Fluorescent lamp, bulb shaped fluorescent lamp and light fixtures

A technology for fluorescent lamps and light bulbs, applied in lighting devices, independent lighting devices, lighting and heating equipment, etc., can solve the problem of reducing the beam of fluorescent lamps, achieve good beam increase, small set particle size, and inhibit the increase of BET specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

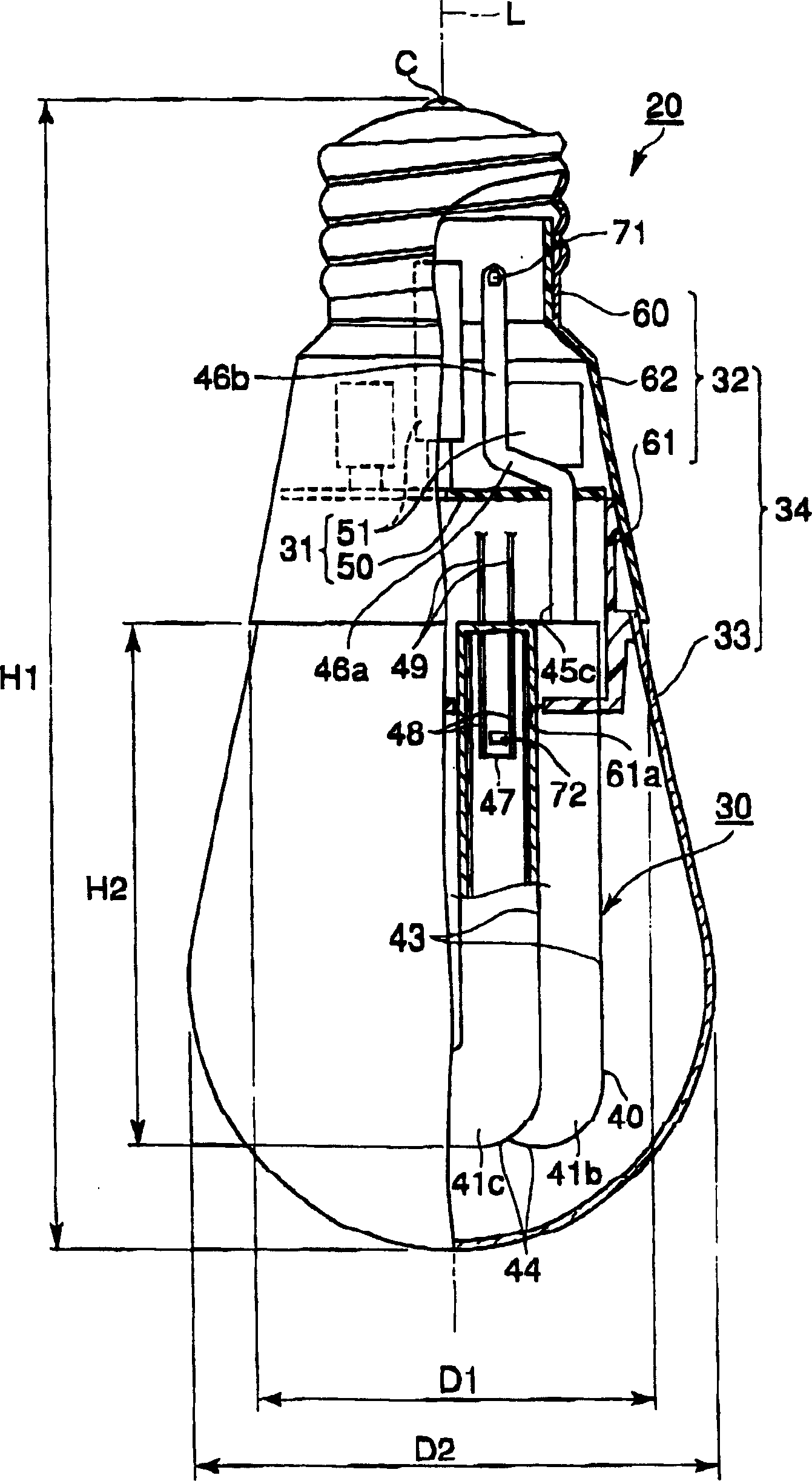

[0072] Hereinafter, refer to the Figure 1-Figure 3 , the first embodiment of the present invention will be described.

