Process for preparing isobutene from tertiary butanol

A technology for isobutene and tert-butanol, applied in the field of isobutene preparation from tert-butanol, can solve the problems of high equipment expenditure, high energy consumption, large equipment size, etc., and achieve the effect of reducing equipment size and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The process for the preparation of isobutene according to the invention, that is to use tertiary Cleavage of butanol to isobutene and water, subsequent separation of the reaction mixture into isobutene, by-products, water and at least one mixture of uncracked tert-butanol and water, characterized in that the reactor is operated at a pseudo-isothermal, wherein The temperature difference between the feed stream and the output stream (feed stream and product stream) is below 15K, preferably below 10K, particularly preferably below 5K, most preferably below 1K. The feed to the reactor consists of a fresh feed stream and one or more recycle streams comprising a mixture of uncracked tert-butanol and water, wherein the mass ratio of the fresh feed stream to the total amount of recycle streams is lower than 1:10, Preferably below 1:5, particularly preferably below 1:3. It is advantageous to use a plurality of reactors connected in series or in parallel, wherein preferably all ...

Embodiment 1

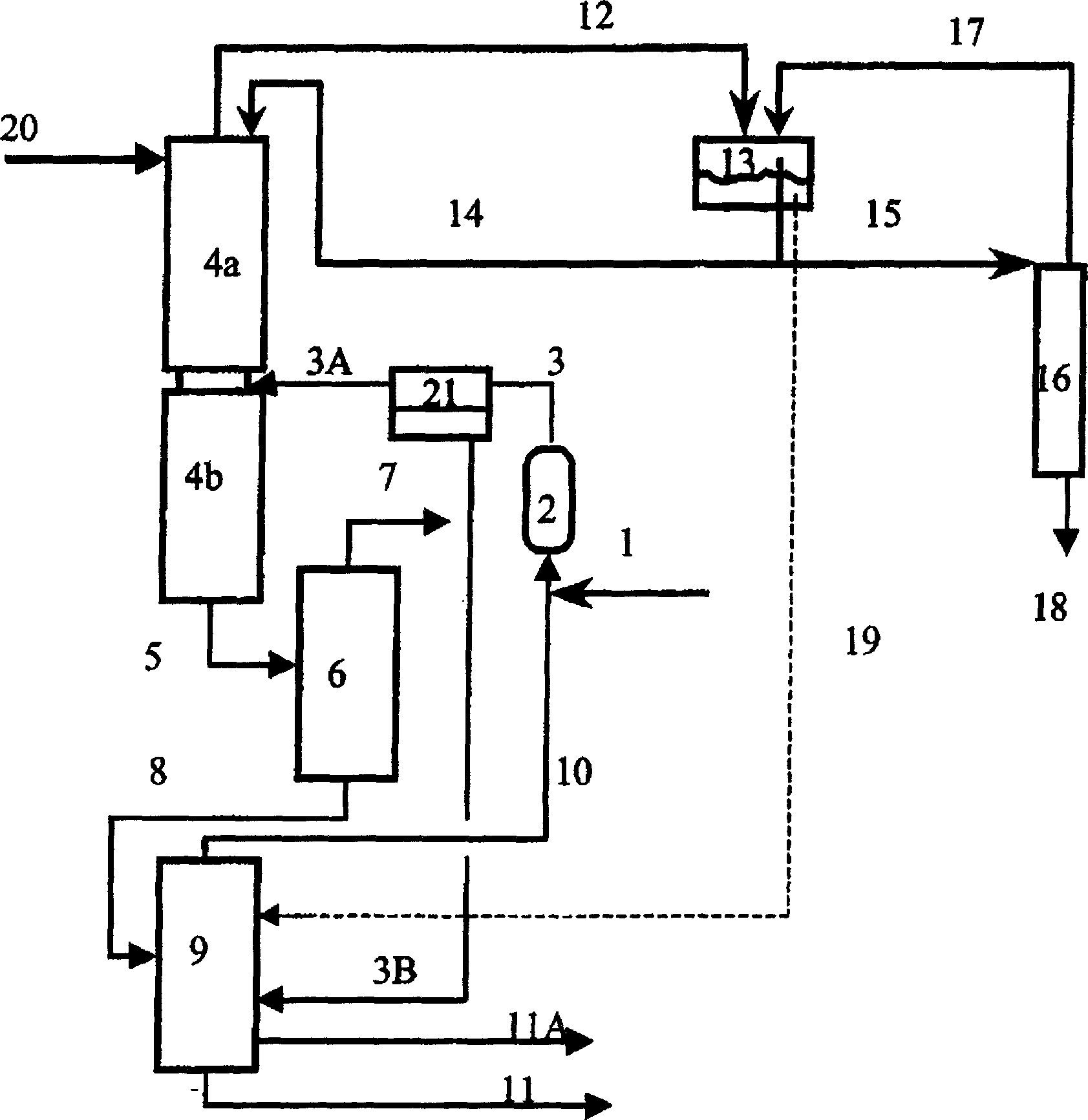

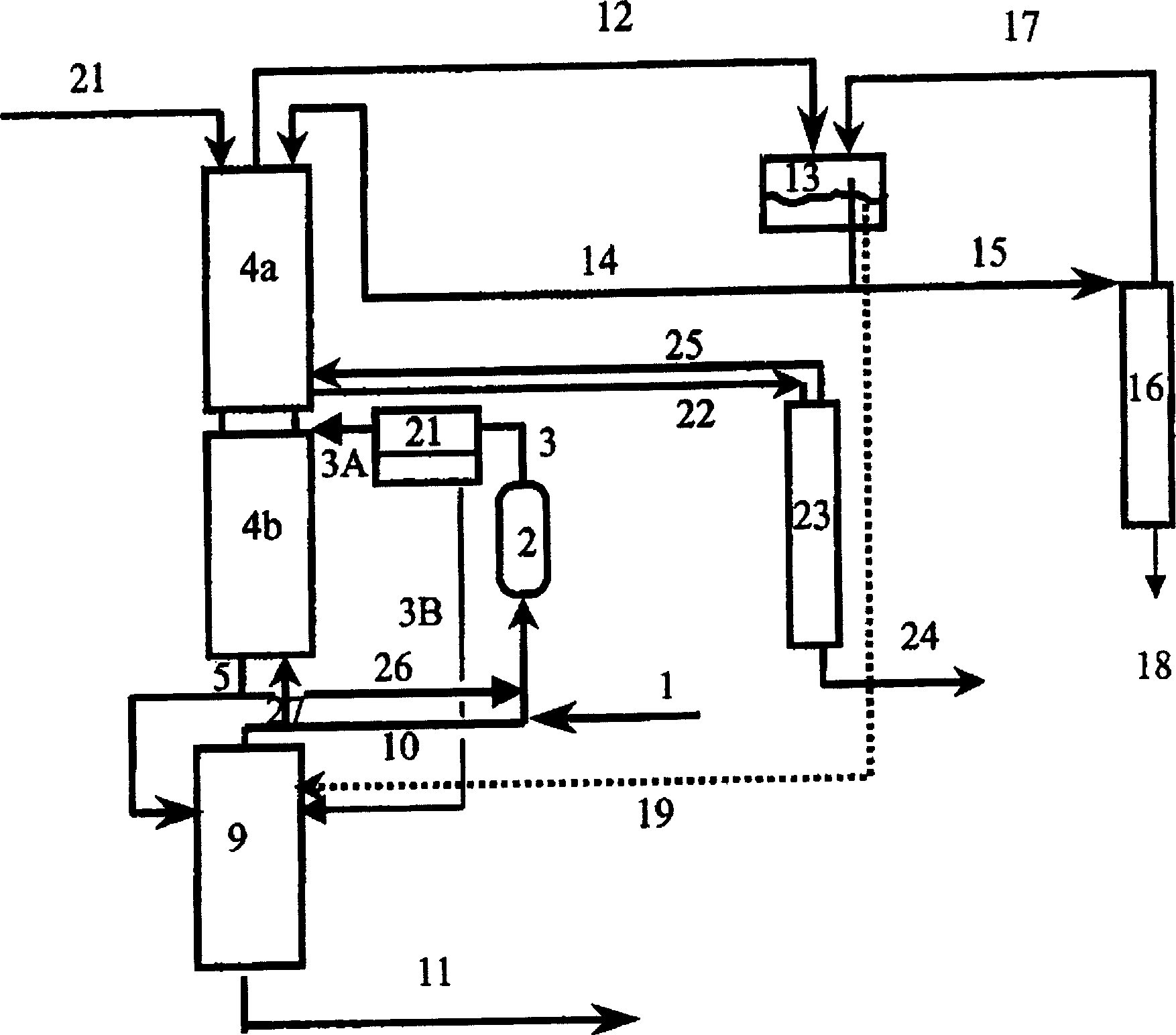

[0088] in the attached figure 1 And attached Figure 5 The production of isobutene in the shown plant is characterized in that no water separation using module ( 21 ) is carried out, so streams 3 and 3A have the same composition. Fresh water flow (20) and waste water flow (3B) are eliminated. The waste water stream (19) is discharged directly.

