Symmetrically balanced chain type oil pumping unit

A symmetrical balance and pumping unit technology, applied in the direction of belt/chain/gear, mechanical equipment, mining fluid, etc., can solve problems such as broken chain, uneven force, small inertial load, etc., and reduce the failure rate of the whole machine , Reduce the number of shutdowns for maintenance, and the effect of reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

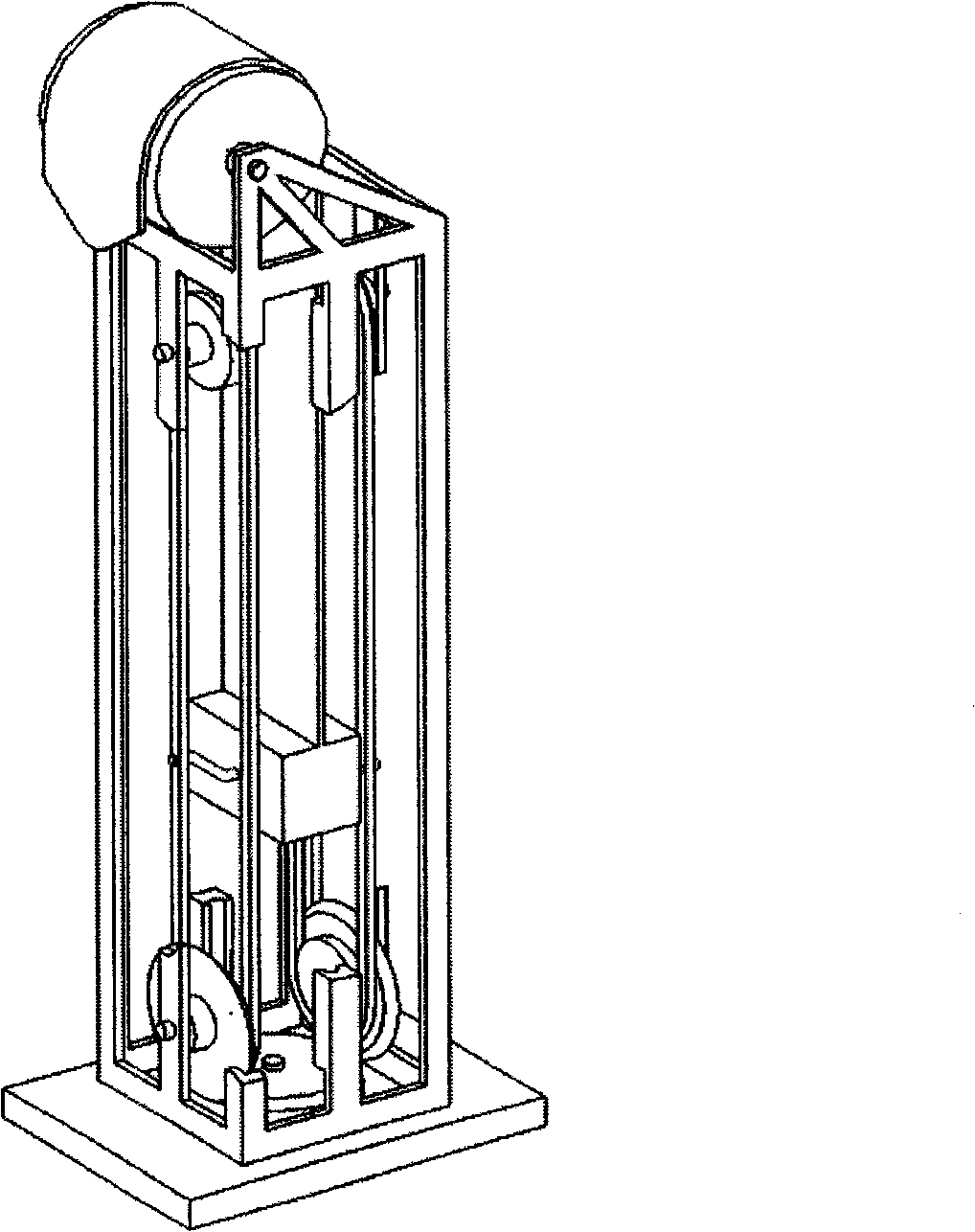

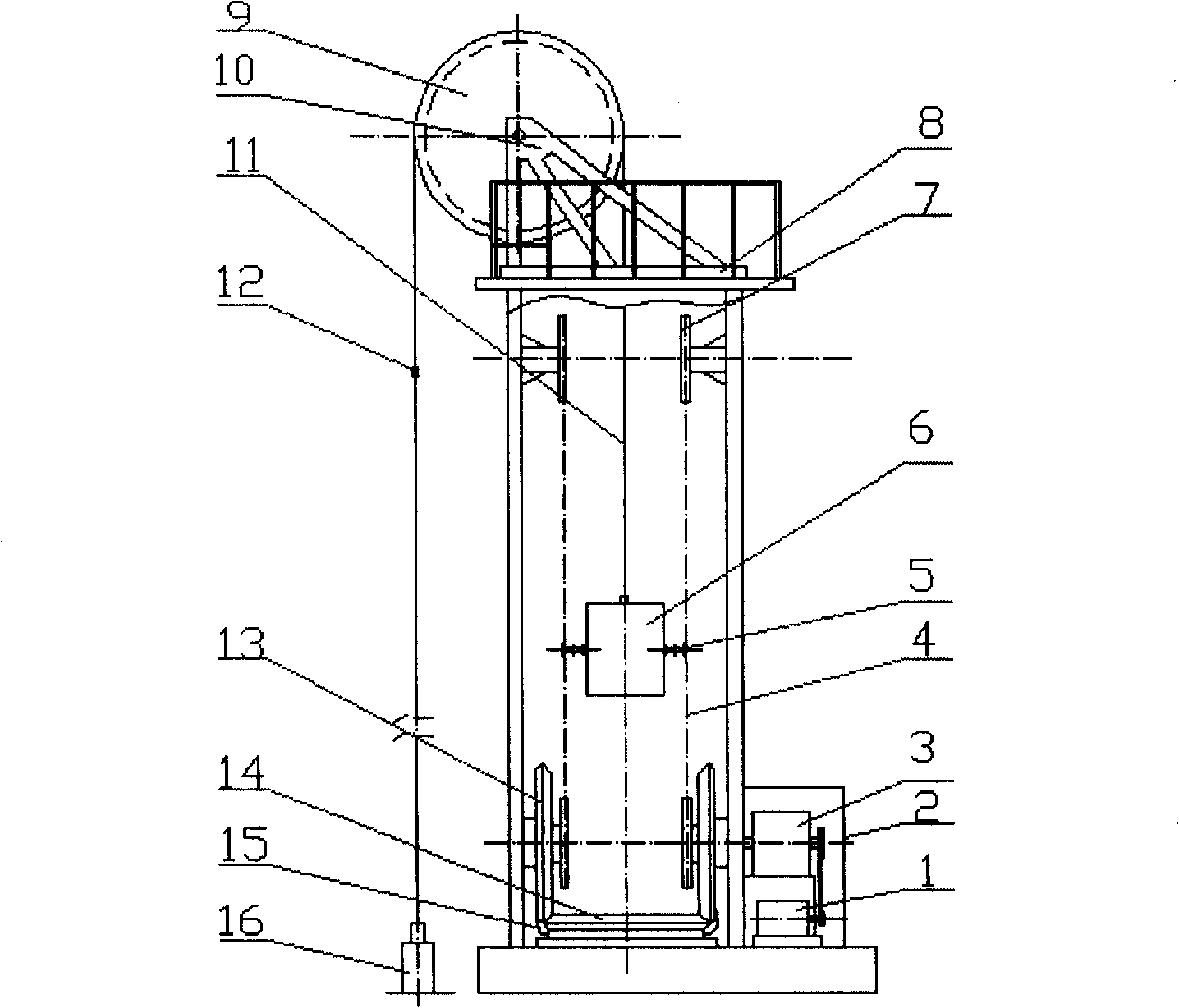

