Multifunctional measuring method and device for flexible material bending fatigue

A flexible material and measurement method technology, applied in the direction of measurement device, analysis material, material impedance, etc., to achieve the effect of easy installation and replacement, increased functions and control conditions, and reasonable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Bending fatigue test results of single fiber under constant load

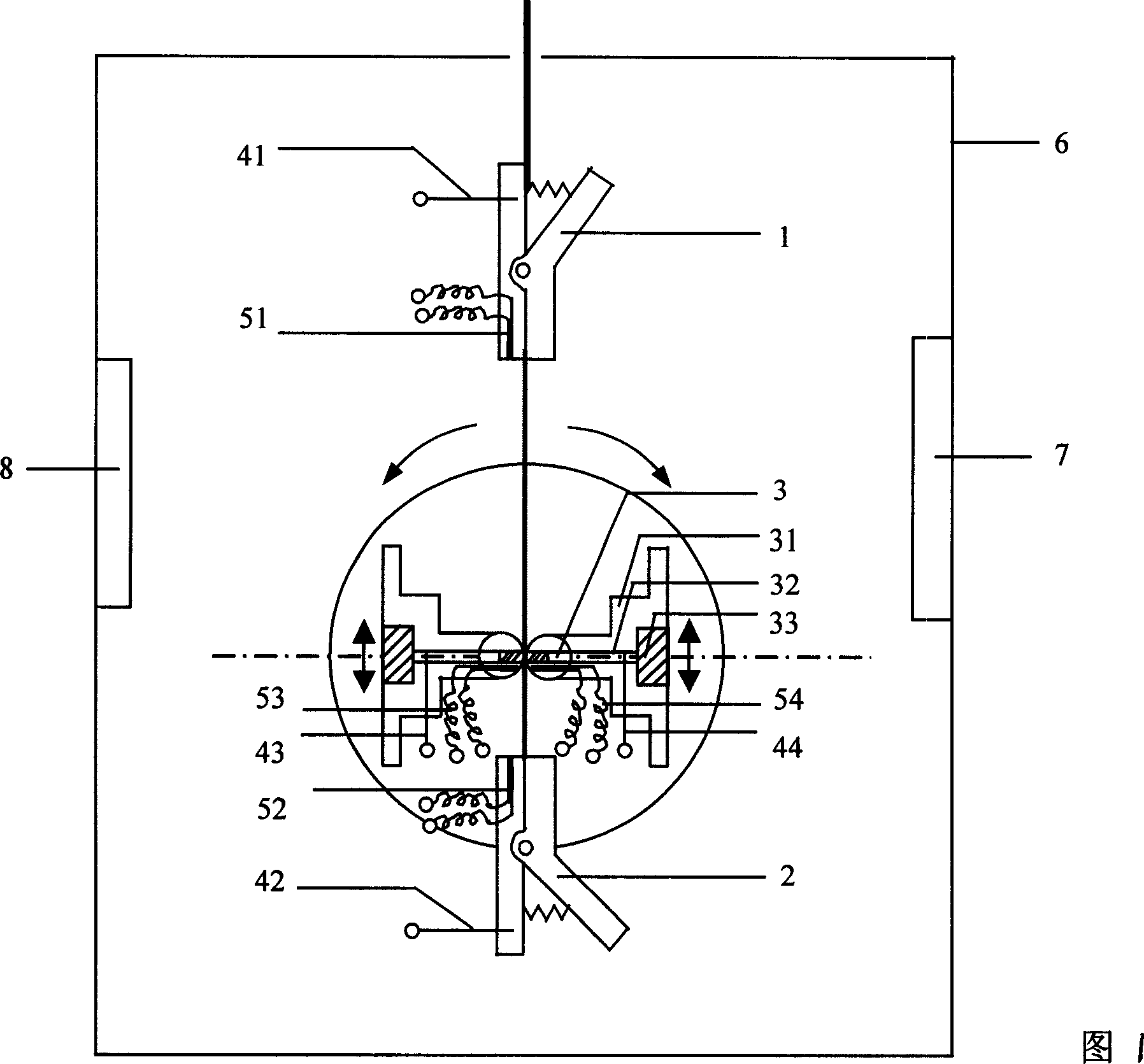

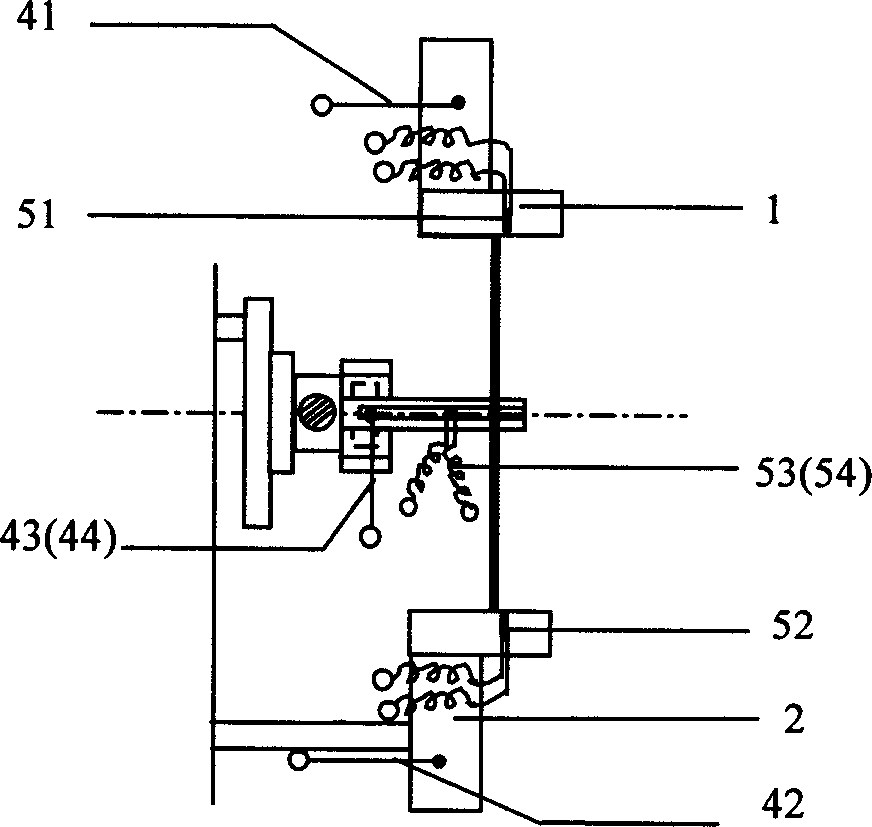

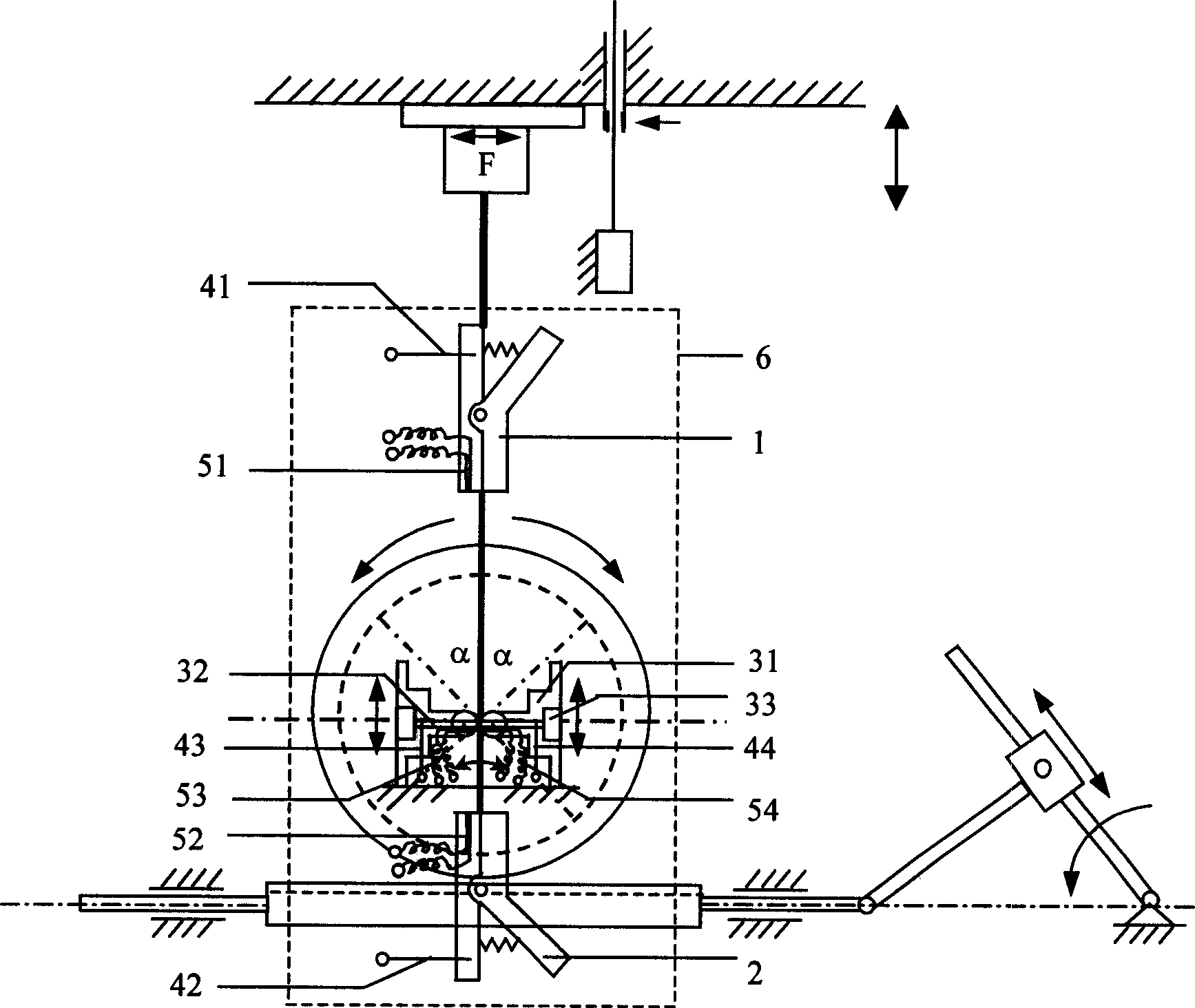

[0033] Clamp the aramid fiber sample between the upper clamp 1 and the lower clamp 2, and pass through the double positioning pin 3 of the positioning holder. Adopt the device of the present invention that has temperature control chamber cover 6, see accompanying drawing 1 and attached image 3 . Perform fatigue life measurements.

[0034] The pretension taken is 3cN, the bending angle α=35°, and the fatigue life test results of aramid (Twaron 2000) fibers under different temperature conditions are:

[0035] Temperature (℃) Fatigue life (times)

