Long persistence luminescent glass and manufacturing method thereof

A technology of long afterglow luminescence and luminescent glass, which is applied in the field of material glass, and can solve the problems of low content of luminescent materials, affecting the afterglow brightness of luminescent glass, and narrow application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Preparation of long afterglow luminescent glass powder

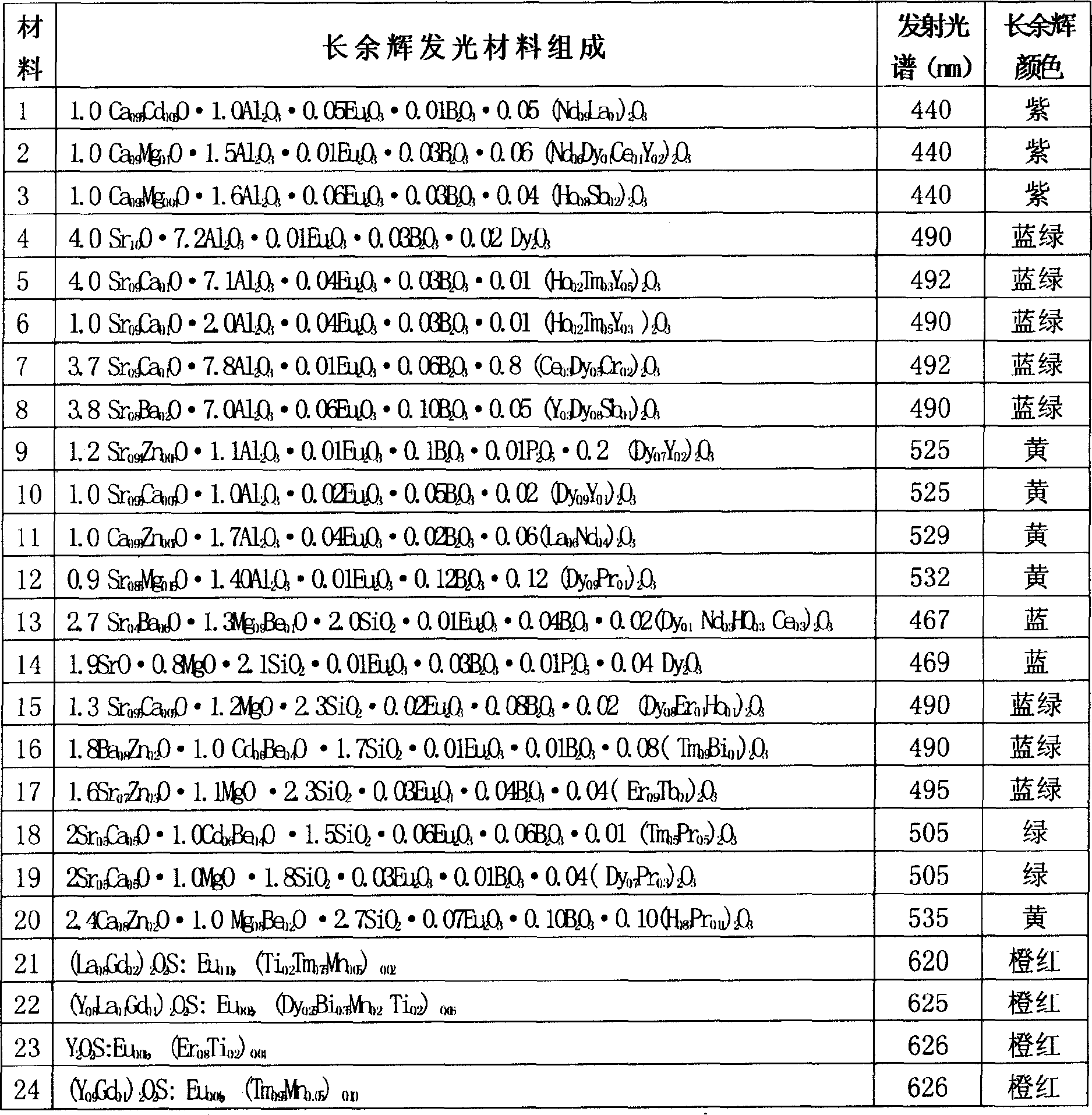

[0077] Mix 400g of long-lasting luminescent material 14 particle size: 10-65μm and 600g matrix glass powder 6#, particle size 60-150μm, and mix uniformly to prepare luminescent glass powder specially used for producing long-lasting luminescent glass. The glass powder is irradiated with visible light for 10 minutes, and it can emit blue light in the dark, with an afterglow of more than 10 hours.

[0078] The above process is also applicable to long afterglow luminescent materials 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 16, 17, 18, 19, 20, 21, 22 , 23, 24 can produce purple, blue, blue-green, yellow-green, yellow, orange-red, white, pink and other long-lasting luminescent glass powders, which can be used as raw materials for producing long-lasting luminous glass.

[0079] The matrix glass powder formula of the above process can also be applied to 3# and 4#.

Embodiment 2

[0081] Preparation of long afterglow luminescent glass block

[0082] Put the long-lasting luminescent glass powder (400g long-lasting luminescent material 10, particle size: 10-65μm and 600g matrix glass powder 6#, particle size: 50-100μm), put it in the mold of the hydraulic press and press it into a blank with a pressure of 2.2MPa , sintered in an air atmosphere at 740°C for 30min in a heating furnace, quenched in water, crushed and sieved to obtain a long afterglow luminescence glass block (particle size 0.5-5.mm), which is used as a raw material for the production of long afterglow luminescence glass. After the glass block is irradiated with visible light for 10 minutes, it can emit yellow-green light in the dark, and the afterglow lasts for more than 10 hours.

[0083] The above process of sintering at 800°C is also applicable to long afterglow luminescent materials 1, 2, 3, 4, 5, 6, 7, 8, 9, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24.

Embodiment 3

[0085] Put the long afterglow luminous glass powder (composed of long afterglow luminescent material 4, particle size: 10-30μm, 48g and matrix glass powder 3#, particle size: 60-150μm, 72g) in the hydraulic press mold with a pressure of 3.2MPa Pressed into a blank, sintered in an air atmosphere at 850°C for 40 minutes in a heating furnace, and then cooled down to room temperature at a speed of 18°C / min with the furnace, and a long-lasting blue-green milky white long-lasting luminous glass was produced. This glass can be cut, ground, drilled and processed into any shape. The long-afterglow luminous glass emits blue-green in a dark place after being irradiated with visible light for 10 minutes, and the afterglow lasts for more than 10 hours.

[0086] The above process of sintering at 800°C is also applicable to long afterglow luminescent materials 1, 2, 3, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24 can produce purple, blue, blue-green, green, yell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com