Ideal oxygen precipitating silicon wafers with nitrogen/carbon stabilized oxygen precipitate nucleation centers and process for making the same

An oxygen precipitation and stabilization technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as loss of IG potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

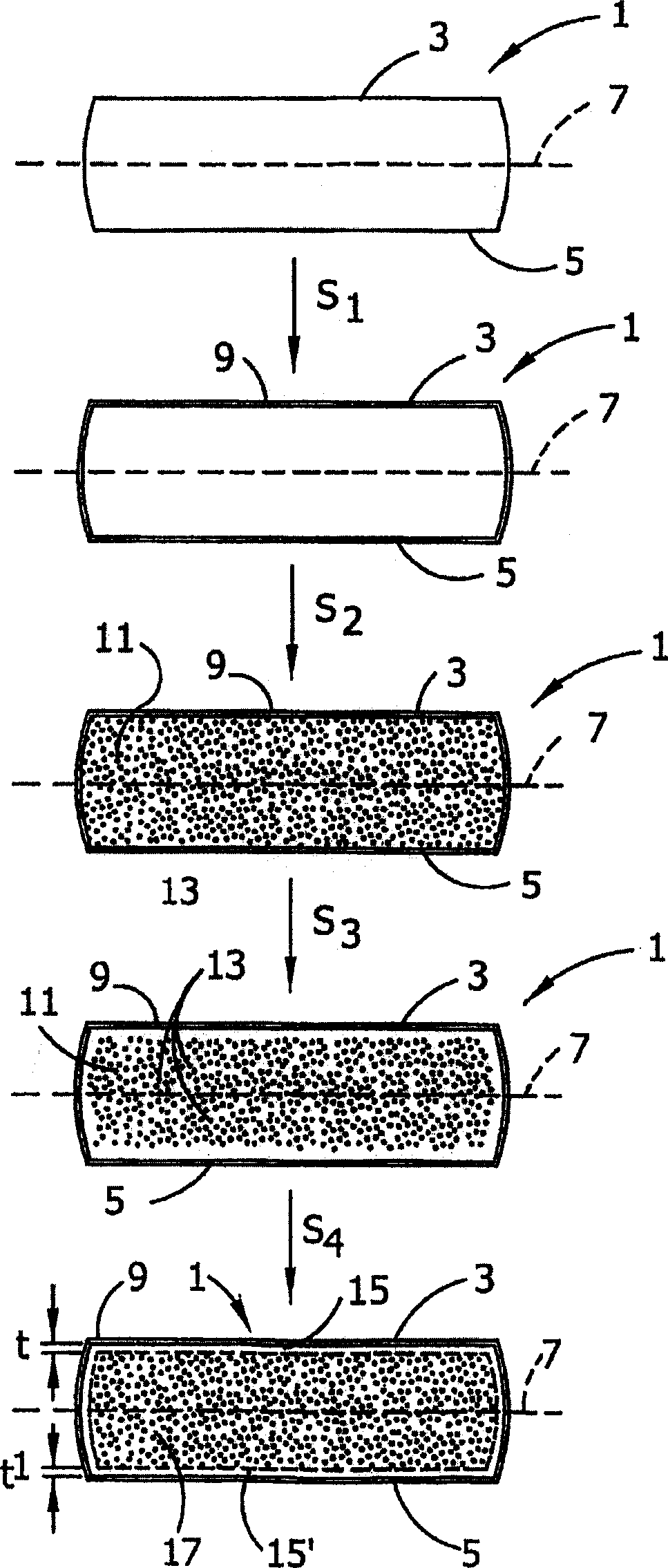

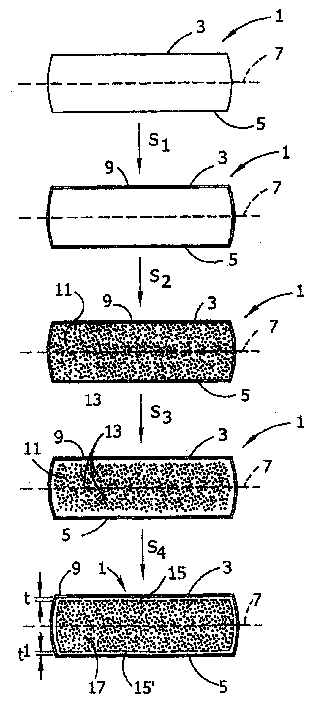

[0015] In accordance with the present invention there is disclosed an ideally deposited wafer which will form a clean zone of sufficient depth and a wafer body containing a sufficient density of oxygen deposits during essentially any electronic device fabrication process , the above oxygen precipitates are used for IG (intrinsic gettering) purposes. Advantageously, such ideally deposited wafers can be produced without problems using tools commonly used in the semiconductor silicon manufacturing industry. This method creates a "template" in the silicon that dictates or "prints" the way in which oxygen eventually precipitates. According to the invention, this template is stabilized such that it can undergo subsequent rapid thermal treatments (eg epitaxial deposition and / or oxygen implantation) without intervening thermal stabilization anneals.

[0016] A. Original material

[0017] The starting material for the desired deposited wafers of the present invention is a single crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com