Manganese zinc ferrite soft magnet and its manufacturing method

A manganese-zinc ferrite and soft magnetic technology, which is applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of unconsidered, power consumption deterioration, etc., and achieve the goal of reducing power consumption and easy adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

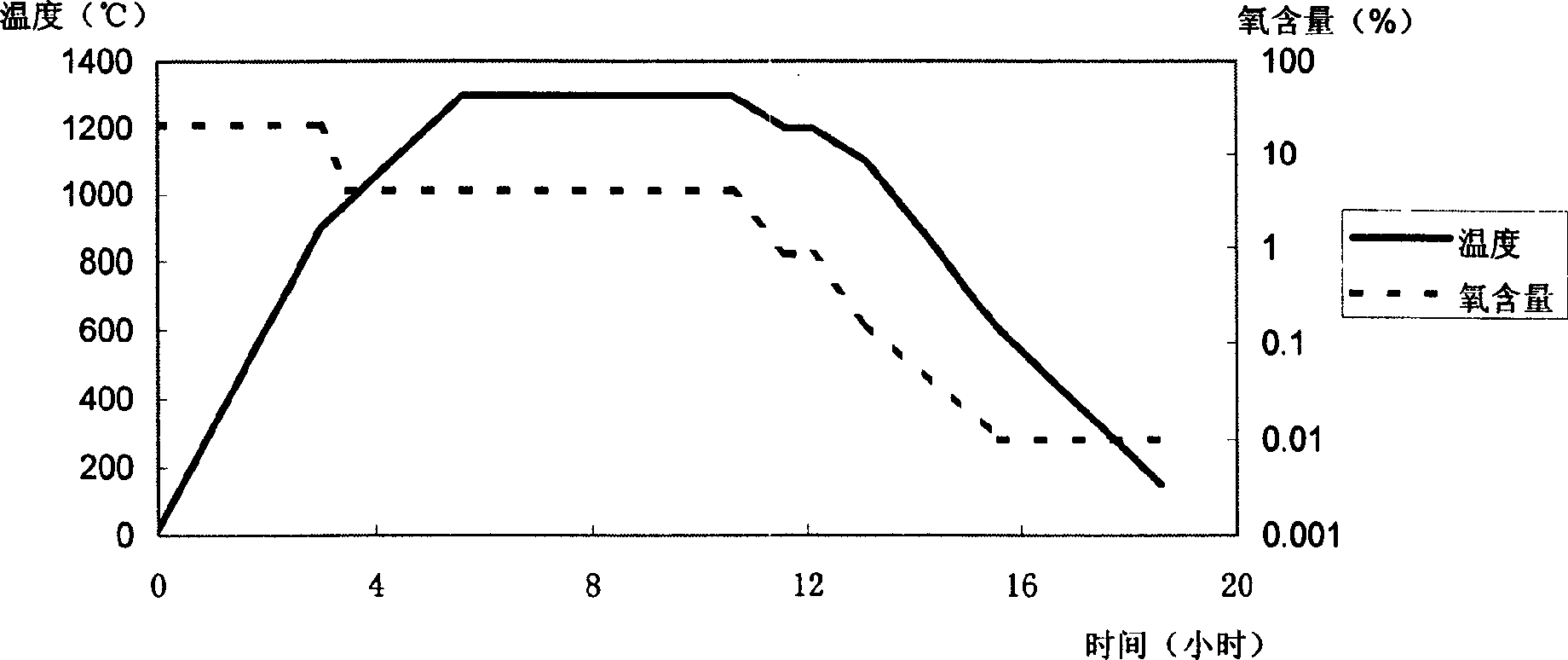

[0028] Embodiment 1, sintering according to the following steps shown in Fig. 2 curve:

[0029] ① Heating rate up to 900°C: 300°C / hour;

[0030] ② Heating rate up to 1300°C: 150°C / hour;

[0031] ③Insulation at 1300°C for 5 hours;

[0032] ④Cooling rate from 1300°C to 1200°C: 100°C / hour;

[0033] ⑤Insulate at 1200°C for 30 minutes;

[0034] ⑥Cooling rate from 1200°C to 1100°C: 100°C / hour;

[0035] ⑦Cooling rate from 1100°C to 600°C: 200°C / hour;

[0036] ⑧Cooling rate below 600°C: 150°C / hour;

[0037] In this example, the oxygen content is adjusted according to the theory of equilibrium oxygen partial pressure, and the difference from the prior art is that there is an additional heat preservation step 5, and the oxygen content in this step also remains unchanged.

Embodiment 2

[0038] Embodiment 2: The temperature distribution is the same as that of Embodiment 1. In order to move the lowest temperature of power consumption to a low temperature, the overall oxygen content is lower than that of Embodiment 1, as shown in the curve in FIG. 3 .

Embodiment 3

[0039] Implementation 3: The temperature distribution is also the same as that of Example 1. In order to move the lowest temperature of power consumption to a higher temperature, the overall oxygen content is higher than that of Example 1, as shown in the curve in FIG. 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com