Cutter apparatus for flat plate building material

A technology for building materials and cutting tools, applied in sawing machines, stone processing tools, wood processing appliances, etc., can solve the problems of power cost, complex structure, and large installation space requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

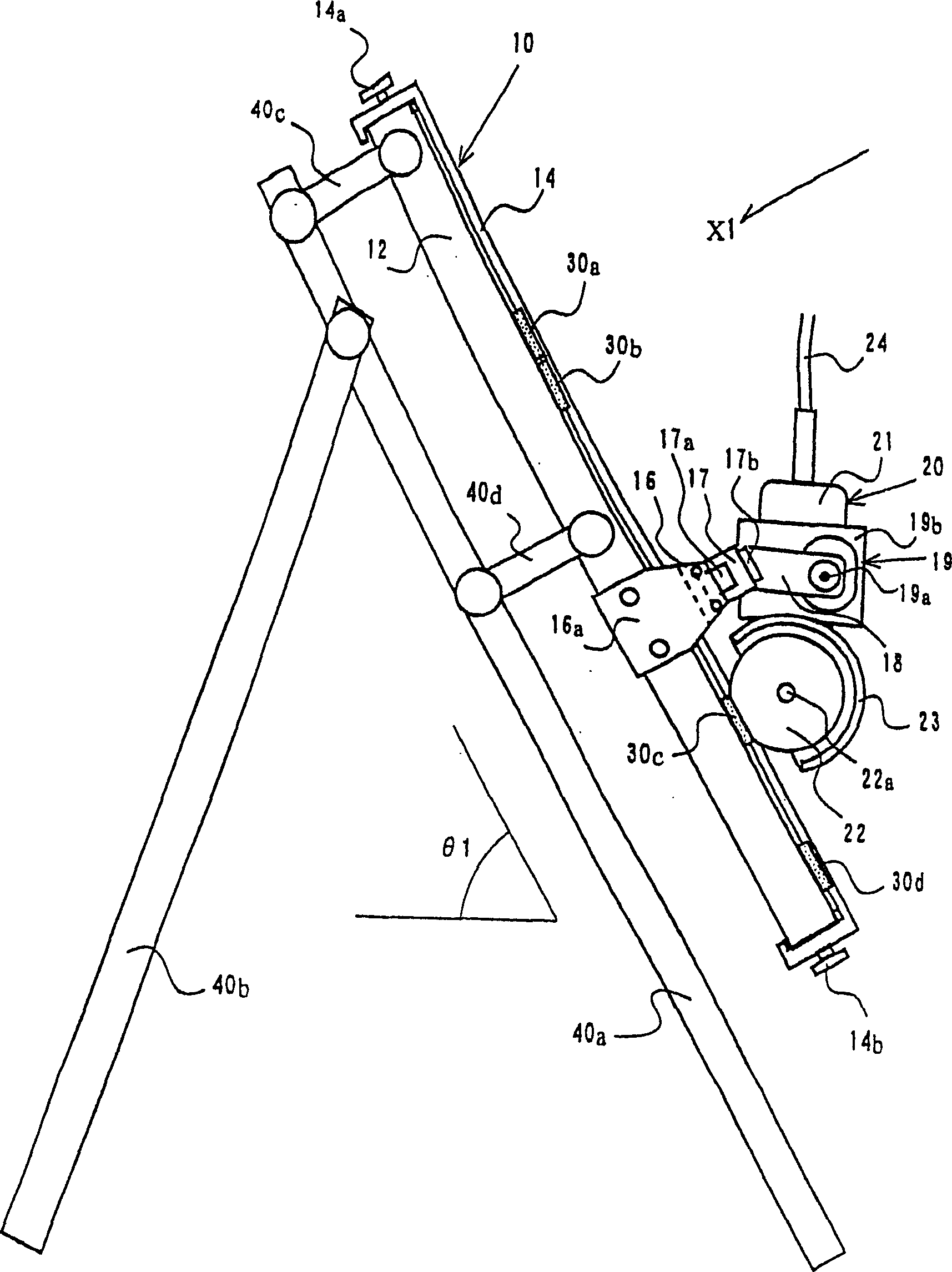

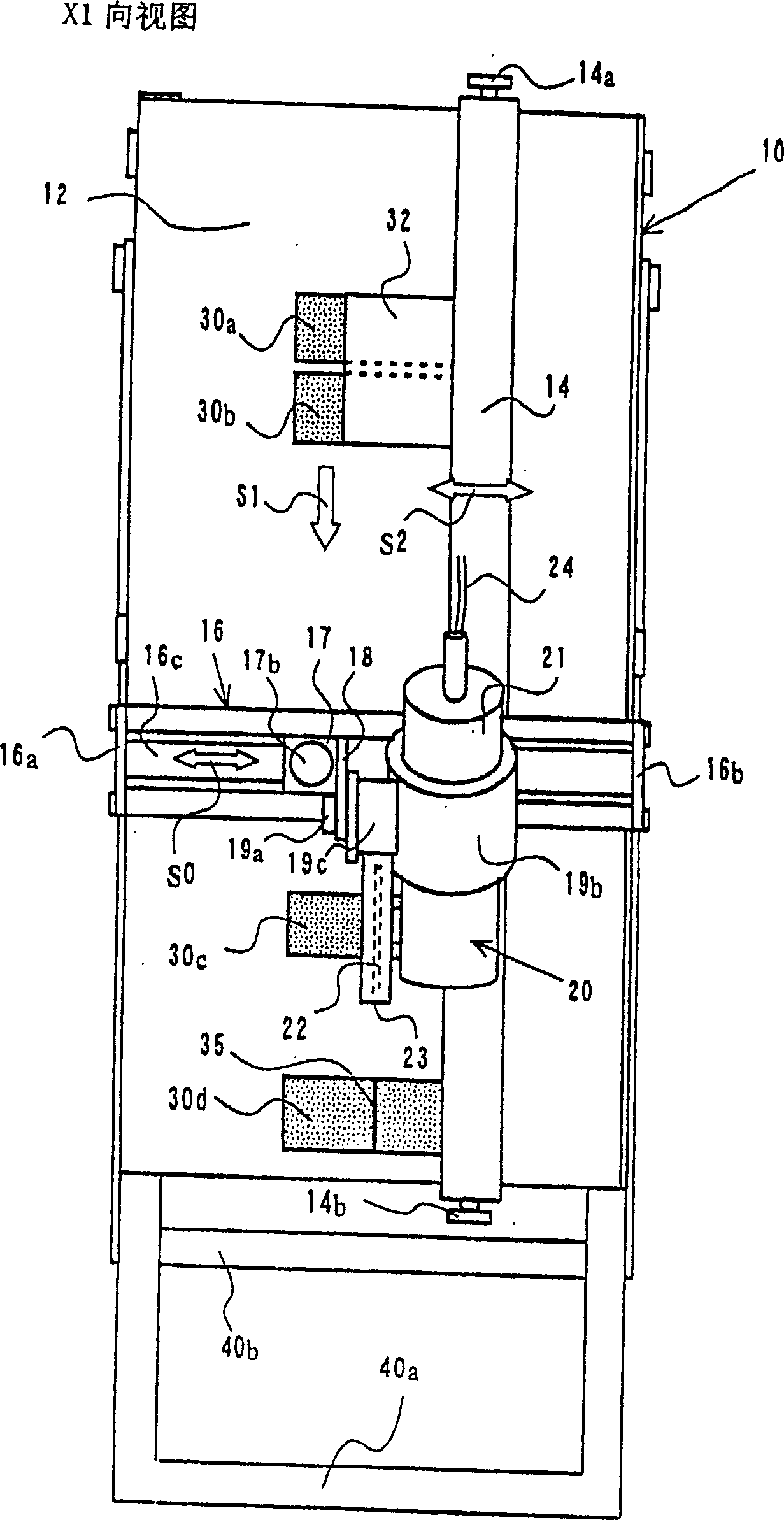

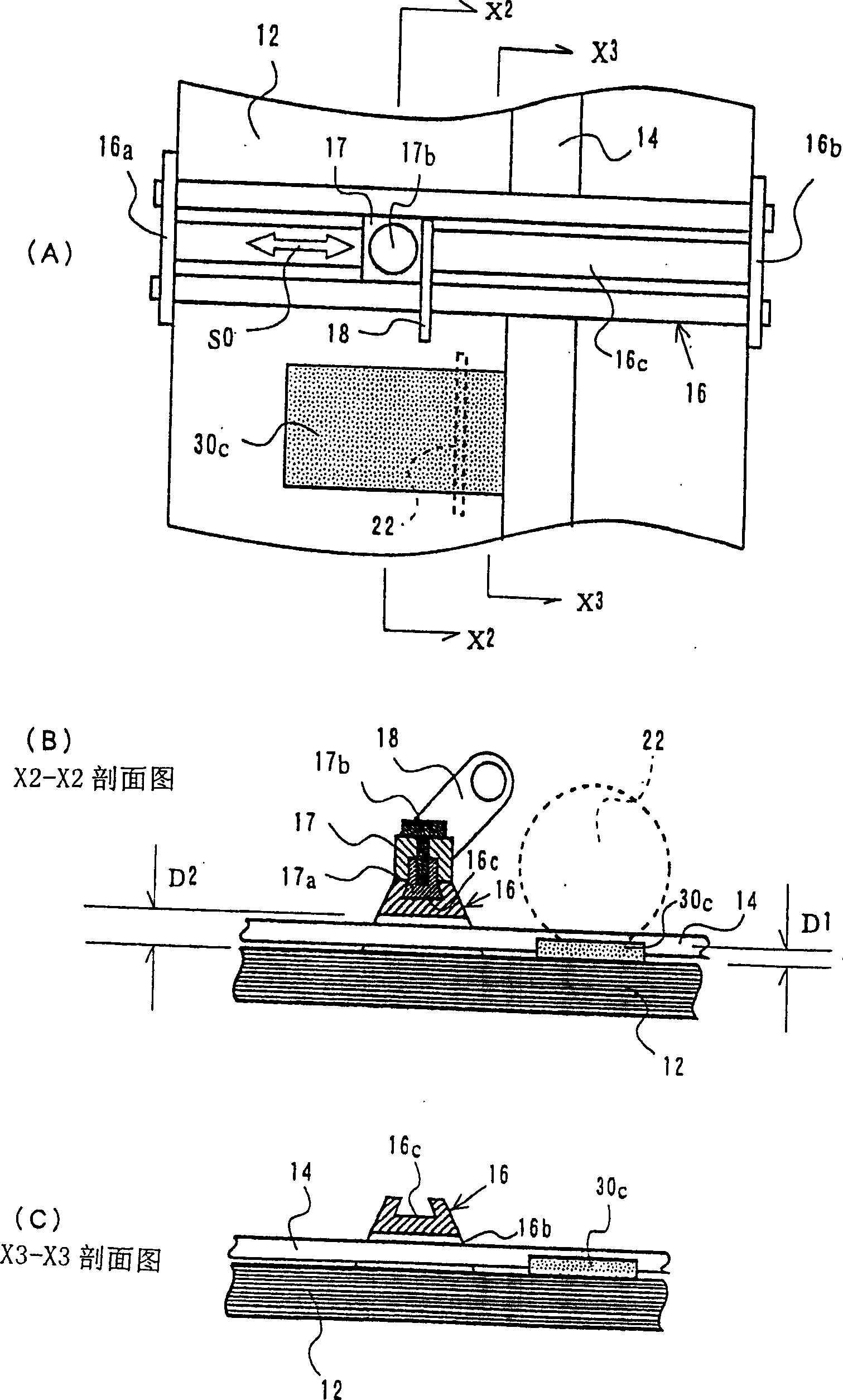

[0072] figure 1 It is a side view of a cutter device for flat building materials according to an embodiment of the present invention. figure 2 for along figure 1 The arrow X1 shown is a view in the X1 direction of the cutter device for flat building materials. The following will describe the case where the flat building material is ceramic tiles.

[0073] According to the cutter device 10 for flat building materials of the present invention, there is a cutter 20 provided with an inclined table 12 provided with an inclined surface and a rotary blade 22 for cutting the ceramic tiles 30a-30d that slide down from the inclined surface, and for setting the rotary blade 22 The tool fixing method of the fixed tool 20 at a certain height from the above-mentioned slope. The inclination angle of the slope is represented by θ1.

[0074] For the sake of safety, a rotary blade cover 23 is provided to cover the rotary blade 22 safely. A motor and the like for driving the rotary blade 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com