Photochromic optical article

A technology of photochromic and photochromic materials, applied in optics, optical components, layered products, etc., can solve problems such as scratches or stains on photochromic coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0232] In the following examples, a 6.25 base, 74 mm semi-finished plastic lens prepared from diethylene glycol bis(allyl carbonate) was used. The test lenses were etched with 12% potassium hydroxide at 60°C for 4 minutes and then rinsed with water. The lenses were then washed with warm soapy water, rinsed with deionized water and dried with compressed air. A very thin primer, such as a monomolecular primer, is dispensed on the surface of the lens by spin coating. The primer composition is 89.6% diglyme solvent, 10% 3-(trimethoxysilyl)propyl methacrylate and 0.4% triphenylsulfonium salt of phosphorous hexafluoro , a cationic photoinitiator. The base coat was cured by exposing to UV light for 4 seconds.

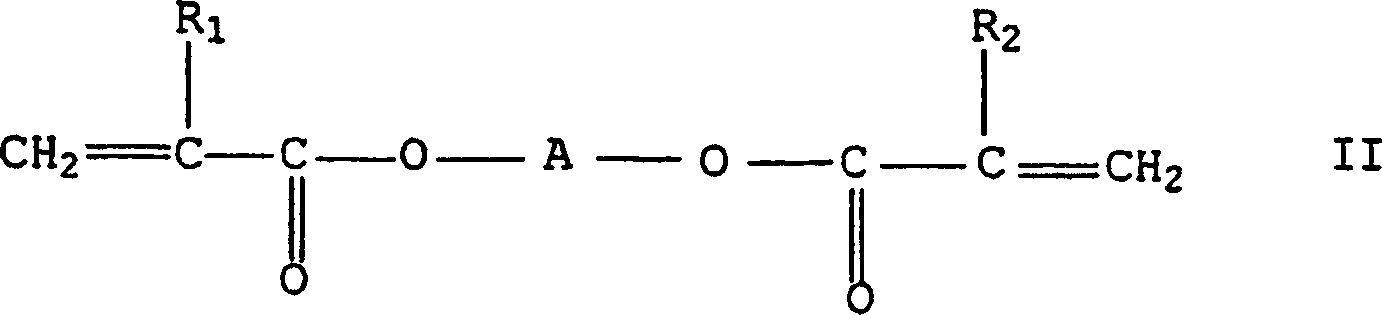

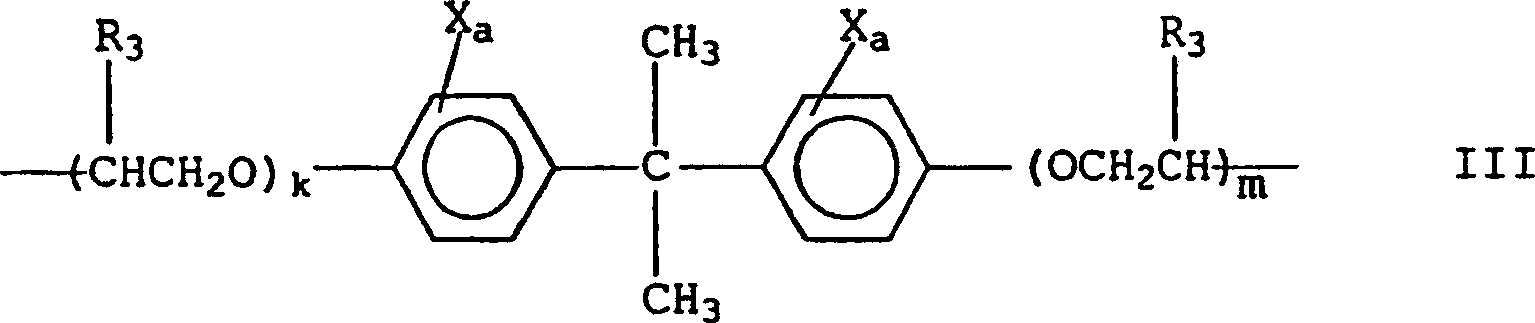

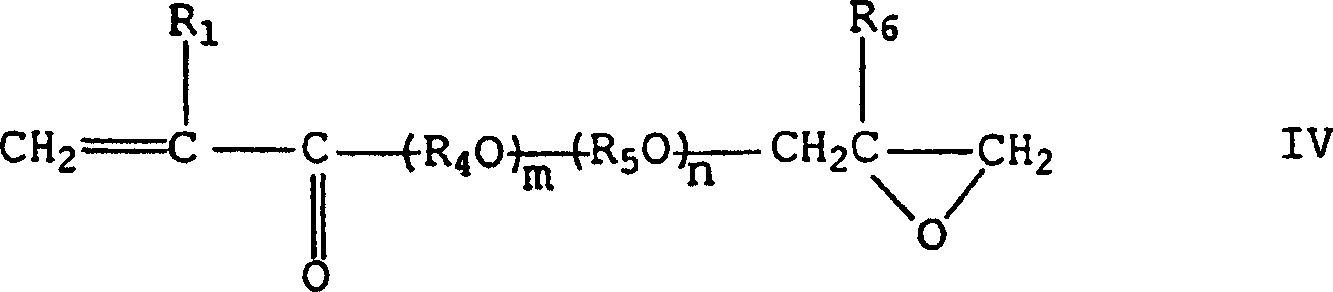

[0233] The photochromic methacrylic coating composition is made using 7.4% alkoxysilylalkyl methacrylate monomer, 7.4% trimethacrylate monomer, 59.4% dimethacrylate functional Monomer, 2.97% [1,2-b]naphthyran photochromic compound, 18.6% organic solvent, 3.7% antioxidant I...

Embodiment 2

[0250] In the following examples, a 6.25 base, 74 mm semi-finished plastic lens prepared from diethylene glycol bis(allyl carbonate) was used. The test lenses were etched with 12% potassium hydroxide at 60°C for 4 minutes and then rinsed with water. The lenses were then washed with warm soapy water, rinsed with deionized water and dried with compressed air. A very thin primer, such as a monomolecular primer, is distributed on the surface of the lens by spin coating. The primer composition is 89.6% diglyme solvent, 10% 3-(trimethoxysilyl)propyl methacrylate and 0.4% triphenylsulfonium salt of phosphorous hexafluoro , a cationic photoinitiator. The base coat was cured by exposure to UV light for 4 seconds.

[0251] The photochromic methacrylic coating composition uses about 7.8% alkoxysilylalkyl methacrylate monomer, 7.8% trimethacrylate monomer, 62.7% dimethacrylate Functional monomer, 4.7% [1,2-b]naphthyran photochromic compound, 11.8% organic solvent, 1.7% antioxidant Irg...

Embodiment 3

[0275] In the following examples, 70 mm semi-finished plastic lenses prepared from optical quality organic polymer substrates were used. The test lenses were washed with soapy water, rinsed with clean water, sprayed with isopropanol and dried. The test lenses were plasma treated for one minute using the Plasmatech machine set at 100 watts while oxygen was introduced into the vacuum chamber of the Plasmatech machine at a rate of 100 ml / min. A photochromic polyurethane coating (of the type described in U.S. Patent 6,187,444 B1) was applied to the plasma treated lens and cured thermally. The photochromic polyurethane coating is approximately 20 μm thick. The coated test lens was then washed and dried, and the photochromic coating was treated with plasma for 5 minutes using a Plasmatech machine set at a power of 400 watts while oxygen was introduced at a rate of 200 ml / min into the In the vacuum chamber of a Plasmatech machine. Three acrylate-based formulations were prepared wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com