Electromagnetic magnetizer for engine fuel oil

A magnetizer and engine technology, applied in the field of magnetizers, can solve problems such as waste, and achieve the effects of easy portability, small space, and enlarged size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

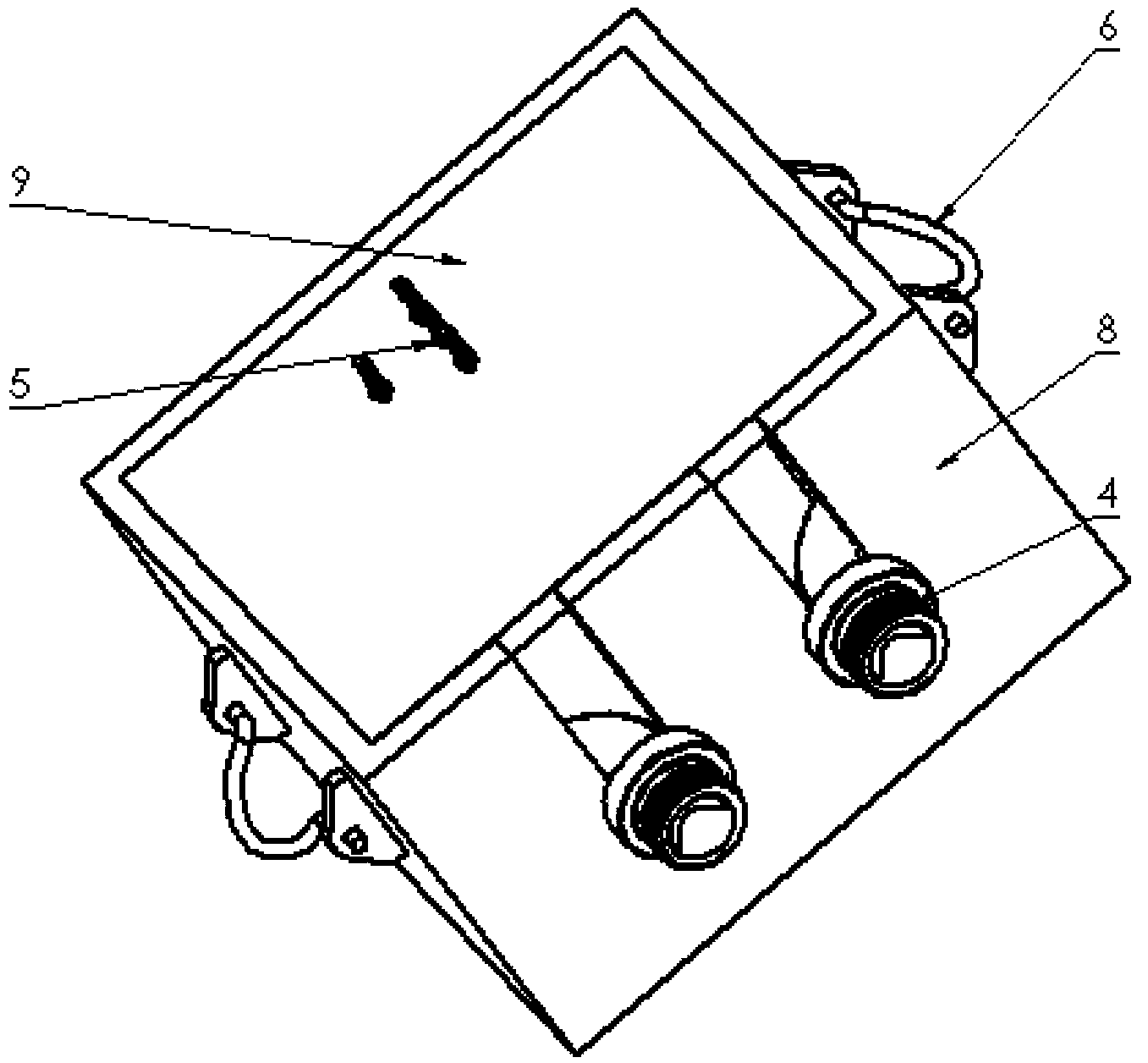

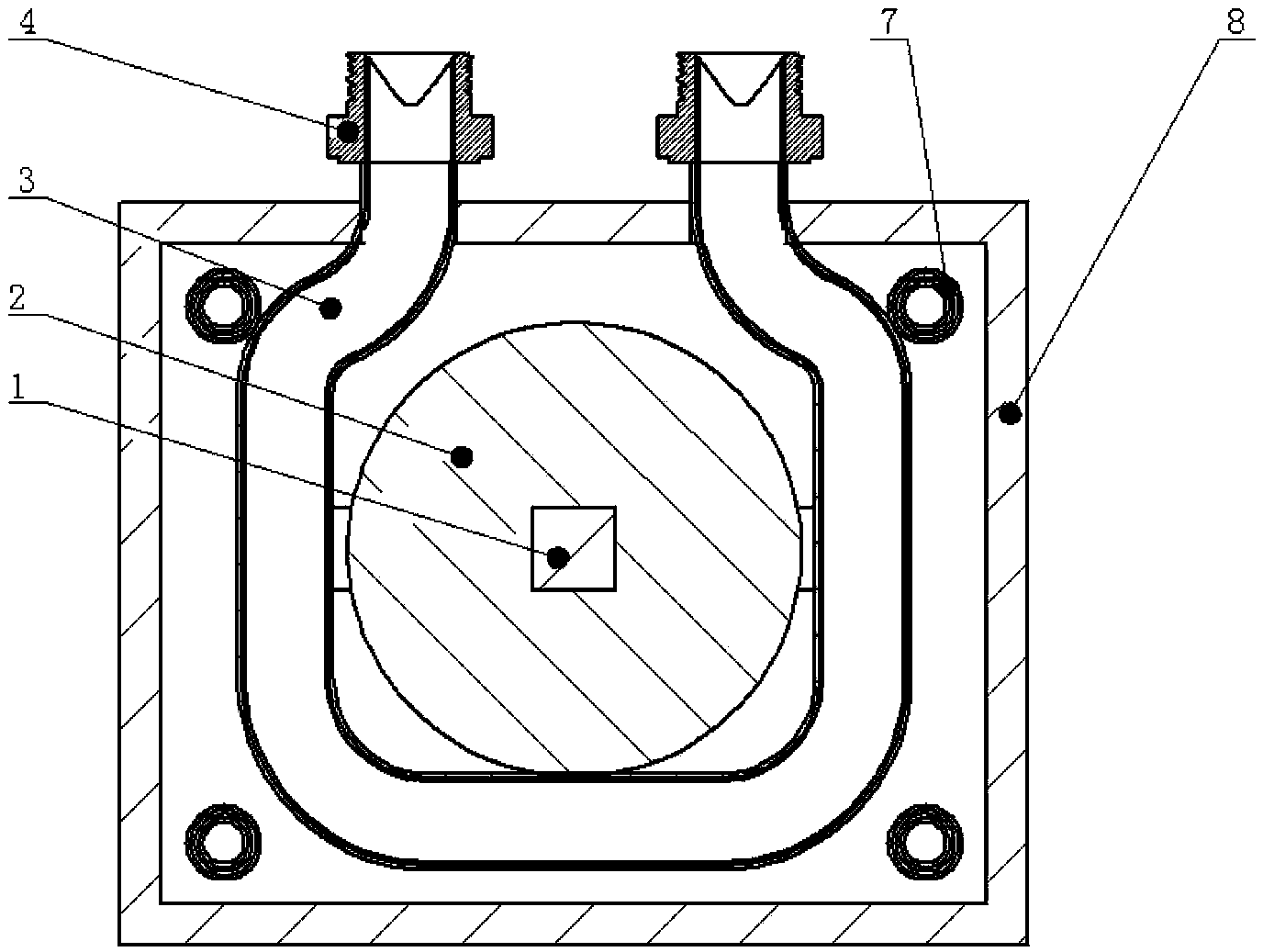

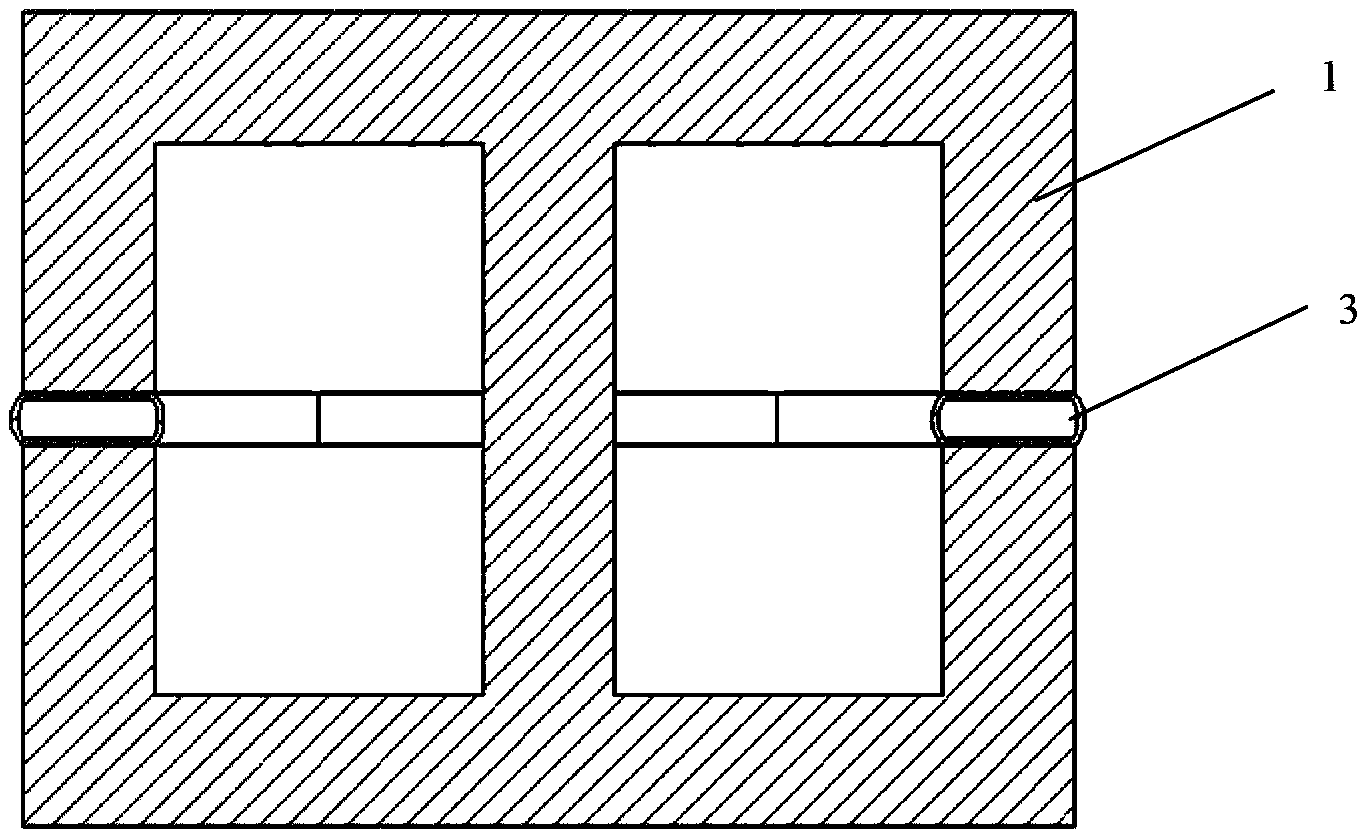

[0029] The engine fuel electromagnetic magnetizer of the invention comprises an electromagnetic magnetizer unit and a control circuit unit.

[0030] Such as Figure 1~2 As shown, the electromagnetic magnetizer unit includes a support rod 7, a metal shield 8, a cover plate 9, an iron core 1, a coil 2 and an oil pipe 3, the metal shield 8 is fixed on the support rod 7, and the cover plate 9 forms a closed space; the iron core 1 is located in the closed space formed by the metal shield 8 and the cover plate 9; the coil 2 is tightly wound on the iron core 1, and the coil 2 is wound in 1000 turns, 2000 turns, 3000 turns The positions of the turns are respectively provided with wire connectors, and the wire connectors are connected to the power connector 5 fixed on the cover plate 9, and the power connector 5 is connected to the control circuit unit through wires; The two ends of the oil pipe 3 pass through the metal shield 8 and are connected to the threaded joint 4; the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com