[0036] 0 9100 9004 8485 8846 8753

[0037] 40 9780 9320 9516 9627 9871

[0038] 100 9805 9765 9569 9638 9721

[0039]Obviously, it can be seen from the data in the table that different ambient temperatures have different fatigue resistance. It can be found that the fatigue resistance is the worst at 0°C, because the material is ha...

Embodiment 2

[0040] Example 2: Resistance measurement in bending fatigue

[0041] Using the same device as in Example 1, the wool fiber sample was clamped between the upper chuck 1 and the lower chuck 2, and passed through the double positioning pins 3 of the positioning holder. Test the resistance between 41 and 42 and the resistance between 43 and 44 respectively, and change the temperature inside the temperature-controlled chamber cover. Test the resistance change of the test sample between the upper and lower clamps and between the double positioning pins.

[0042] Resistance measurement results of wool with a moisture content of 15%

[0043] Temperature (°C) Resistance R between 41-42 (×10 8 Ω) Resistance R between 43-44 (×10 5 Ω)

[0044] 63.12 60.91 64.65 69.82 59.49 60.05 62.38 59.89 62.74 66.85

[0045] 20

[0046] 10.15 11.22 10.81 9.79 9.27 11.26 10.29 10.49 9.56 9.78

[0047] 40

[0048] 1.60 1.76 1.62 1....

Embodiment 3

[0051] Embodiment 3: Measurement of temperature difference between 4 points and thermal conductivity

[0052] Using the same device as in Example 1, the polyester film sample was clamped between the upper chuck 1 and the lower chuck 2, and passed through the double positioning pins 3 of the positioning holder. Test the temperature difference between 53-54 or the refrigeration or heating power to maintain this temperature difference to obtain the material’s lateral thermal conductivity and heat flow rate. The ambient temperature is controlled at 20±1°C by the temperature control chamber cover 6; Refrigeration, constant temperature or heating at 54 places with double positioning pins, the measured thermal conductivity in the thickness direction of the polyester film under different temperature differences is as follows:

[0053] ambient temperature

[0054] Obviously, it can be seen from the data in the table that the temperature difference has an influence on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com