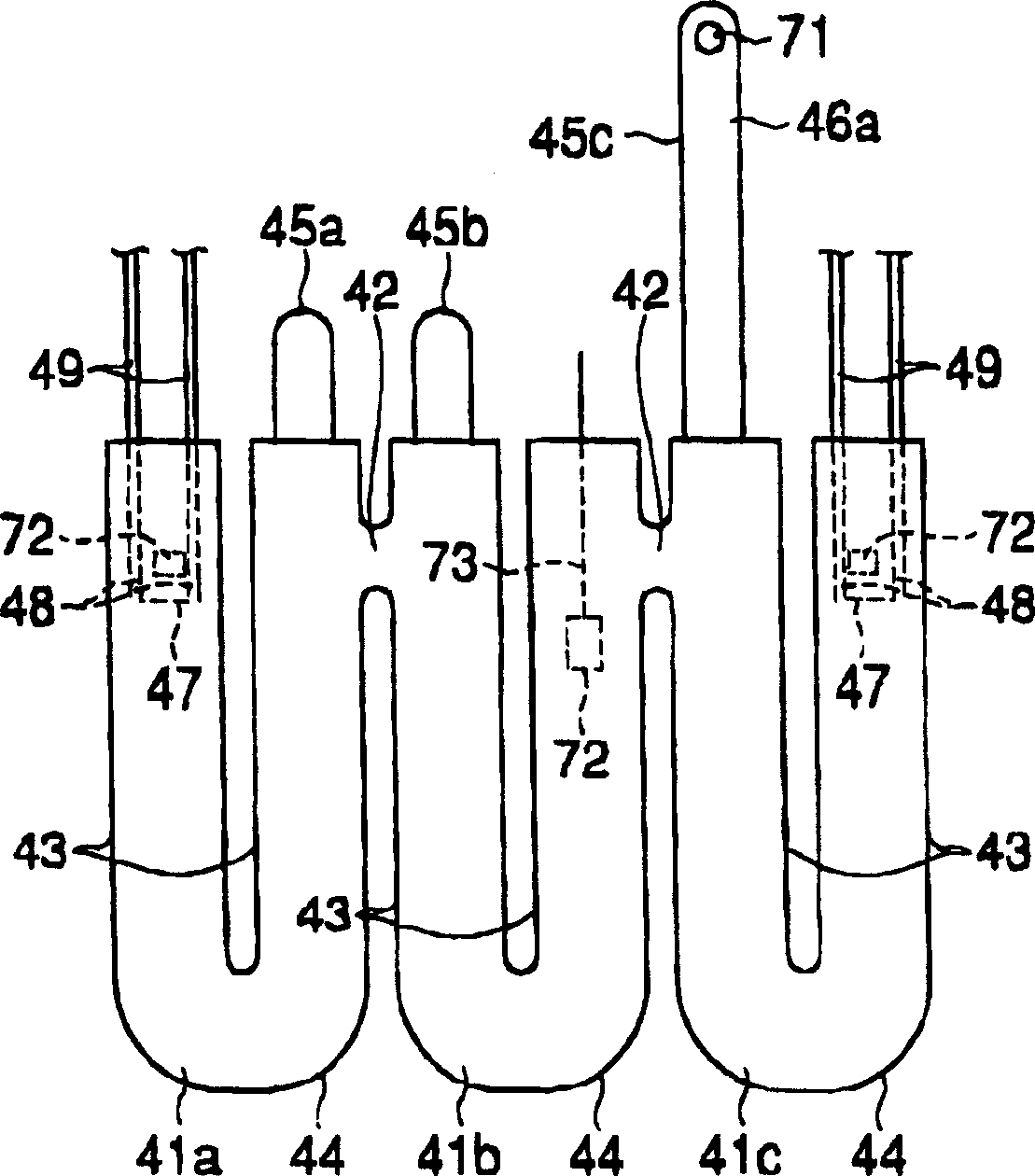

[0073] Such as figure 1 As shown, the bulb-shaped fluorescent lamp 20 has triple U-shaped fluorescent lamps 30, a lighting device 31 having a base 50 and electronic components 51, a cover 32 having a base 60 and a holder 61 as a holding part, and a bulb 33. The housing 34 composed of the cover 32 and the bulb 33 is formed to have an outer shape close to the standard size of a general lighting bulb such as an incandescent bulb with a rated power equivalent to 40W. That is to say, the height H1 including the lamp base 60 is about 110-125 [mm], the diameter, that is, the outer diameter D1 of the bulb 33 is about 50-60 [mm], and the outer diameter of the cover body 32 is about 40 [mm]. In addition, the so-called light bulbs for general lighting are light bulbs standardized in accordance with JISC7501.

[0074] The fluorescent lamp 30 includes a light-transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com