Apparatus for compensating for speed error of motor

A speed error, compensation motor technology, used in the control of the speed or torque of the motor, the angular single-axis angular velocity control of the AC motor, and the control of the electromechanical transmission device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

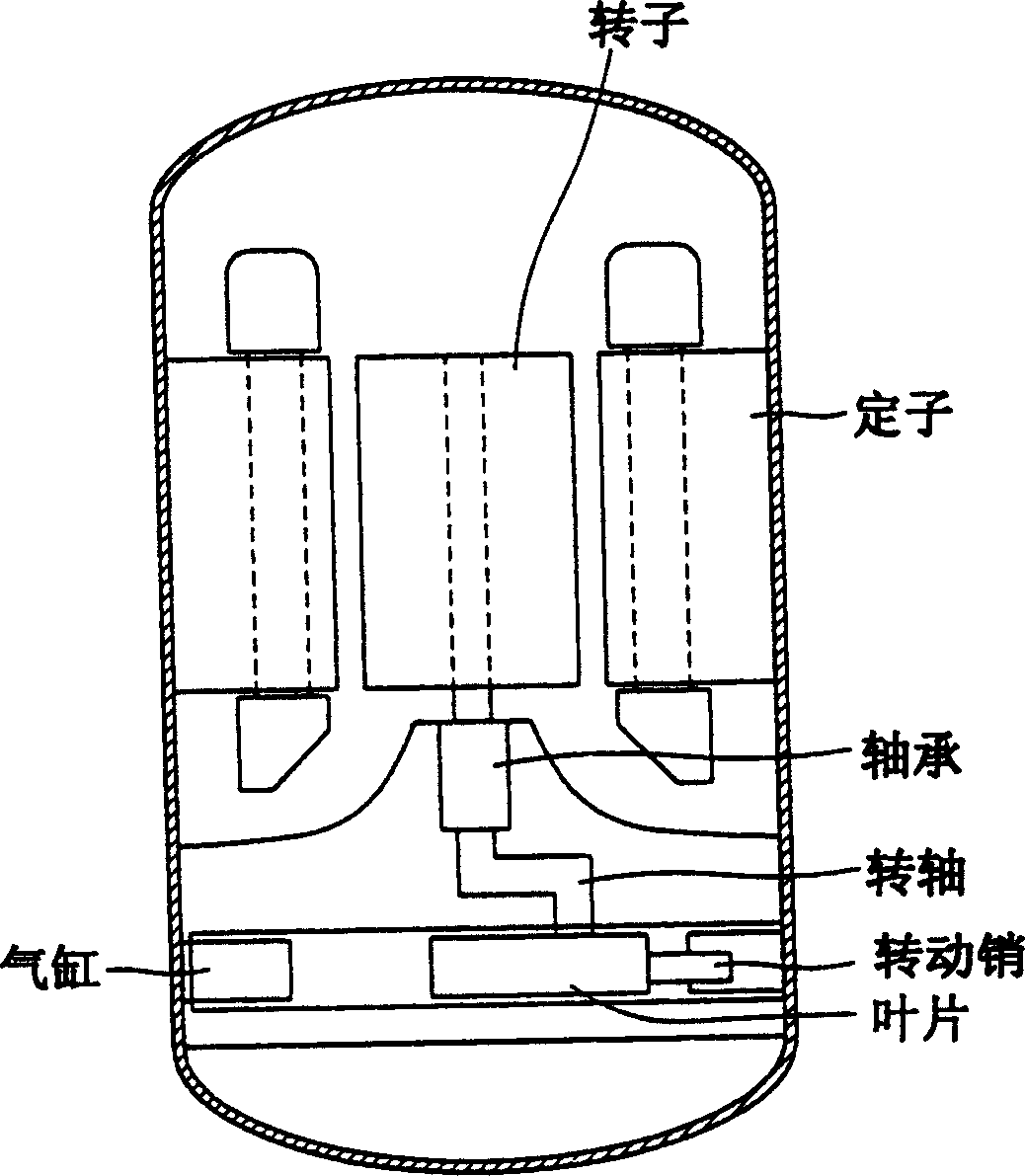

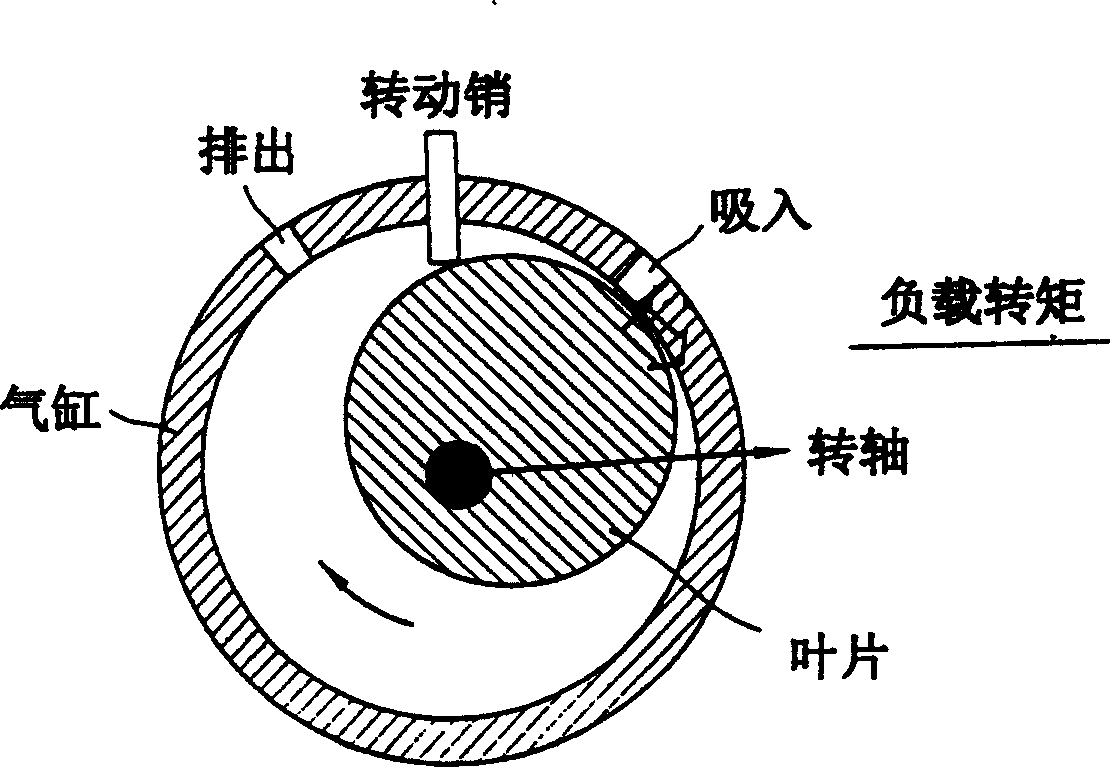

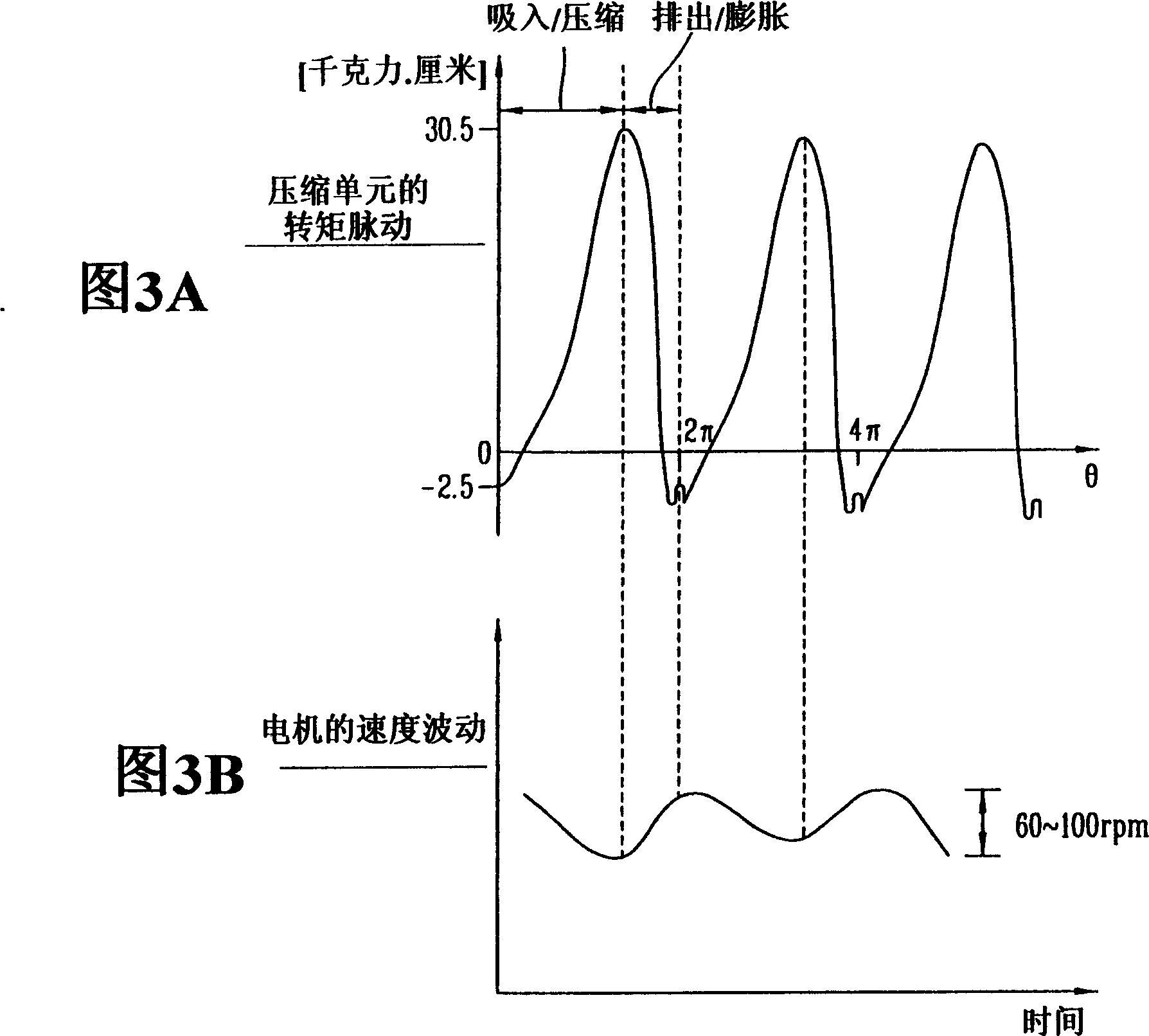

[0027] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] The following will refer to Figure 5A to Figure 7 A device for compensating the speed error of a motor in detail, which can reduce vibration and noise caused by load characteristics, and realizes its function by dividing the rotation area equivalent to a complete rotation of the rotor of the motor into a number of predetermined The turning area compares the reference speed and the previous estimated speed in each divided turning area, decides each speed compensation value, and compensates for a speed error between the reference speed and the current estimated speed based on each speed compensation value.

[0029] Figures 5A to 5C illustrate the principle of speed error compensation according to the present invention. That is to say, FIG. 5A to FIG. 5C show a method that divides the rotation area corresponding to one complete rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com