Electrochemical regenerator and regenerating method for activated carbon

A regeneration device and activated carbon technology, which is applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of difficult oxidation and degradation of organic matter, incomplete regeneration of activated carbon, and impact on the economy of activated carbon, etc., to improve the treatment effect, Thorough regeneration and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

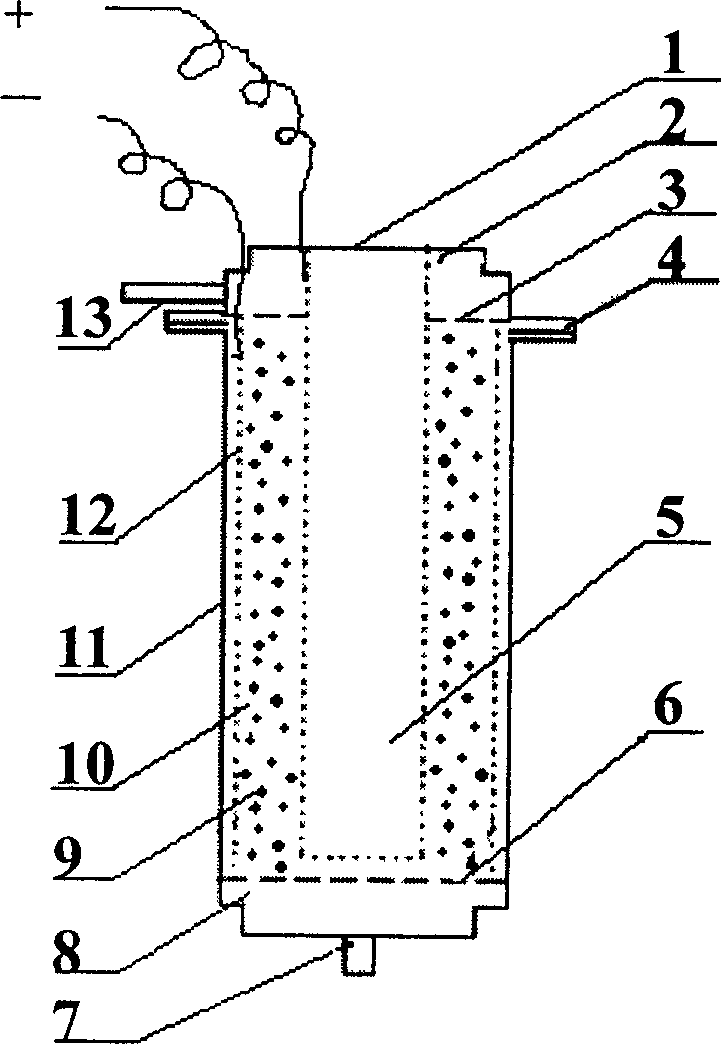

[0024] Embodiment 1: activated carbon electrochemical regeneration

[0025] A Shanghai activated carbon (30 mesh) was first saturated with p-nitrophenol with an initial concentration of 500mg / L. 3g of saturated activated carbon is put into the electrochemical reaction chamber, the anode in the electrochemical reaction chamber is a lead dioxide ceramic tube electrode modified by fluororesin, and the cathode is a stainless steel mesh. Using 5g / L NaCl as the electrolyte, and adjusting the pH to 3, the activated carbon is in a fluidized state by controlling the current to 0.5A and the liquid flow rate to 3.25L / min. Tests have shown that the regeneration efficiency of activated carbon can reach 92% after electrochemical treatment for 1.5 hours. As the current increases, the regeneration efficiency of activated carbon increases. As the liquid flow rate increases, the activated carbon regeneration efficiency also increases. When the activated carbon is in the fixed bed state, the ...

Embodiment 2

[0026] Embodiment 2: activated carbon electrochemical regeneration

[0027] 3 g of activated carbon saturated with adsorption in Example 1 was used to put into the electrochemical reaction chamber, the anode in the electrochemical reaction chamber was a tin dioxide electrode, and the cathode was still a stainless steel mesh. With 10g / L Na 2 SO 4As an electrolyte, adjust the pH to 3, control the current to 1.0A, and the liquid flow rate to 3.75L / min, so that the activated carbon is in a fluidized state. The regeneration efficiency of activated carbon after treatment for 1.0 hr was 83.7%.

Embodiment 3

[0028] Embodiment 3: Fluidized bed electrochemical reactor treats organic waste water

[0029] Using the device of Example 1, under the same activated carbon dosage (without adsorption), current and liquid flow rate, etc., the p-nitrophenol wastewater with an initial concentration of 150 mg / L was treated, and p-nitrophenol was almost completely removed after 20 minutes of treatment. , and the removal rate of chemical oxygen demand (COD) can reach more than 85% within 2 hours. And without changing the activated carbon for 6 consecutive times, the treatment efficiency did not decrease significantly, indicating that the activated carbon was effectively regenerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com