Process for treating orientation texture of thermoelectric ceramic material

A technology of ceramic materials and thermoelectric materials, which is applied in the field of orientation texture treatment of thermoelectric ceramic materials, can solve the problems of complex process, limited application, long process time, etc., and achieve the effect of obvious effect and improved thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

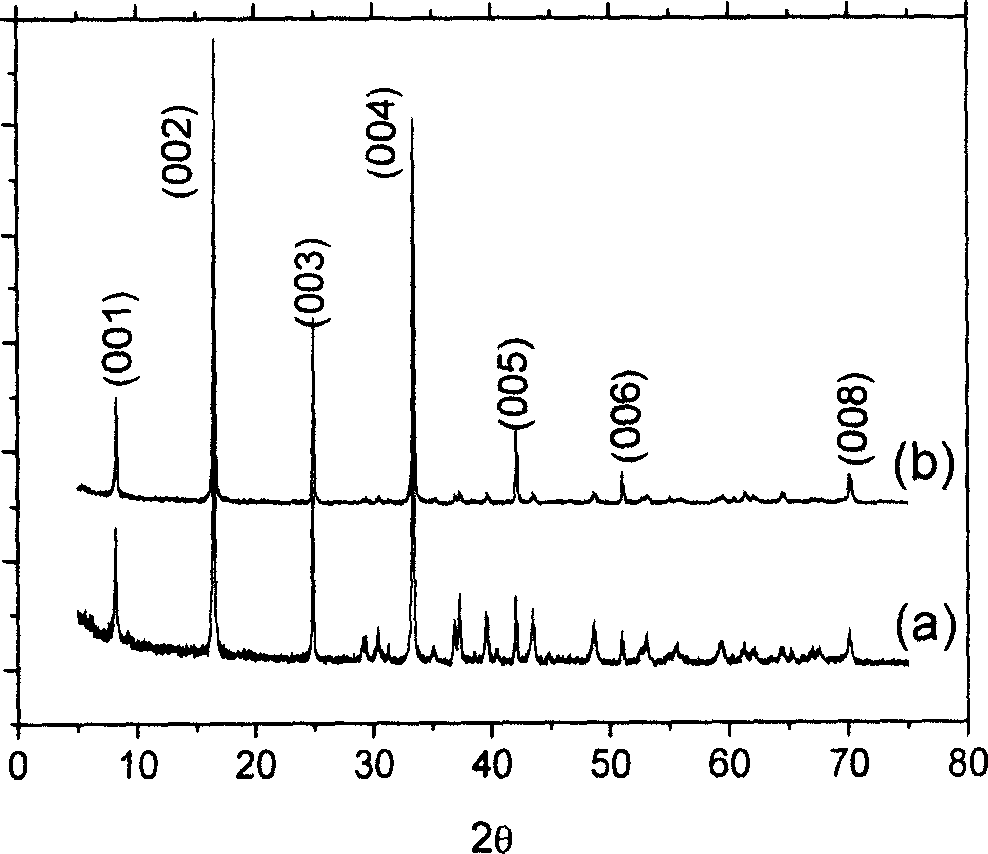

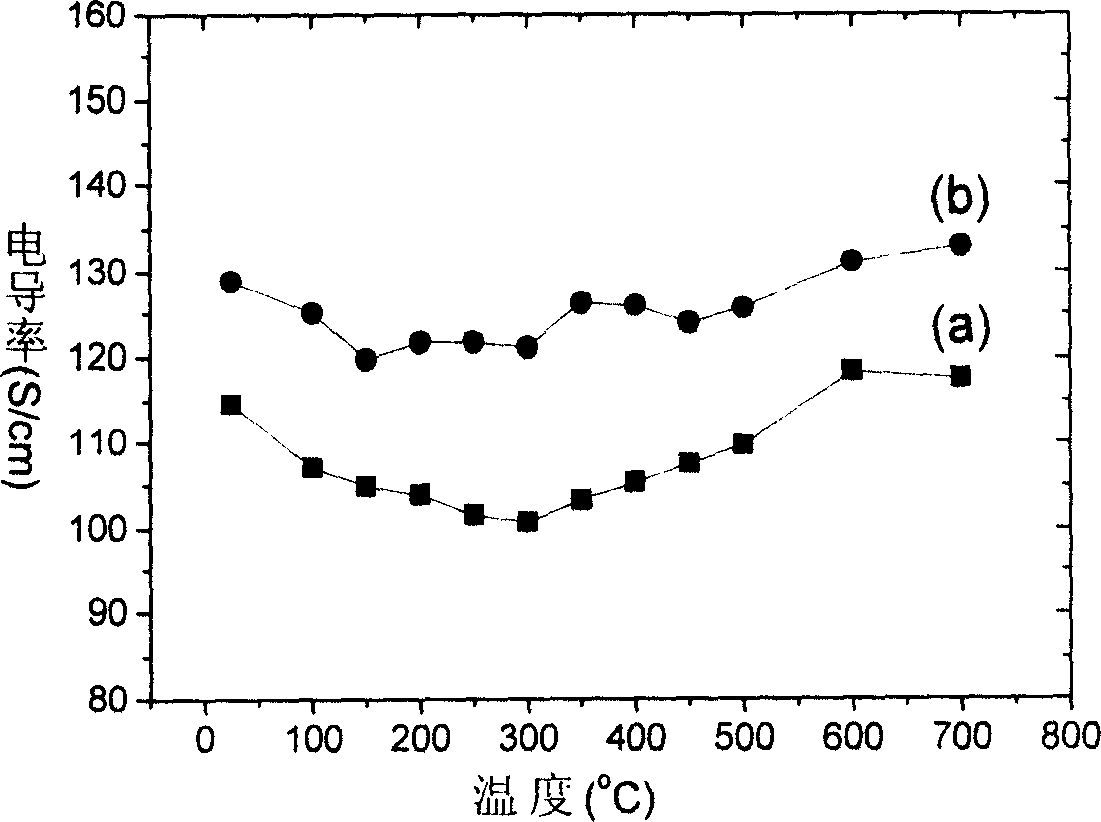

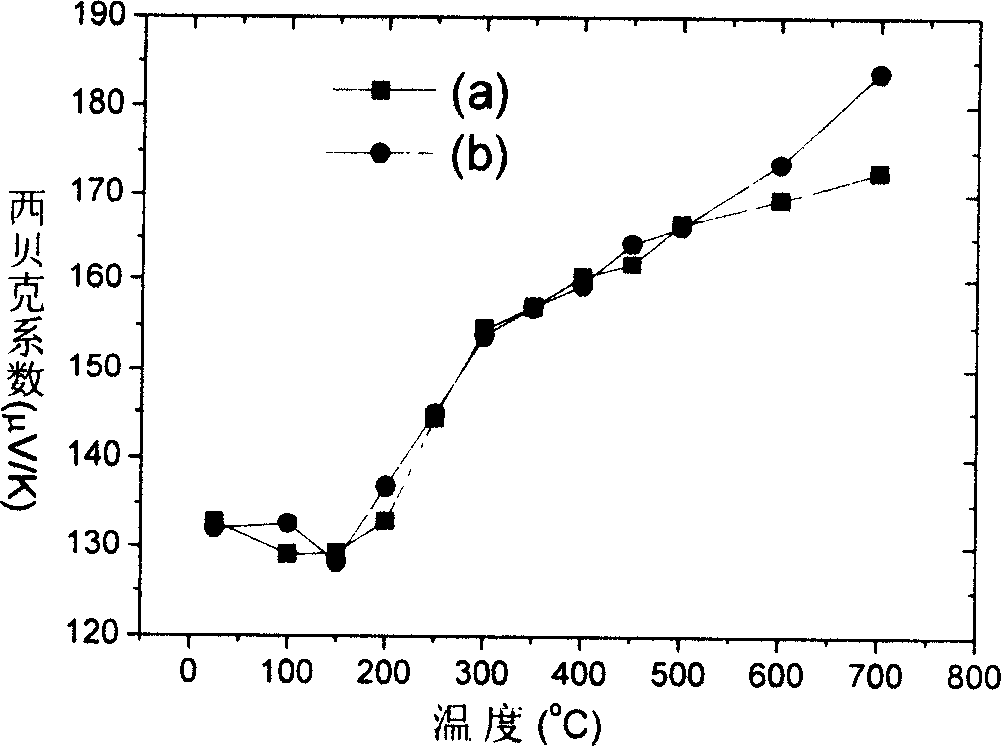

[0018]Weigh a certain amount of Ca(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O and citric acid, Ca-Co-O-based ceramic precursor powder was synthesized by sol-gel method. The XRD spectrum shows that the precursor powder has no other impurity phases. Pour a certain amount of precursor powder into a graphite mold, place the mold in an SPS furnace, apply a constant pressure of 50MPa, and sinter at 750°C for 5 minutes to obtain a density of 98.1%. Ca-Co-O-based thermoelectric materials. figure 1 The XRD analysis shown shows that the phase is a single Ca 3 co 4 o 9 The sintering performance is good, and the Logtering orientation factor calculated according to the XRD spectrum is only 0.31, indicating that SPS sintering does not lead to obvious orientation texture, and the role of SPS is mainly to obtain a high-density ceramic green body. The thermoelectric performance test shows that the conductivity of the sample is 117.74S / cm at 700°C, the Seeback coefficient is 172.63μV / K, and the pow...

Embodiment 2