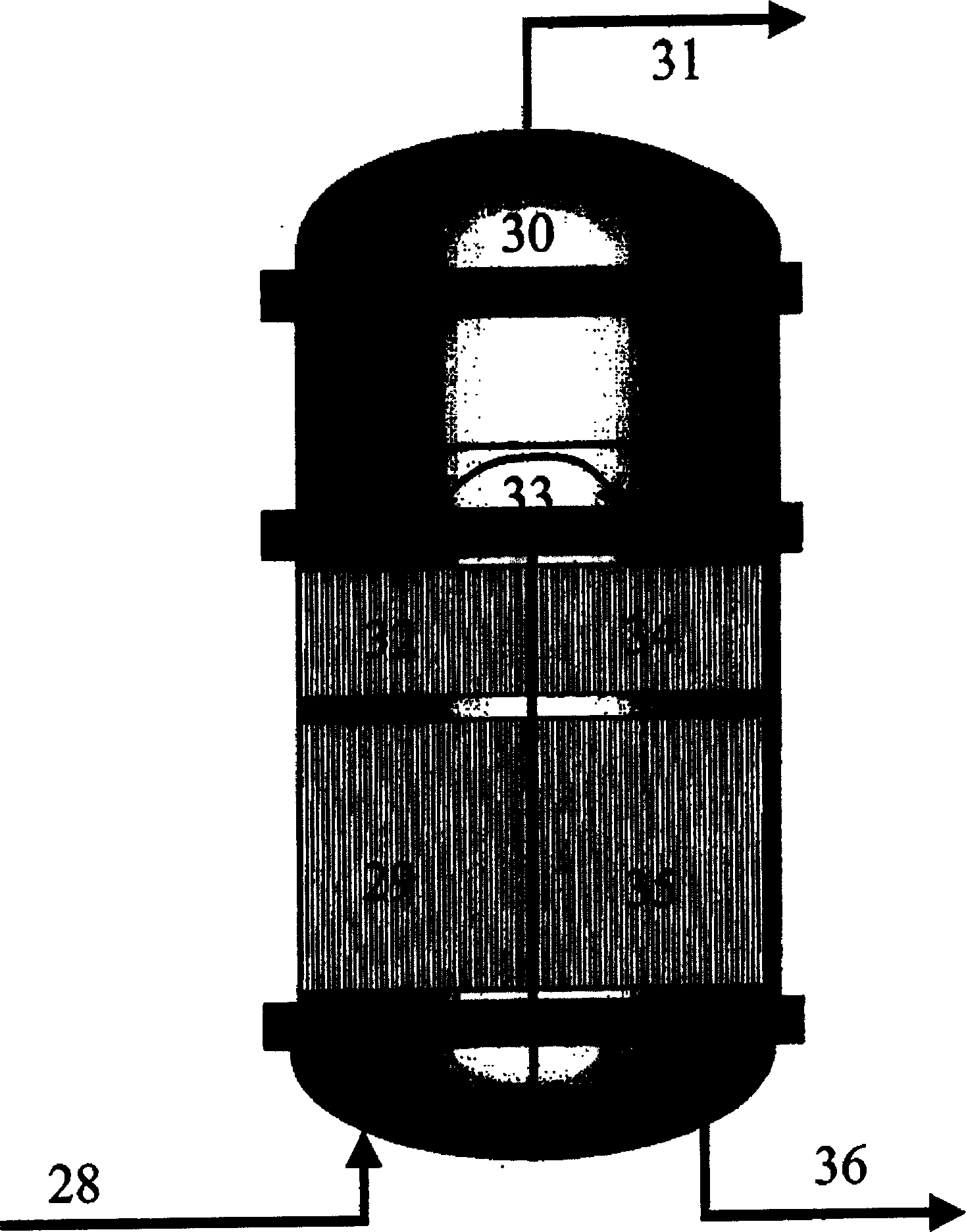

[0089] According to attached Figure 5 , the reaction part (2) is carried out in two steps. The reactor ( 29 ) consisted of a laboratory tubular reactor operating isothermally at 120° C. with a catalyst volume of about 310 ml. The catalyst used was Amberlyst 15. The second reactor ( 35 ) likewise consisted of a laboratory tubular reactor operating isothermally at 120° C. with a catalyst volume of about 310 ml. The catalyst used was also Amberlyst 15. Use heatable containers for intermediate evaporation.

[0090] The column diameters of columns (4), (6), (9) and (16) are each 50 mm. Use metal fillers. About 30 theoretical tra...

Embodiment 2

[0096] in the attached figure 1 The production of isobutene in the shown plant is characterized by the absence of water separation using module ( 21 ), so that streams 3 and 3A have the same composition. Fresh water flow (20) and waste water flow (3B) are eliminated. The waste water stream (19) is discharged directly.

[0097] The reaction part (2) is completed in one step. Reactor (2) consisted of a laboratory tubular reactor operating isothermally at 120° C. with a catalyst volume of about 285 ml. The catalyst used was Amberlyst 15. The column diameters of columns (4), (6), (9) and (16) are each 50 mm. Metal fillers (Pall rings) are used in each case. About 30 theoretical trays are installed in the column (4), and the addition of the reactor discharge (3) is carried out on the 20th theoretical tray from the top. Reflux (14) is fed to tray 1 from the top of the column. About 18 theoretical stages are installed in the column (6), the feed (5) from the column (4) is int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com