Arc-control device for circuit breaker

A technology of arc extinguishing device and circuit breaker, which is applied in the direction of circuit breaker components, etc., which can solve the problems of wall damage, only one gas outlet, unfavorable metal free gas escape quickly, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

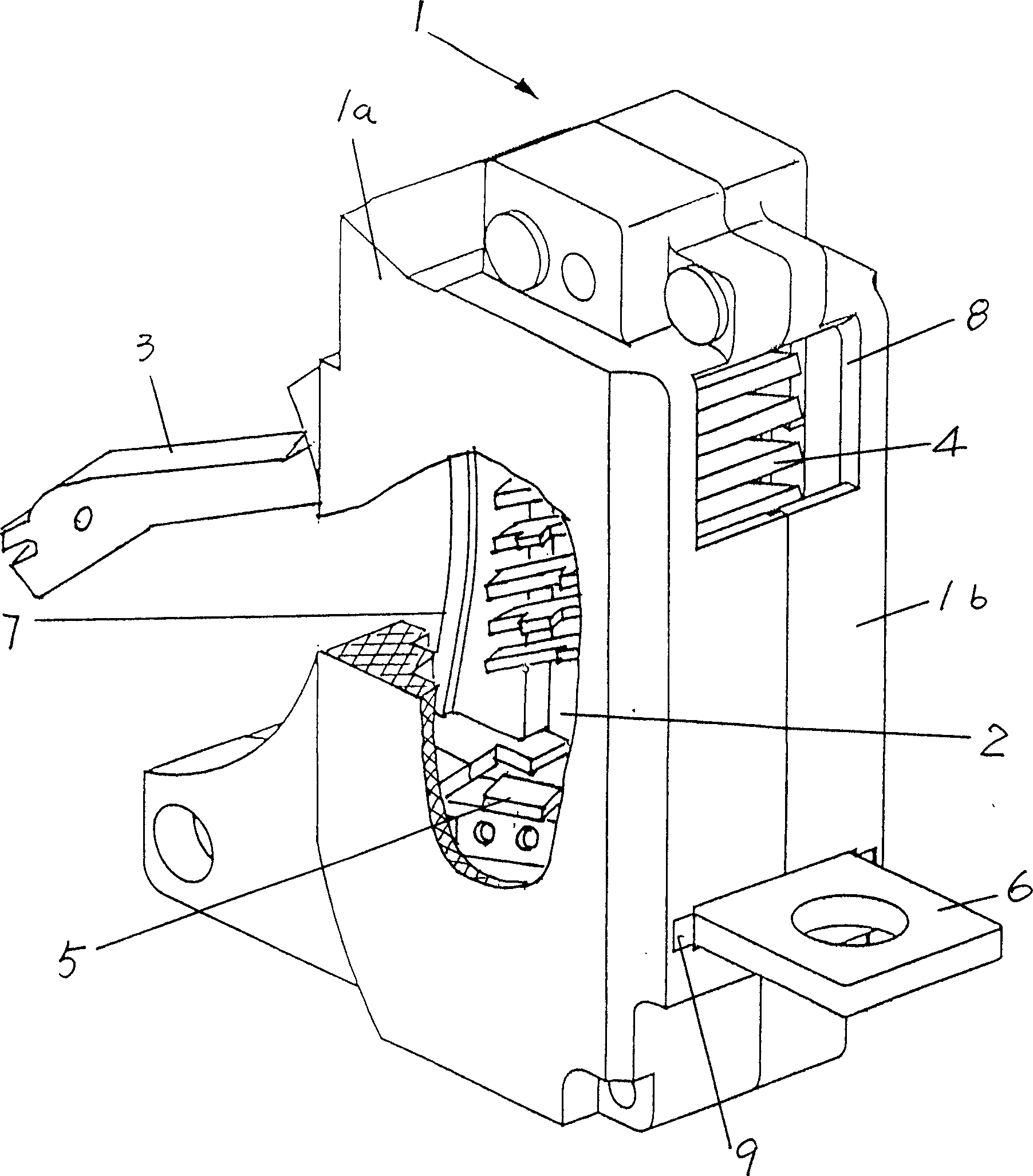

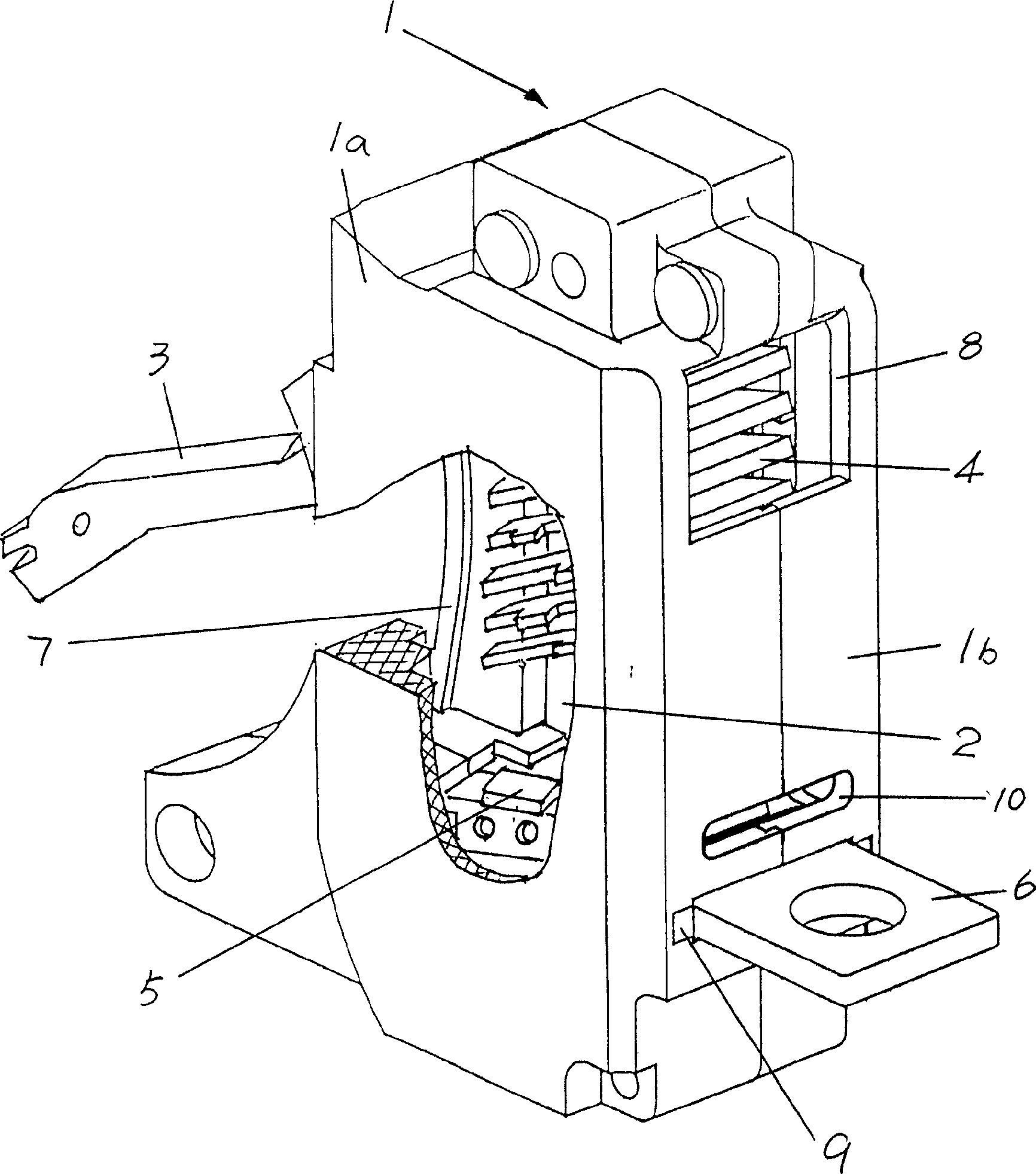

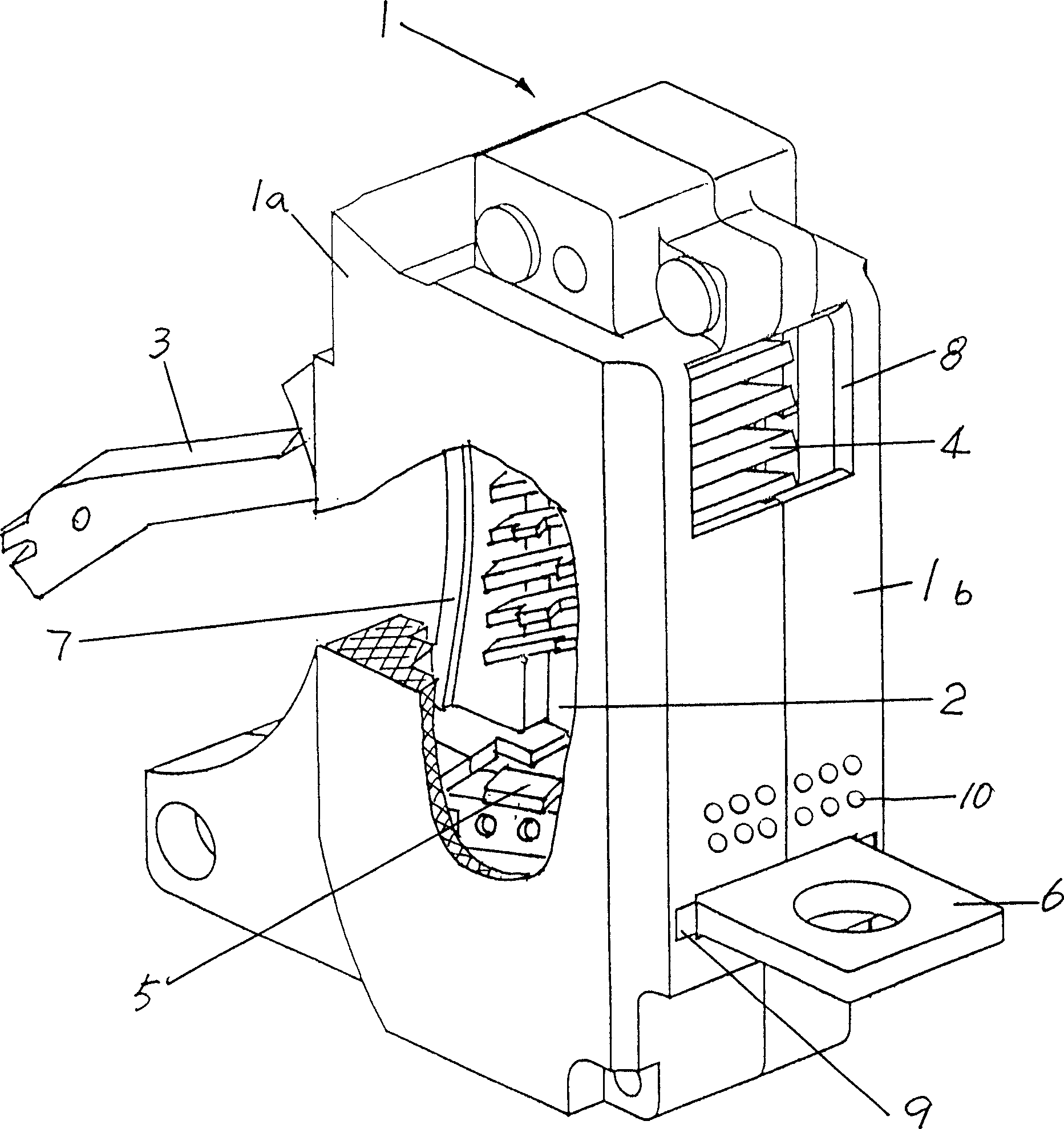

[0015] Such as figure 2 As shown, on the back of the housing 1 and between the second and third openings 8 and 9, a fourth opening 10 is added, which is mainly used to quickly escape the metal free gas. The fourth opening 10 is as close as possible to the metal free gas. The accumulation area, that is, the contact area where the arc root is located. Since the arc root is the part where a large amount of contact metal free gas is generated and enters the arc channel, the ionization effect is strong and the concentration of conductive ions is high. Therefore, the air flow acting on the arc root is important for the arc to increase the arc column resistance and improve the breaking performance. effect. However, the solution of the present invention can quickly discharge metal free gas and adjust the gas flow direction at the arc root through the fourth opening 10, and the fourth opening 10 is set as a long and thin opening to avoid the pressure drop in the arc extinguishing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com