[0020] After the SPS sintered ceramic body in Example 1 was calcined to remove carbon, it was placed in a hot forging furnace at 900°C, and a certain pressure load of 40 MPa was applied to cause lateral deformation, thereby obtaining a highly oriented thermoelectric ceramic with good performance. XRD analysis of the Ca-Co-O-based hot-forged samples showed that ( figure 1 As shown), the (001) peak intensity of the hot-forged sample is significantly enhanced, and the Logtering orientation factor is 0.82, indicating that the hot-forged sample has a high degree of orientation arrangement structure. At 700°C, the conductivity of the sample is 133.10S / cm, the Seeback coefficient is 183.81μV / K, and the power factor is 4.50×10 -4 w -1 K -2 . Its corresponding data such as figure 1 , figure 2 , image 3 , Figure 4 (b) shown.

Embodiment 3

[0022] Weigh a certain amount of Ca(NO 3 ) 2 , La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and citric acid, La-Ca-Co-O-based ceramic precursor powder was synthesized by sol-gel method. The XRD spectrum shows that the precursor powder has no other impurity phases. Pour a certain amount of precursor powder into a graphite mold, place the mold in an SPS furnace, apply a constant pressure, and sinter at 750°C for 5 minutes to obtain a density of 98.4%. La-Ca-Co-O-based thermoelectric materials. XRD shows that the phase is single (Ca 0.9 La 0.1 ) 3 co 4 o 9 Solid solution phase, good sintering performance, according to XRD spectrum ( Figure 5 Shown) the calculated Logtering orientation factor is only 0.40, SEM ( Figure 6 ) also shows that there is no obvious orientation arrangement of the grains, indicating that SPS sintering alone cannot introduce a highly oriented texture, but compared with Ca-Co-O-based thermoelectric materials, the incorporation of La is more condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com