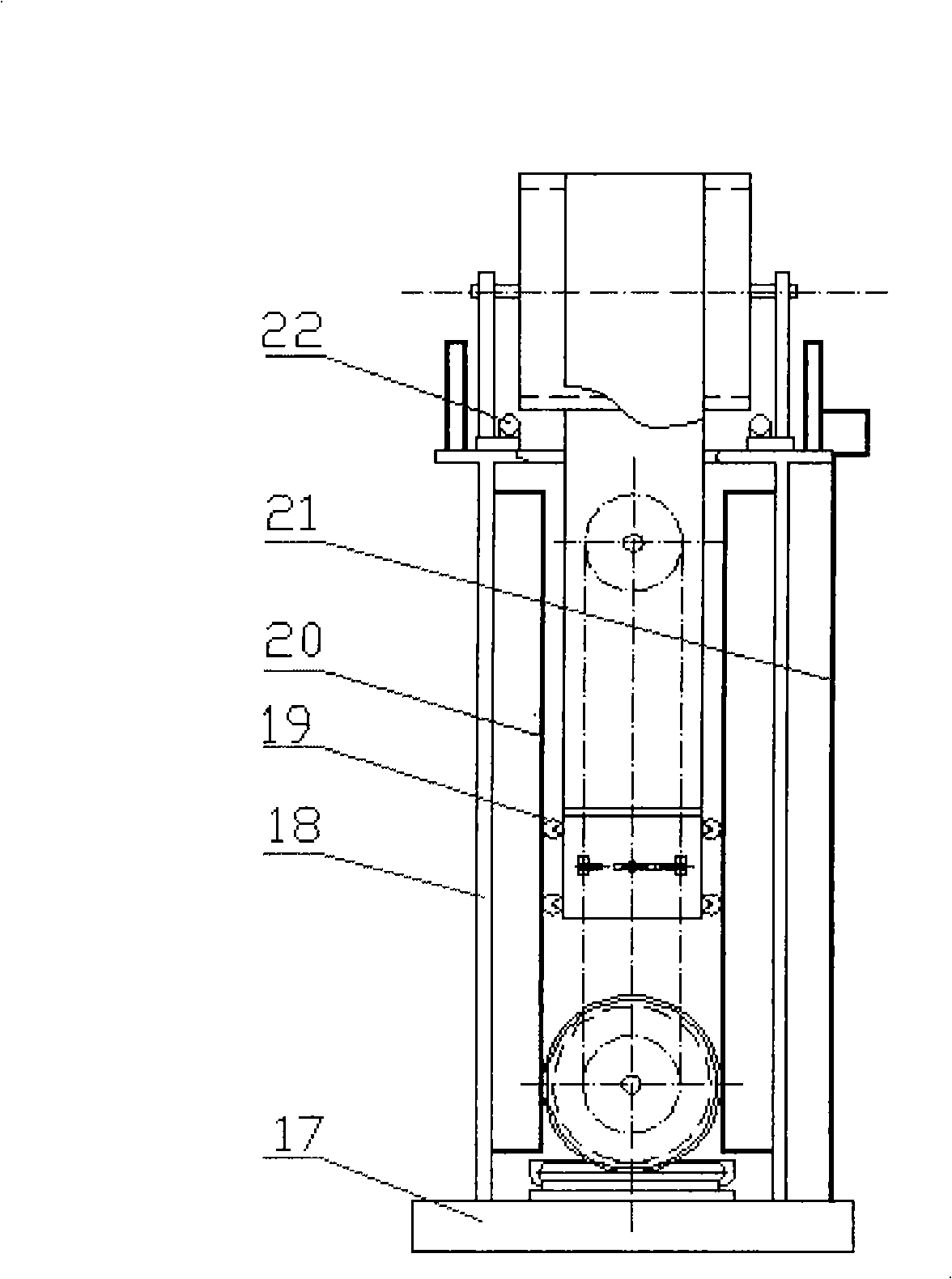

[0013] As shown in accompanying drawing 1 or Fig. 2 or Fig. 3, frame 18 is fixed on the base 17 among the present invention, and sky wheel frame 10 is installed on the top of frame 18, and sky wheel 9 is installed on wheel frame 10, and sky wheel 9 winds There is a weight-suspension adhesive tape 11, and one end of the adhesive tape is connected to the counterweight box, and the other end is connected to the rope hanger 12. Drive sprocket assembly 13 is installed in the bottom of frame 18, and drive sprocket assembly 13 is as shown in Figure 5, is made of two drive sprockets on separate sides and disc-shaped bevel gear 14 that is installed in frame bottom, and drive The sprocket wheel is assembled coaxially by the sprocket wheel 25 and the bevel gear 24, and the disc-shaped bevel gear 14 at the bottom of the two bevel gears 24 meshes with each other to transmit power. A driven sprocket 7 is respectively equipped with on both sides, top of frame 18, and chain 4 is housed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com