Steel band loop length calculating system

A computing system and steel strip technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem that the quality of the head and tail of the steel strip is also greatly affected, the impact of fixed-length shearing of finished coils, and tracking cannot be eliminated Accuracy and other issues, to achieve the effect of improving the cutting-to-length accuracy, reducing broken belts, and eliminating tracking errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

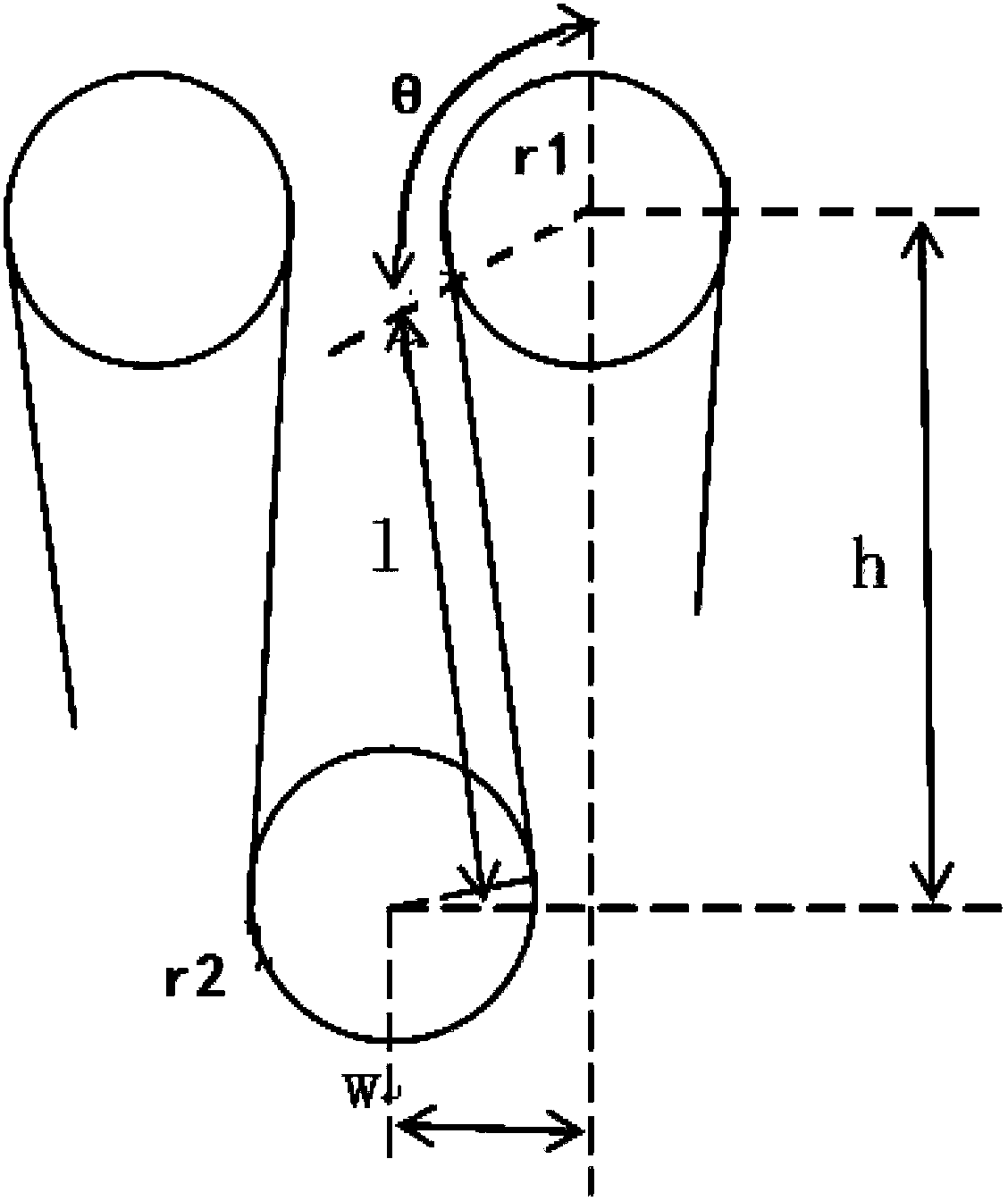

[0020] The steel belt looper calculation system is equipped with a PLC controller and an absolute encoder, where the absolute encoder is used to measure the vertical height h between the upper and lower rollers, that is, the distance between the horizontal and radial extension lines of the axes of the two rollers, The measured vertical height h signal is sent to the PLC controller.

[0021] The PLC controller is equipped with an information input unit, and the staff needs to set the upper roller diameter (radius) r 1 , Lower roll diameter (radius) r 2 , the horizontal distance w between the two rollers, and the total set amount n are input to the PLC controller. The horizontal distance between the centers of the two rollers w is the distance between the vertical extension lines of the axial centers of the two rollers.

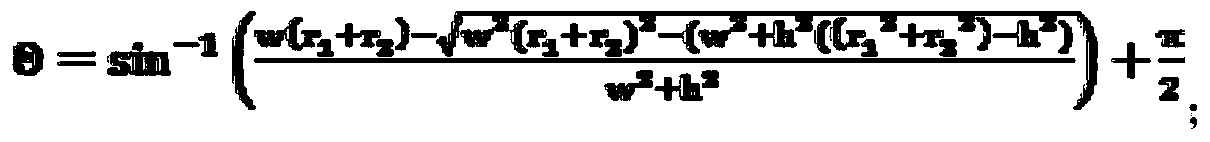

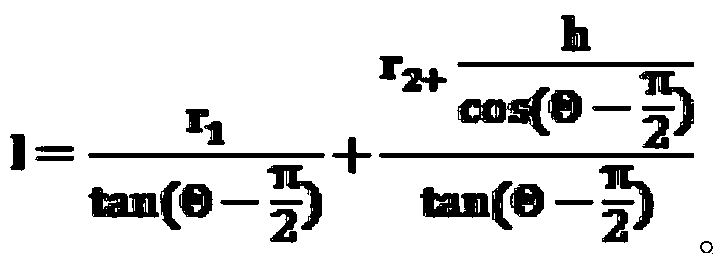

[0022] The PLC controller calculates the angle between the upper roll and the lower roll in the tangential direction of the steel strip and the vertical dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com