Polysiloxane sealing material with modified surface and preparation thereof

A polyorganosiloxane and sealing material technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of complex synthesis, increased cost of polyorganosiloxane sealing materials, and many steps, and achieve simple preparation process , Strong adhesion and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

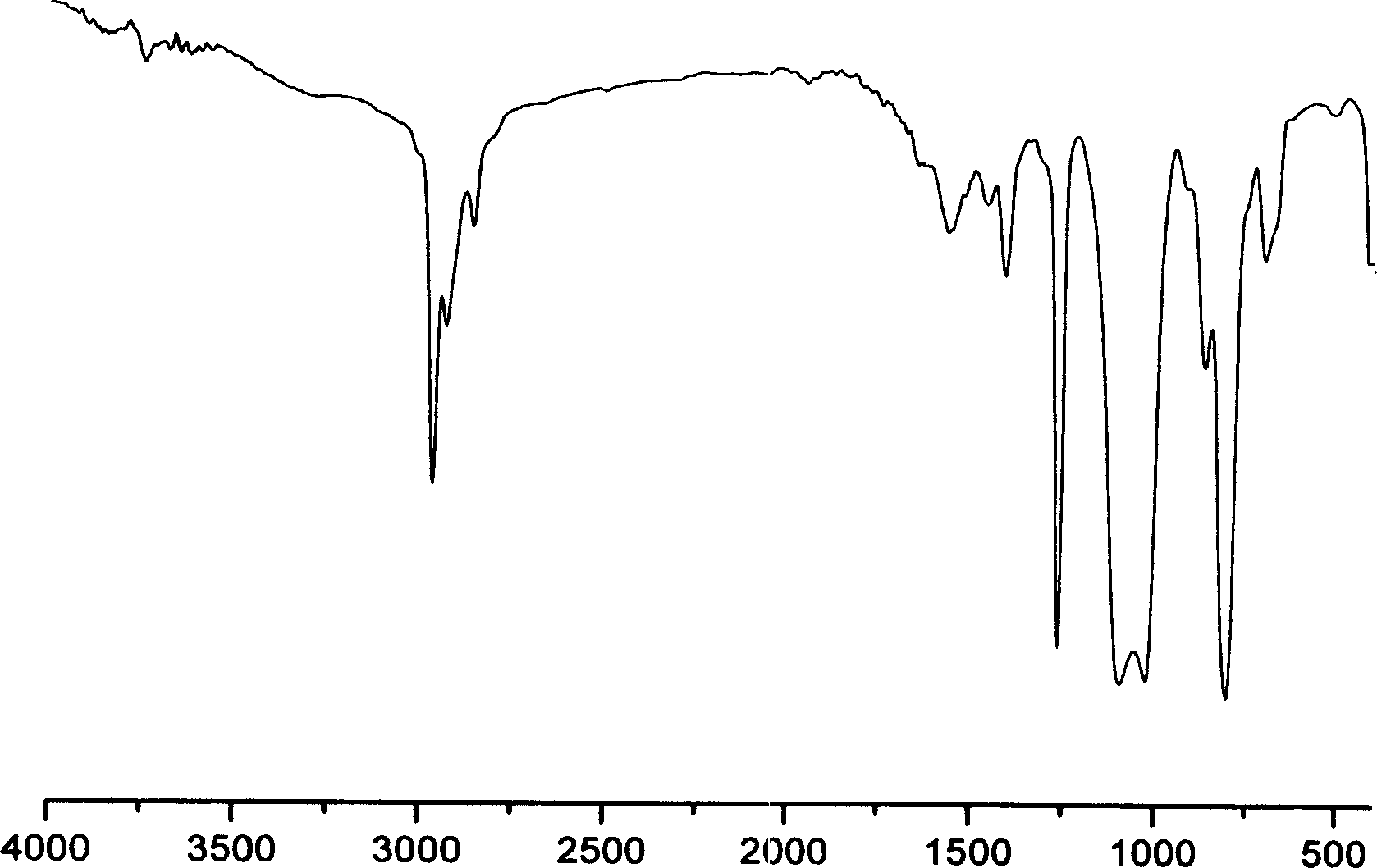

[0035] Introduce 20.6 grams of N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane and 50 milliliters of toluene into a three-necked flask equipped with a stirrer, and the moisture in the mixture gradually dissolves by azeotroping for 30 minutes. Removed, and then 28.8 grams of oleic acid was added dropwise with a dropping funnel. The set temperature is 100°C, and dry nitrogen gas is fed into it. After three hours of reaction, the mixture is sampled and analyzed by infrared absorption spectrum (IR), and it is found that the characteristic absorption peak of the carboxyl group disappears, and a new amido group absorption peak is formed. The reaction is thus complete. The IR spectrum is shown in figure 1 . The brown transparent liquid obtained by heating and distilling low boilers is the viscosity-increasing additive of the present invention.

[0036] Mix 100 parts (viscosity of 20000mPa.s) of hydroxyl-terminated polydimethylsiloxane and 80 parts of nano-active calcium carbonat...

Embodiment 2

[0047] 0.5 g of the thickening additive synthesized in Example 1 was mixed with 10 g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 3000 mPa.s. The appearance of the resulting mixture was visually evaluated: the mixture was white turbid but slightly transparent, and when the mixture was left at room temperature for 3 days, its appearance was almost completely unchanged from the new mixture.

Embodiment 3

[0052] 22.2 grams of N-β-aminoethyl-γ-aminopropyltrimethoxysilane and 50 milliliters of toluene were imported into a three-necked flask equipped with a stirrer, and the moisture in the mixture was gradually removed by azeotropic 30 minutes, and then 27.8 g of oleic acid was added dropwise with a dropping funnel. The temperature is set at 100° C., and dry nitrogen is passed through. After reacting for three hours, the viscosity-increasing additive of the present invention is obtained by heating and distilling low boilers.

[0053] Mix 100 parts (viscosity: 5000mPa.s) of hydroxyl-terminated polydimethylsiloxane and 100 parts of nano-active calcium carbonate treated with stearic acid under vacuum-tight condition of 0.1-1kPa, and then add 3 parts of tackifying additives, 6 parts of methyltrimethoxysilane, 0.2 parts of tetrabutyl titanate. Mix evenly, and vacuum remove air bubbles to obtain the surface-modifiable polyorganosiloxane sealing material of the present invention.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com