High-density polyethylene steel reinforced winded pipe spigot-and-socket connector

A high-density polyethylene and connecting device technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc. The effect of welding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

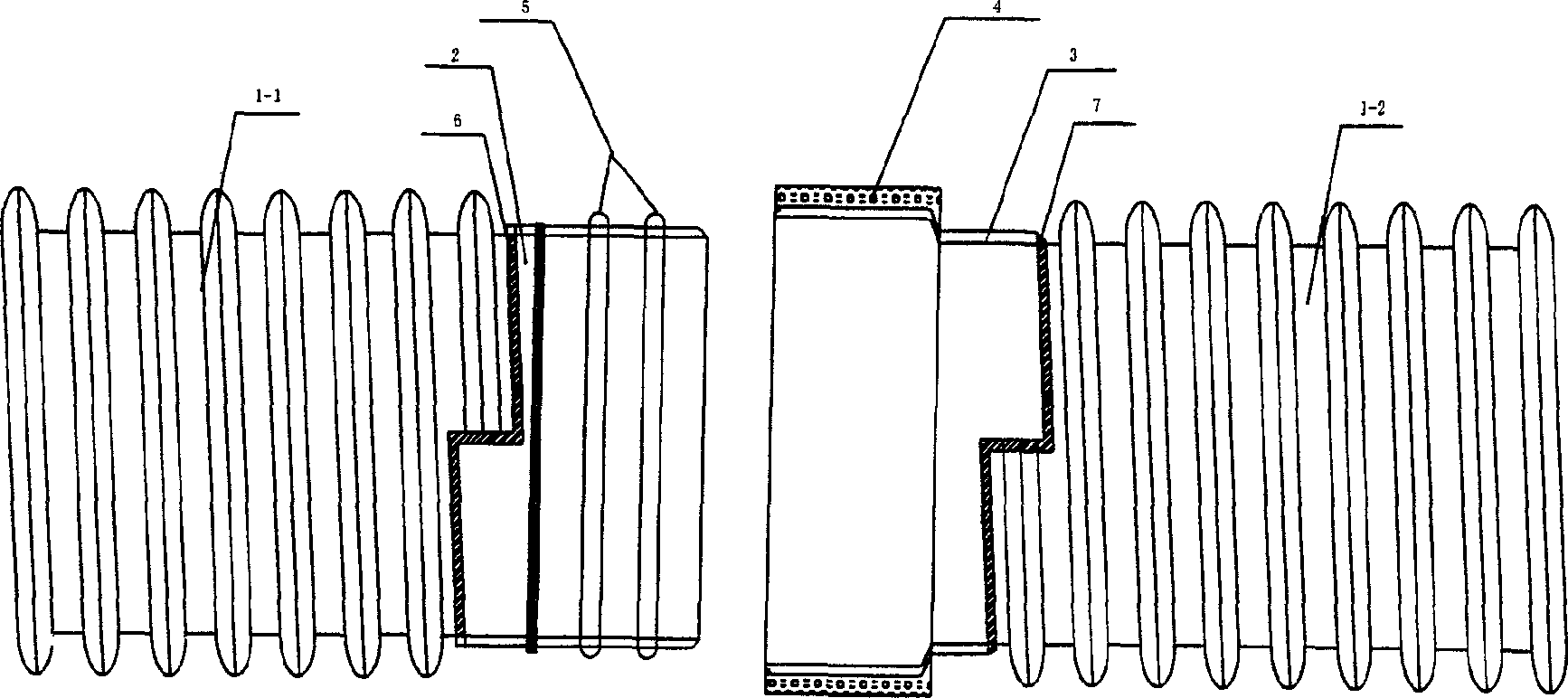

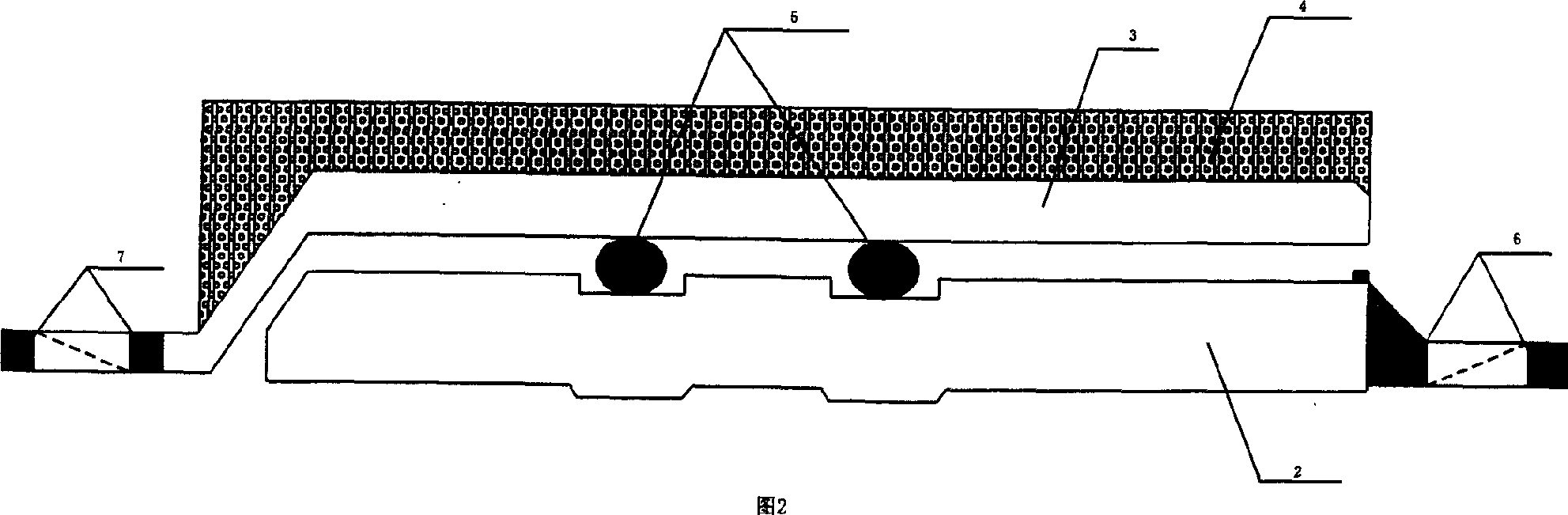

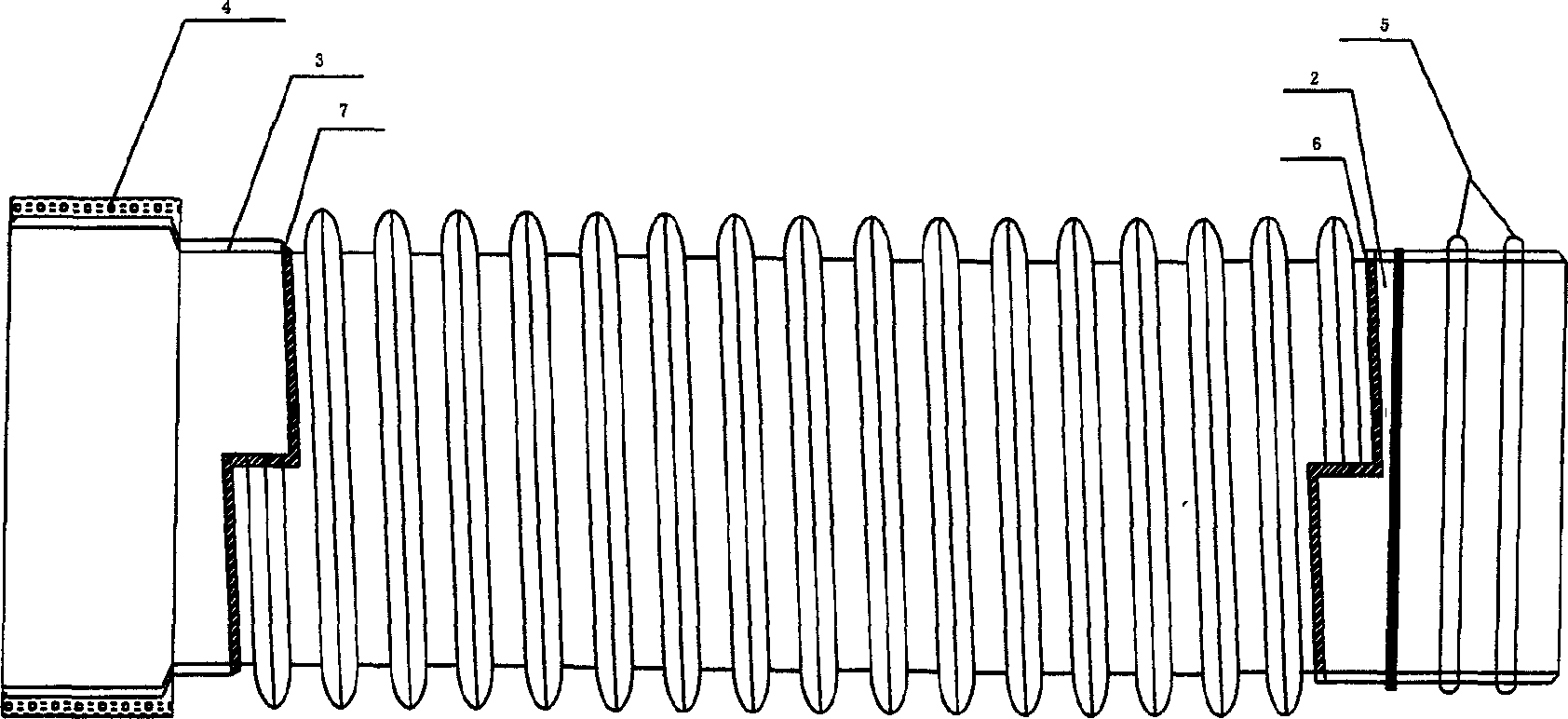

[0048] Example 2: Please refer to Figure 7 Connecting socket (b): In this embodiment, when the connecting socket 2 is inserted in place, the inner wall of the connecting socket 3 corresponding to the groove 2-2 opens an outer convex groove 3-3, and the outer wall has an outer convex rib 3-2 On the one hand, the protruding ribs can enhance the ring stiffness of the connecting socket 3, and on the other hand, it can position the FRP casing 4 fixed on the outer periphery. The schematic diagram of the socket assembly section (2) please refer to Figure 8 Shown, all the other implementation methods are identical with example 1.

Embodiment 3

[0049] Embodiment 3: This embodiment only changes the structure of the rubber sealing ring 5 in Embodiment 2, and the Figure 6 The shown "O" type sealing ring 5 is changed to Figure 9 shown (Rectangular section) type rubber sealing ring 5-1, all the other implementation methods are the same as example 2.

Embodiment 4

[0050]Example 4: Please refer to Figure 10 Schematic diagram of socket assembly section (3): In this embodiment, on the basis of Example 2, a small air hole 8 is opened on the connection socket between the two rubber rings. After the socketing is completed, it can be inflated, and the air tightness test can be carried out. After the specified requirements are met, the small hole can be blocked with a polyethylene rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com