Automatic device in transverse direction for tracking welding line line by floatation force of welding-torch

An automatic tracking device, horizontal technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low tracking accuracy, complex tracking system, tracking error, etc., to achieve excellent anti-interference ability, simple tracking system, eliminate The effect of tracking error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

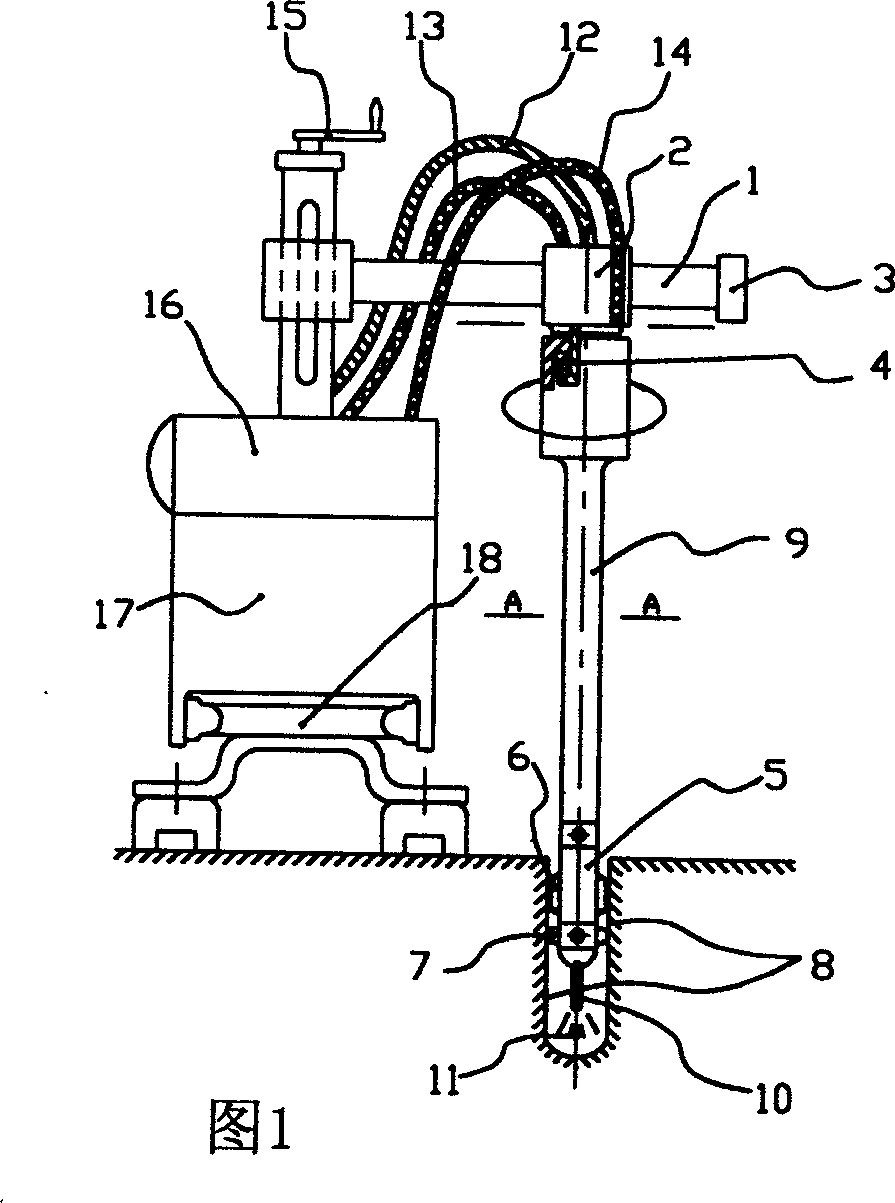

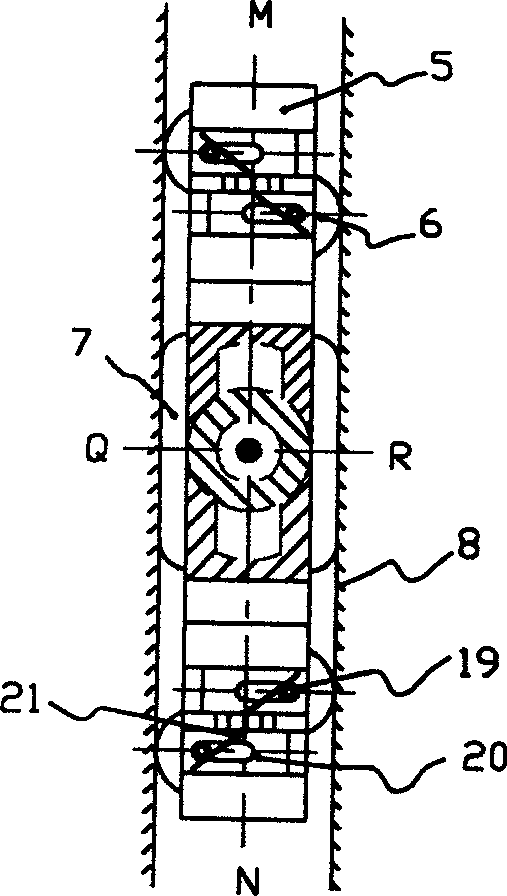

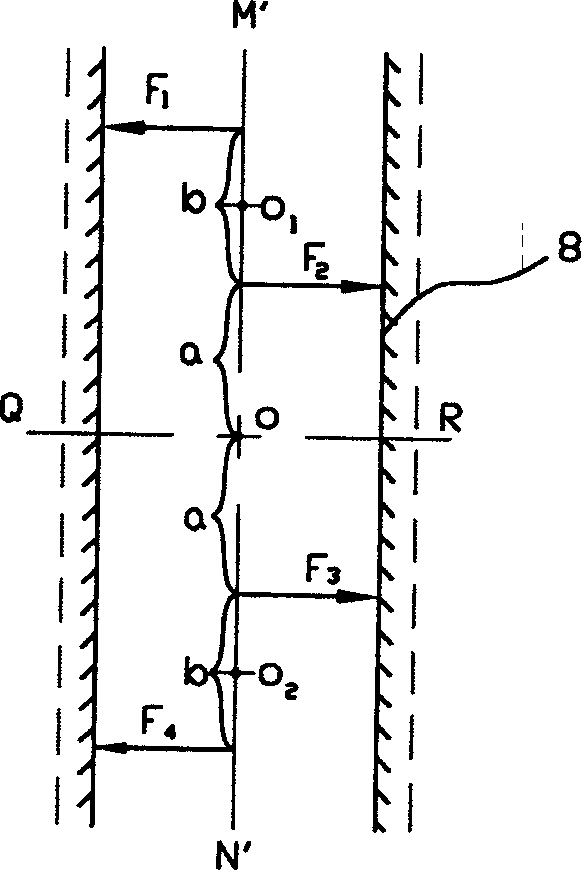

[0015] As shown in Figures 1 to 7, a welding torch floating elastic drive weld seam horizontal automatic tracking device according to the present invention has a welding trolley 17 on which a guide rod 1 for the lateral translation of the welding torch 9 is fixed; the guide rod 1 A sliding sleeve 2 that can move horizontally is connected to the top; the base end of the welding torch 9 and the sliding sleeve 2 are rotatably connected, and the other end is the welding wire outlet end, which is flat, and a plane force couple source that can be installed is fixed on the front and rear sides respectively. The force couple seat body 5 of the component; the force couple source part in each force couple seat body 5 includes two detection rollers 6 that keep the welding wire always at the center line of the welding groove and are respectively attached to the two sides 8 of the welding groove; the detection rollers 6 has the elastic part 21 that makes it can be pressed against the weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com