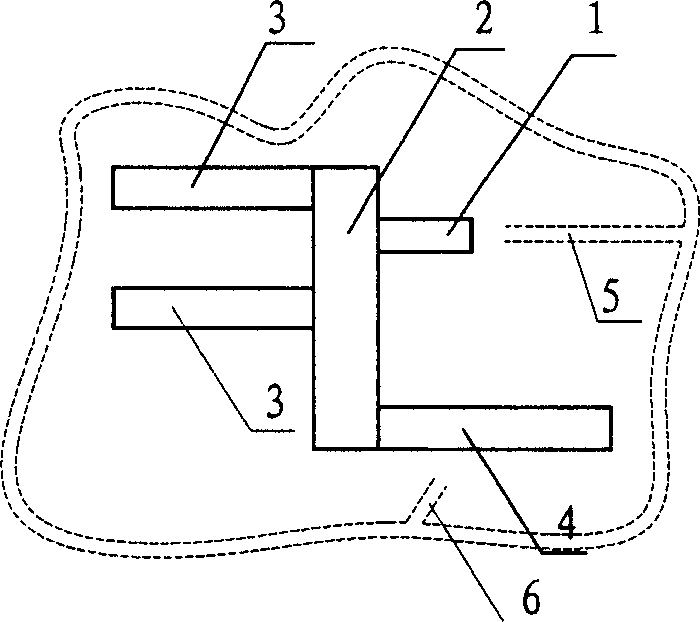

[0008] Embodiment 1 of the present invention: as figure 1 As shown, the carbon block transfer section (2) is placed in the center, and the two parallel roasting sections (3) are placed on one side of the carbon block transfer section (2) and adjacent to the carbon block transfer section (2) And vertically, place the raw anode manufacturing and cooling section (1) on the other side of the carbon block transfer section (2), perpendicular to it, adjacent to and close to the raw material inlet (5), and place the anode assembly section (4) on the raw anode The position on the same side of the manufacturing and cooling section (1), and perpendicular to the carbon block transfer section (2), is adjacent to and close to the finished product outlet (6), and the material transportation between the sections adopts chain or plate conveyors.

Embodiment 2

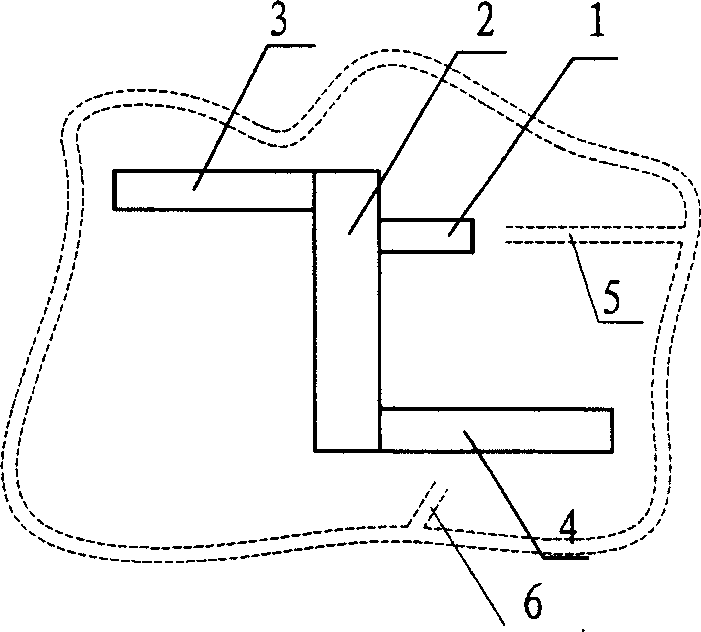

[0009] Embodiment 2: as figure 2 As shown, when the roasting section (3) is arranged as a factory building, the carbon block transfer section (2) is placed in the center, and the roasting section (3) is placed on one side of the carbon block transfer section (2) and the carbon block The transfer section (2) is adjacent and vertical, and the layout of other sections is the same as that in Embodiment 1, and chain or plate conveyors are also used for material transportation between sections. When building a factory in a mountainous area for layout, the raw anode manufacturing and cooling section (1), the carbon block transfer section (2), the roasting section (3), and the anode assembly section (4) can be arranged on tables of different elevations. Generally 2 ~ 4m. The relative position of each section can be adjusted according to specific conditions such as the topographical conditions of the factory and the direction of external material transportation in practical applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com