Magnetic control heavy current MAG welding method useful for deep groove welding and equipment thereof

A technology of welding equipment and welding method, applied in welding equipment, arc welding equipment, metal processing equipment and other directions, can solve the problems of large size, reduced magnetic field in the depth of groove, and inability to effectively control high-current MAG welding process, etc. Achieve stable droplet transfer process and good arc control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

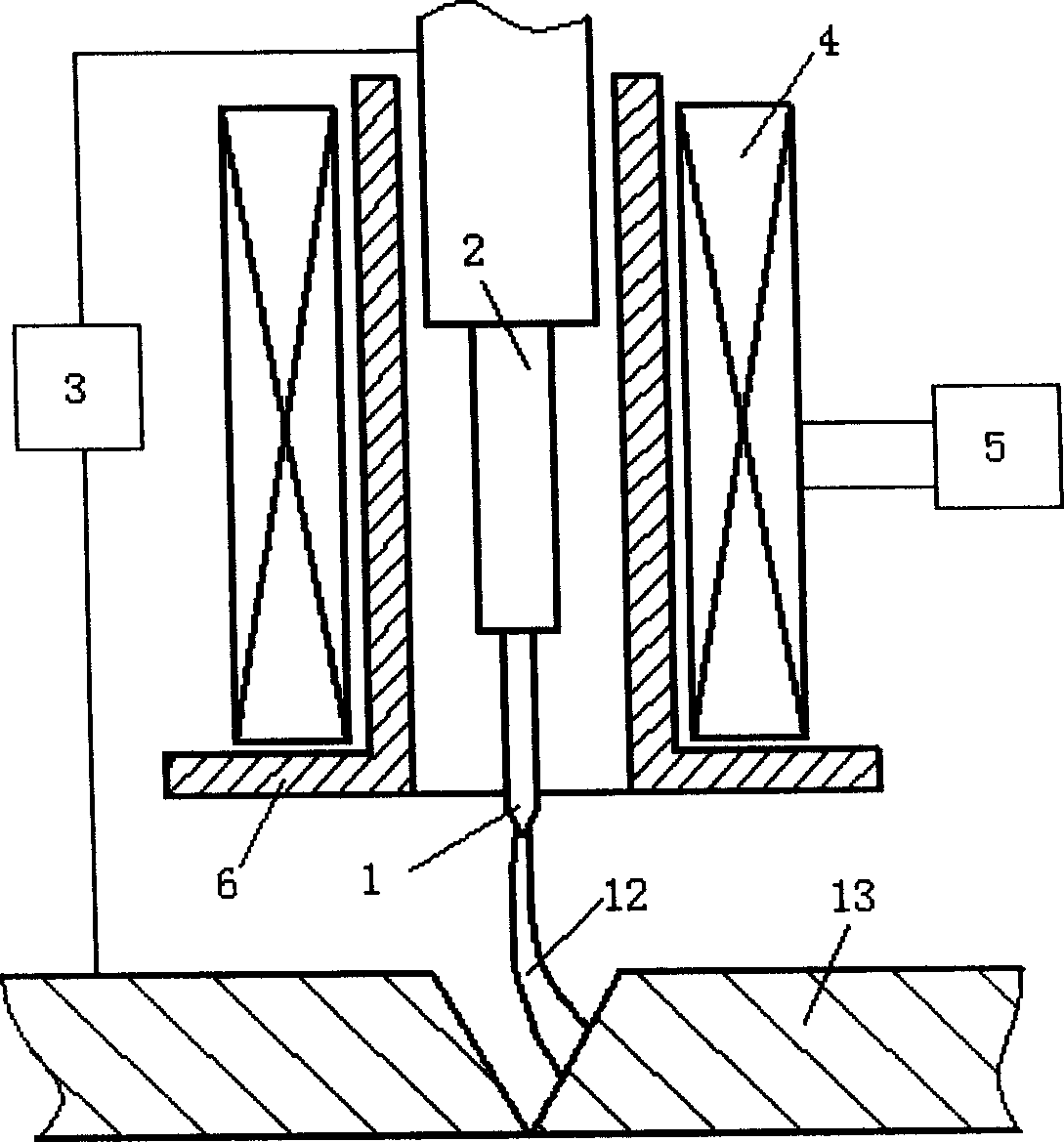

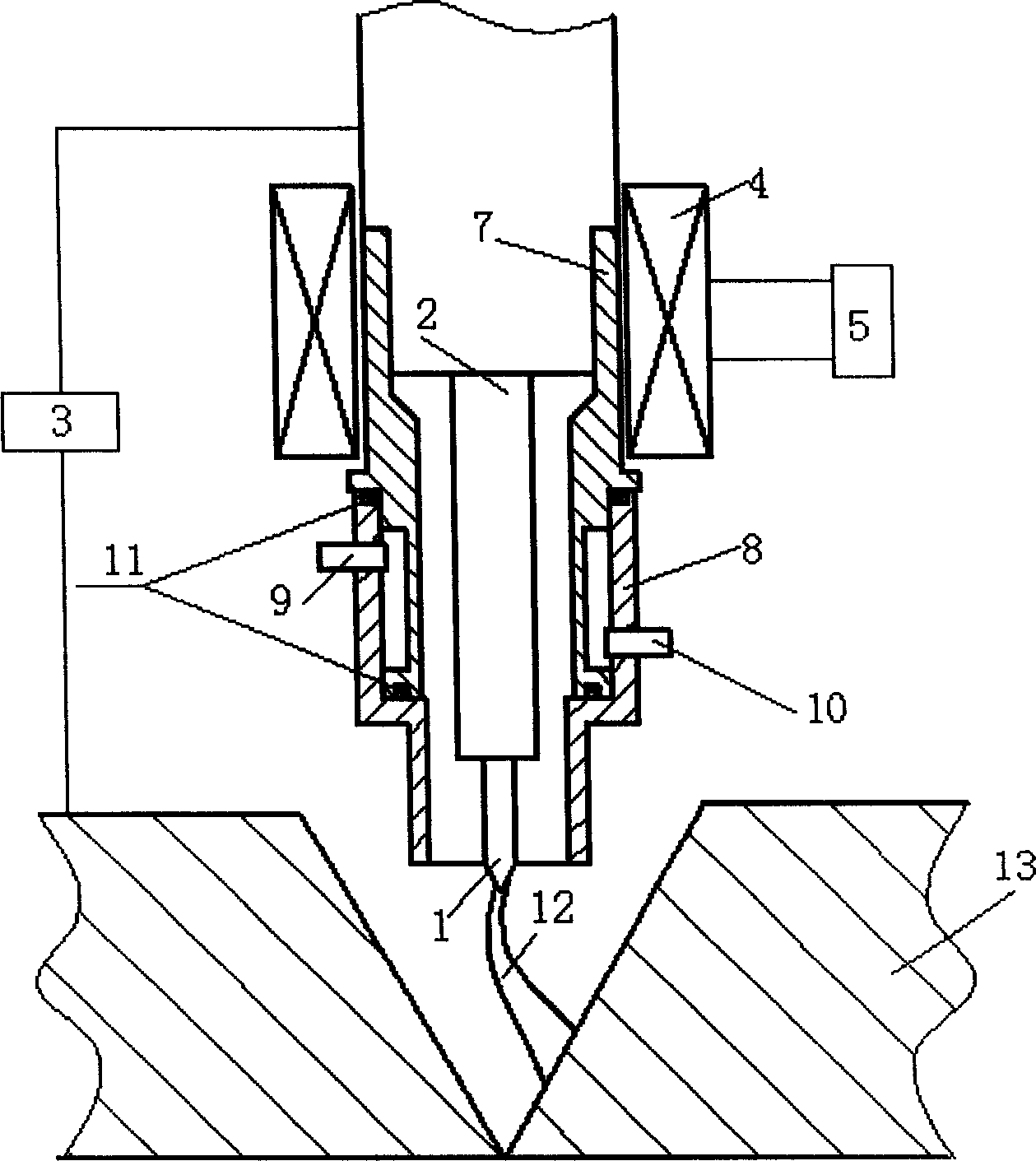

[0024] The present invention can refer to figure 2 Welding is carried out after assembly according to conventional methods, and the specific test conditions are as follows:

[0025] The material of the magnetic core is Q235, the total depth of the lower part 7 of the magnetic core is 90mm, and the total depth of the upper part 8 of the magnetic core is 138mm; the inner diameter of the lower end of the lower part 8 of the magnetic core is 22mm, the outer diameter is 28mm, and the depth is 36mm The inner diameter of the upper end of the lower part 8 of the magnetic core is 36mm, the outer diameter is 44mm, and the depth is 42mm, and the thread length of this part is 11mm; the inner diameter of the upper end of the upper part 7 of the magnetic core is 32mm, the outer diameter is 40mm, and the depth is 85mm , the thread length of this part is 18mm; the inner diameter of the lower end of the upper part 7 of the permeable core is 24mm, the outer diameter is 36mm, and the depth is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com