Use of humic acid sodium/potassium for deodorizing rubbish as biochemical deodorizer, its preparation method and deodorizing method

A technology of sodium humate and deodorant, which is applied in the direction of deodorization, waste disinfection or sterilization methods, disinfection, etc. It can solve the problems of large floor area, slow deodorization time, and deodorant can not achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, take by weighing 500 kilograms of weathered coal, put into reactor, add 42.5 kilograms of sodium hydroxide, 2000 kilograms of waters to react, pH value is controlled at 9~11, and reaction temperature is about 90 ℃, must not exceed 130 ℃, time After about 1 hour, put the sodium humate solution into the sedimentation tank for natural precipitation, about 3-5 days, after measuring the humic acid content meets the requirements, then pump the original solution into the downstream centrifugal spray drying tower for drying , the diameter of the drying tower is 5 meters, the tower height is 6 meters, the speed of the main engine is 7100 rpm, and the exhaust air volume is 30000m 3 , the inlet air temperature is 320-380°C, and the tail gas is evacuated by cyclone separation. After the above-mentioned drying, a black powdery or granular sodium humate product is obtained.

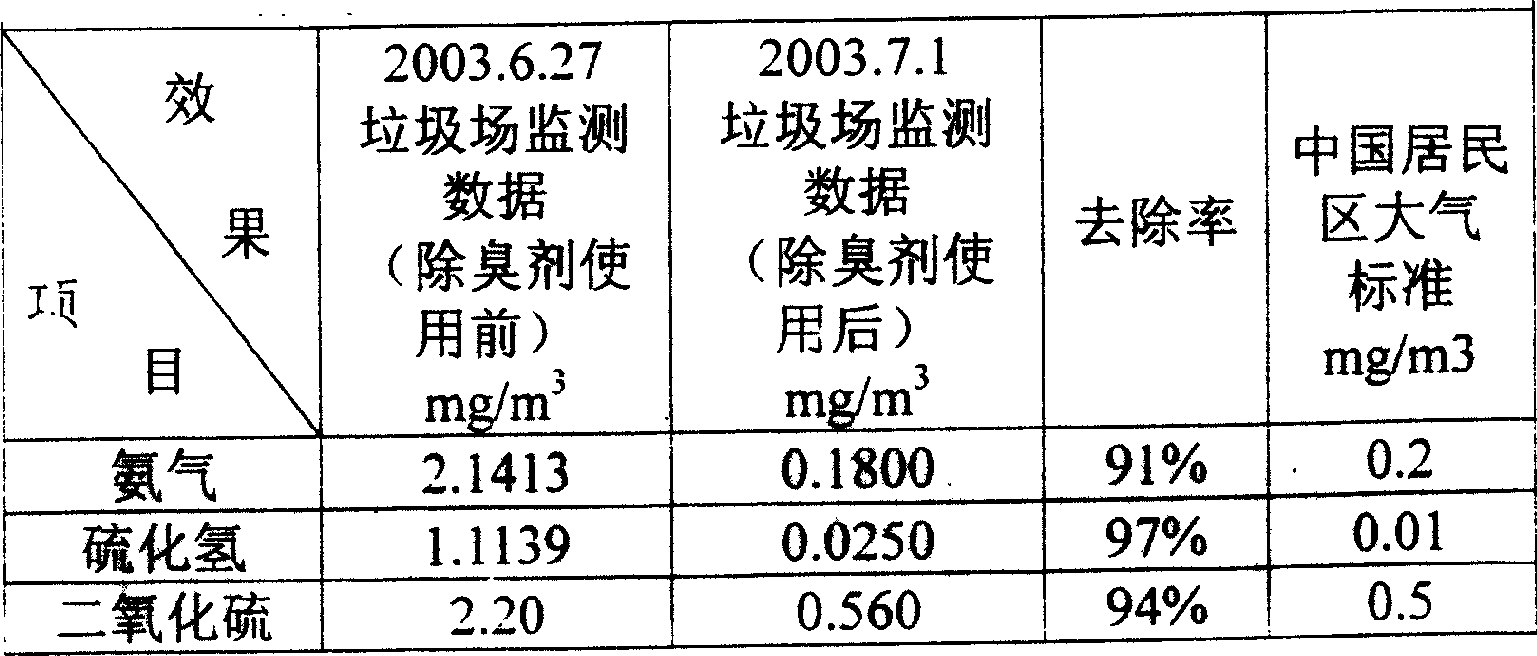

[0045] Garbage deodorization method and effect:

[0046] 1. Experiment site: Garbage Station ...

Embodiment 2

[0051] Embodiment 2, take by weighing 200 kilograms of peat or lignite altogether, put into reactor, add potassium hydroxide 18 kilograms, water 1000 kilograms react, process parameter control and the preparation process thereafter are the same as example 1.

[0052] Deodorization method of use: first take 1 kg of the powder or granular potassium humate deodorant obtained above and compound it into a colloidal solution according to the weight of 1:10, and then according to the weight ratio (kg) of the colloidal solution and water to 1:10, At the same time, add about 1 kg of sucrose or fructose, put it into a sealed container, and anaerobically ferment it for about 20 days at 25 ° C ~ 35 ° C until the aroma of sweet and sour wine is produced. After the water weight ratio is 1:50, it is sprayed on the garbage, and the garbage is mixed well, and the soil is rolled and compacted, which can quickly eliminate the odor and keep it for an appropriate time to achieve the eradication of ...

Embodiment 3

[0053] Embodiment 3, take by weighing 300 kilograms of lignite, pulverize, put into reactor, add 25.5 kilograms of sodium hydroxide, 1500 kilograms of waters to react, reaction solution is put into three sedimentation tanks, slag is deposited on the bottom of the tank, and solution flows into the first In the second and third pools, measure the content of sodium humate and adjust the pH value to 9-11. The resulting product is sodium humate jelly liquid, which is packaged in containers, which saves investment in expensive drying equipment.

[0054] How to use deodorant:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com