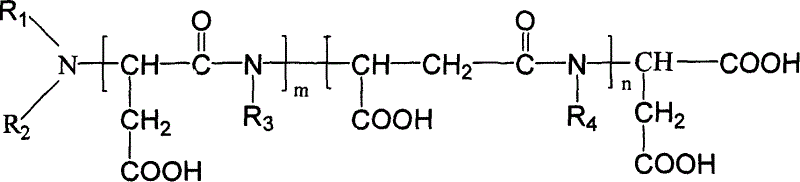

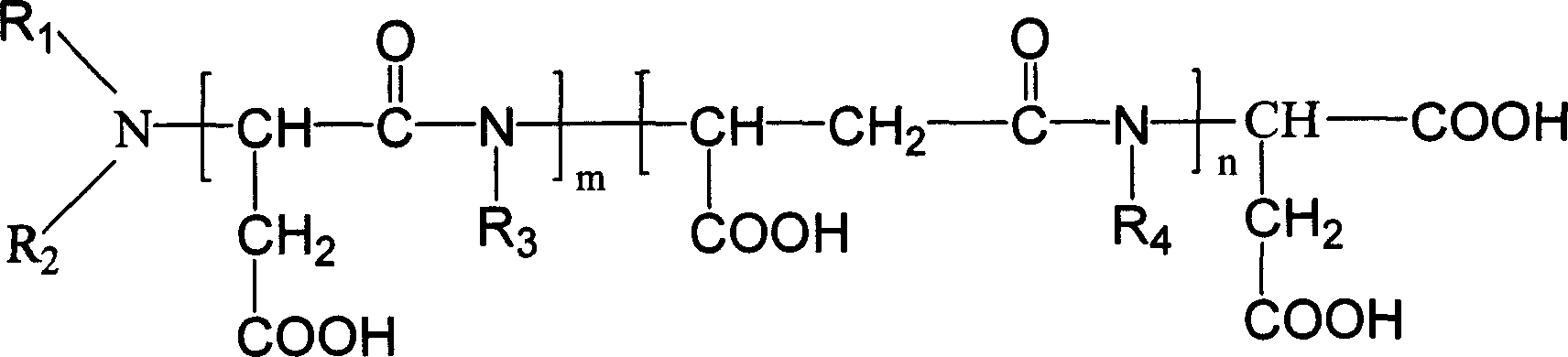

Composite anti-dirty corrosion inhibiting agent and application thereof

A technology of scale and corrosion inhibitors and copolymers, which is applied in the directions of scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. Corrosion performance, good scale inhibition performance, and good scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in the four-necked flask equipped with stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20° C.), 26.6 g of formaldehyde aqueous solution (36% of active ingredients) was added. Control the reaction temperature below 50° C. with a cold water bath, and add 45.2 g of phosphorus trichloride dropwise (the active ingredient is calculated as 97%). After the dropwise addition of phosphorus trichloride is complete, raise the temperature to 70±2°C and keep it warm for 2 hours, then cool to obtain the product. The organic phosphine content of the product was 8.2%.

Embodiment 2

[0071] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in the four-necked flask equipped with stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20° C.), 26.6 g of formaldehyde aqueous solution (36% of active ingredients) was added. Control the reaction temperature below 50° C. with a cold water bath, and add 45.2 g of phosphorus trichloride dropwise (the active ingredient is calculated as 97%). After the dropwise addition of phosphorus trichloride is complete, raise the temperature to 105±2°C and keep it warm for 2 hours, then cool to obtain the product. The organic phosphine content of the product was 7.3%.

Embodiment 3

[0073] Add polyaspartic acid (produced by Changmao Biochemical Engineering Co., Ltd., content: 40%, molecular weight: 4000-5000) in the four-necked flask equipped with stirrer, reflux condenser, constant pressure dropping funnel and thermometer 91.6g and 157ml of water, start stirring to fully dissolve polyaspartic acid. At room temperature (20° C.), 26.6 g of formaldehyde aqueous solution (36% of active ingredients) was added. Control the reaction temperature below 50° C. with a cold water bath, and add 45.2 g of phosphorus trichloride dropwise (the active ingredient is calculated as 97%). After the dropwise addition of phosphorus trichloride is complete, raise the temperature to 90±2°C and keep it warm for 4 hours, then cool to obtain the product. The organic phosphine content of the product is 9.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com